Heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]

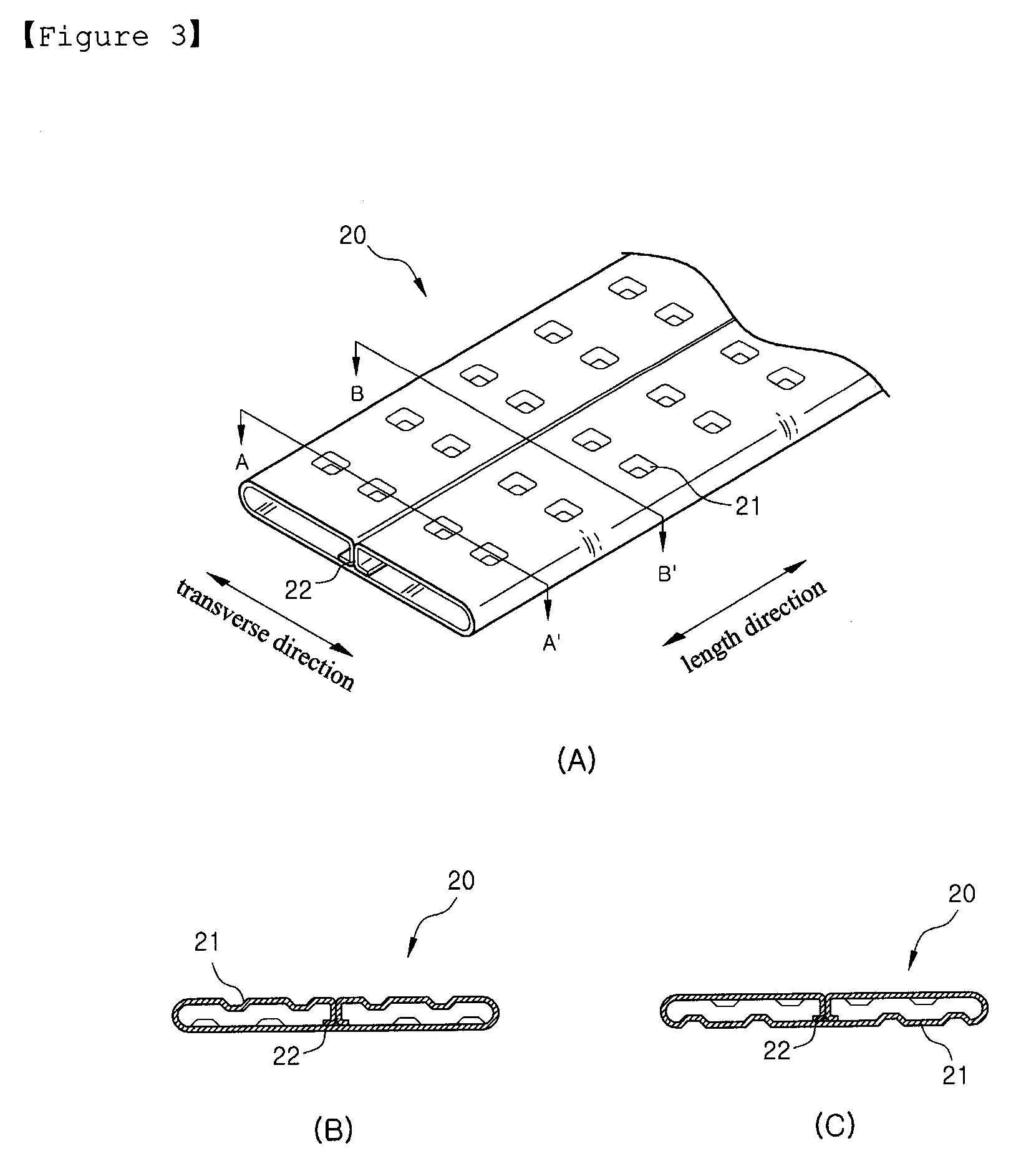

100:heat exchanger10:tank11:inlet tank12:outlet tank20:tube30:fin21:dimple22:partition wall

Best Mode

[0022]Hereinafter, the embodiments of the present invention will be described in detail with reference to accompanying drawings.

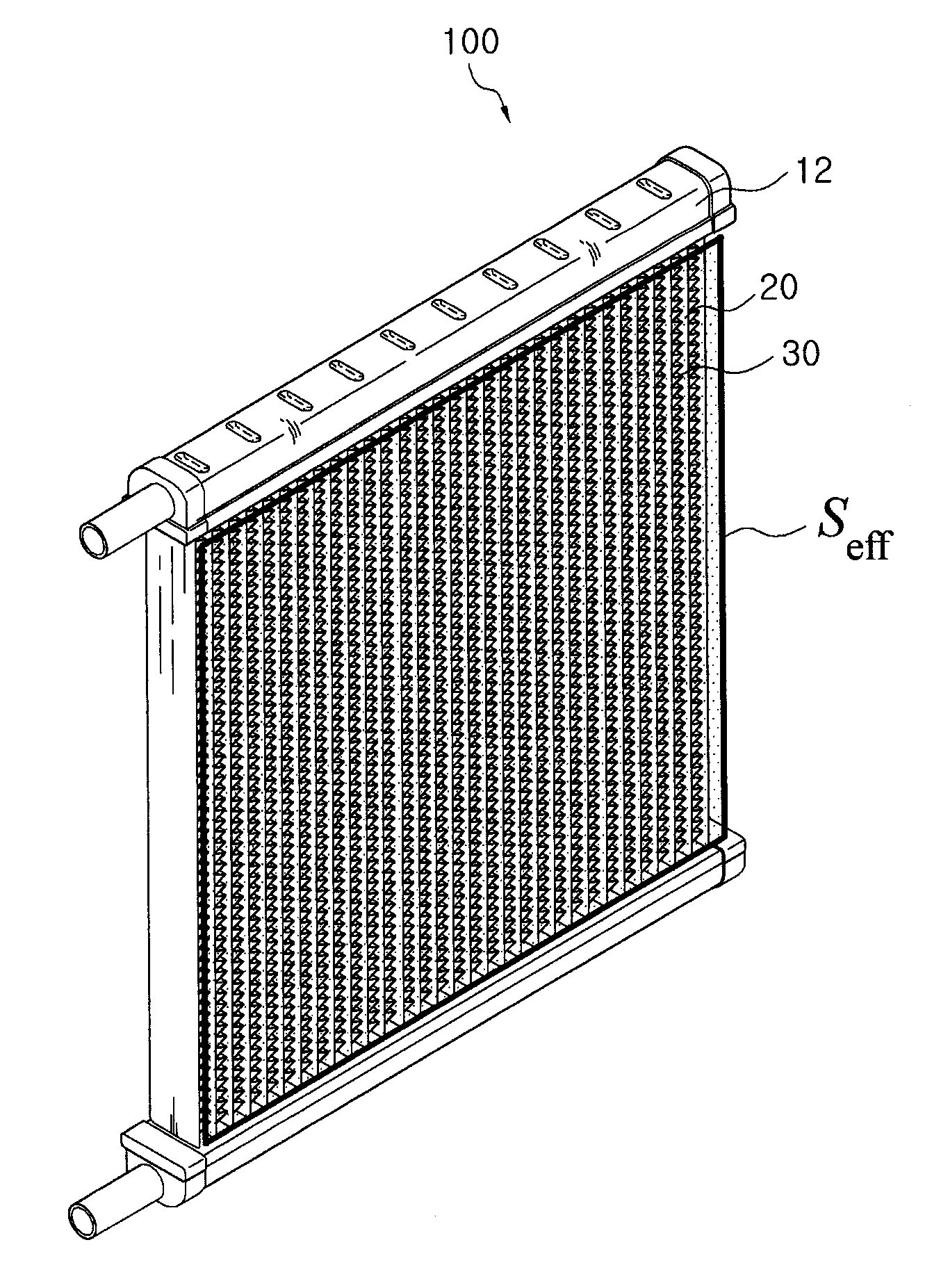

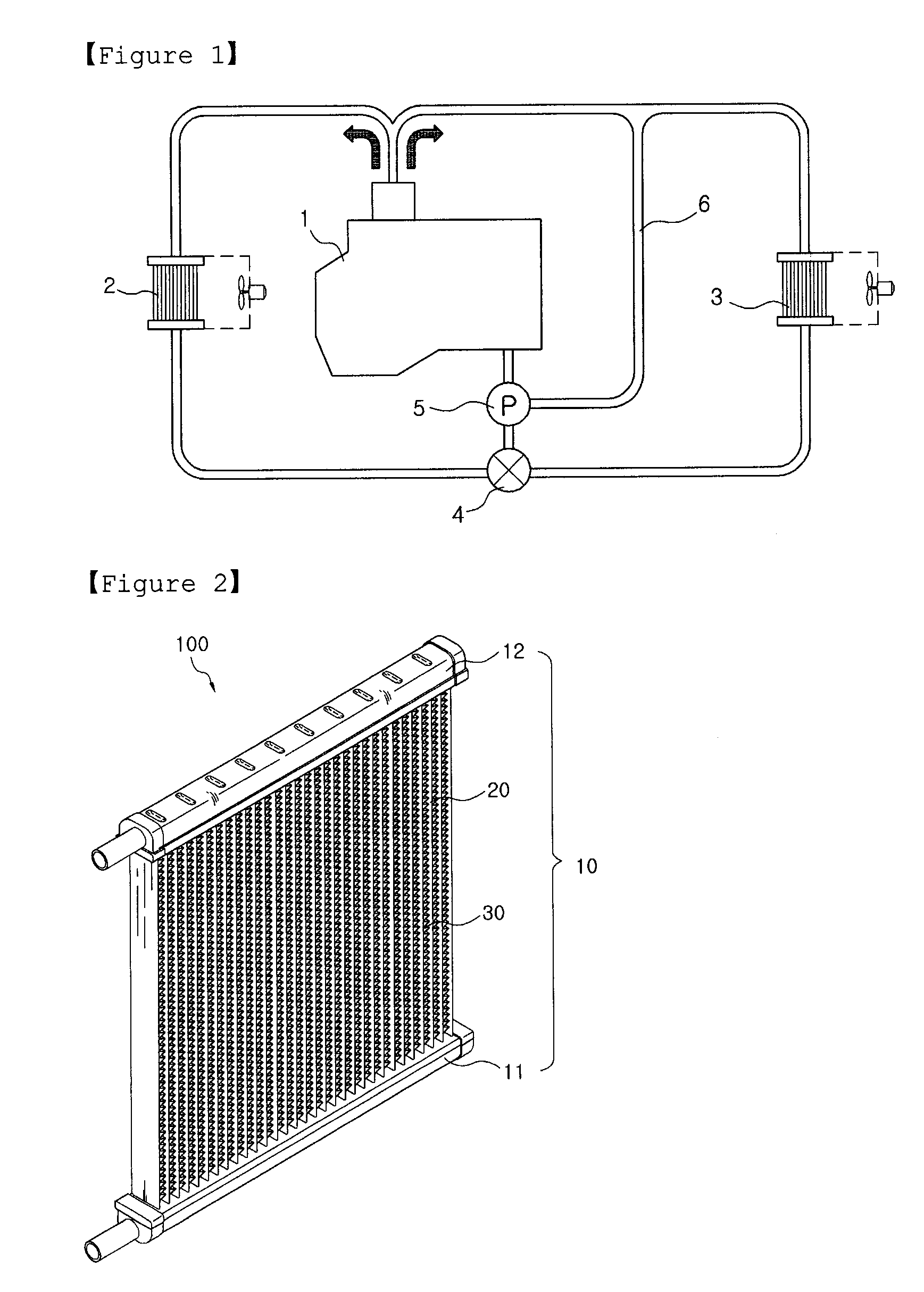

[0023]FIG. 2 is a perspective view of a heat exchanger 100. A heat exchange medium is flown in the heat exchanger 100, and the heat exchanger 100 includes a plurality of tubes 20 which are arranged in parallel at regular distances to be parallel with a ventilation direction, and tanks 10 which are respectively coupled to both ends of the tubes 20. The tanks 10 are divided into an inlet tank 11 in which the heat exchange medium is introduced and then distributed to the plurality of tubes 20 and an outlet tank 12 in which the heat exchange medium moved through the tubes 20 is collected and then discharged. Fins 30 are provided between the tubes 20 so as to increase a contact surface area with air flowing between the tubes 20. As described above, the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com