Malodor counteracting compositions and method for their use

a composition and anti-malodor technology, applied in the field of anti-malodor or anti-moc method, can solve the problem of inability to review all the methods and compositions reported in this contex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 10

Malodor Counteracting (MOC) Compositions and Their Use to Reduce Perception of Malodor

A. Malodor Counteracting Effect of Individual Raw Materials—General Conditions of Evaluation

[0064]A variety of raw materials from Groups (I) and (II) according to the invention were tested, using current sensory analysis methods, for their ability to reduce the perception of malodor of the bathroom, tobacco or kitchen type.

i) Malodor Compositions

[0065]The typical malodor compositions used in these evaluations were composed of the materials indicated hereafter:

Bathroom malodor*Ingredient% w / wDipropylene glycol62.82Thioglycolic acid21.18n-Caproic acid6.00n-Methylmorpholine6.004-Methylphenyl 3-methylbutanoate2.18Skatole0.912-Naphthalenethiol0.91Total100.00*U.S. General Services Administration Federal Supply Service Interim Specification, FA 200-5

[0066]Tobacco Malodor**

[0067]The tobacco malodor was prepared by extraction of cigarette's ash and smoked stub.

[0068]The ash and smoked stub of each cigarette...

examples 1 to 4

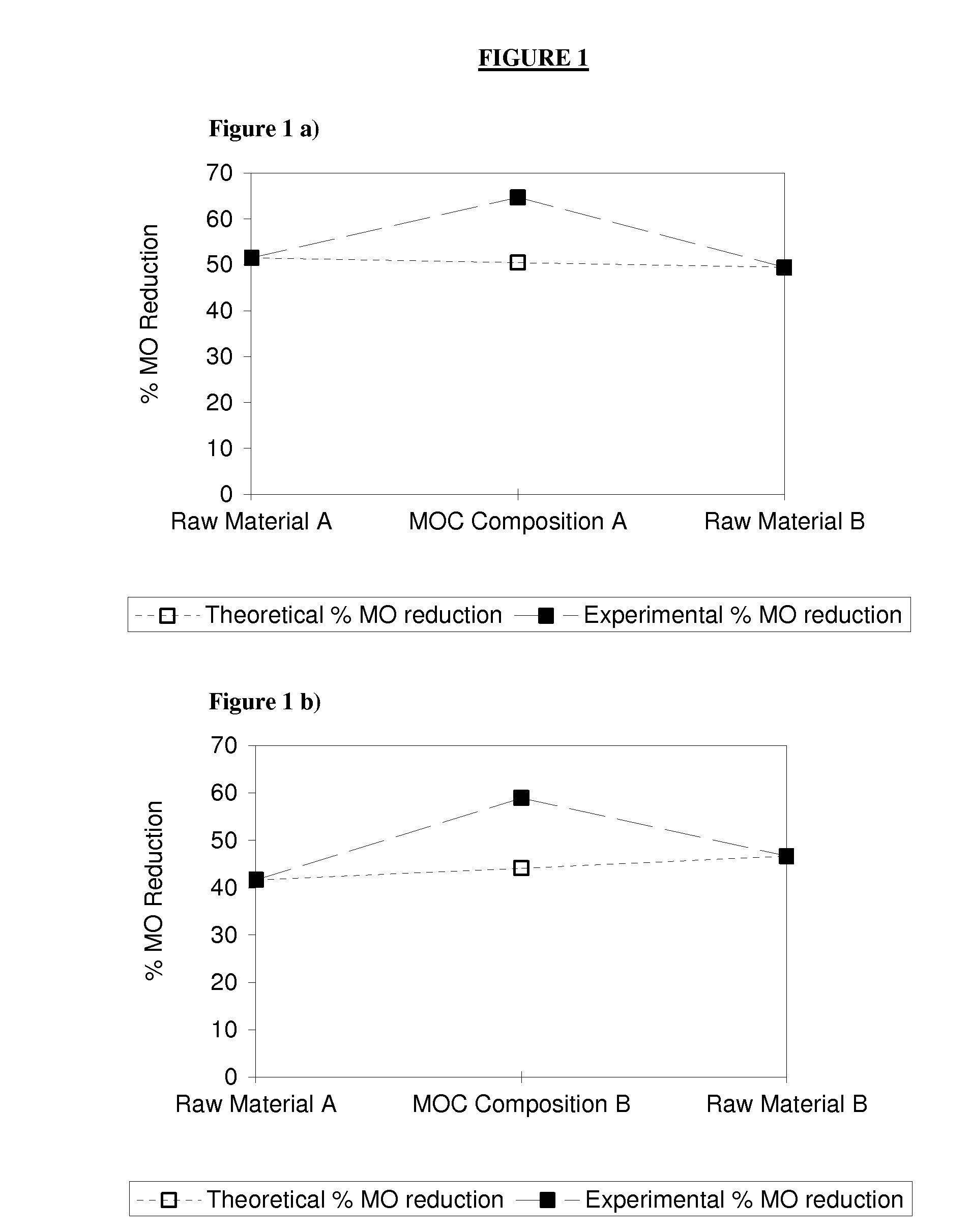

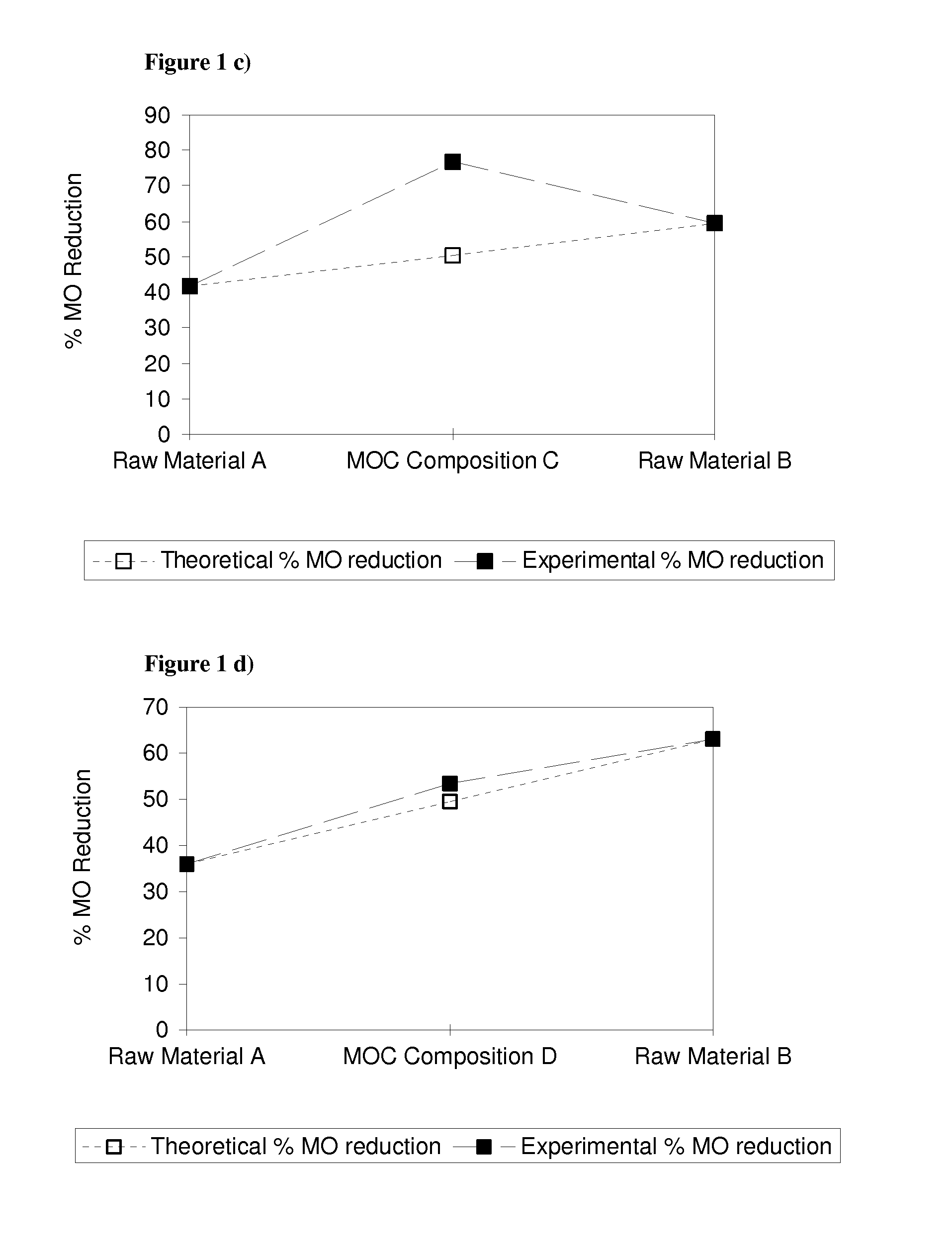

[0099]A variety of MOC compositions A to D were prepared by admixing the corresponding raw materials indicated in Table 3, in a range of relative proportions varying from 1:99 to 99:1 of each of the raw materials indicated.

TABLE 3MOC compositions and their componentsMOC CompositionRaw Material A*Raw Material B*ANitrile described inViolette BC1)U.S. Pat. No. 6,180,814BCitronellyl nitrileKoumalactone2)CCitronellyl nitrileγ-MethyliononeD2-Propyl-1-heptanenitrileα-Damascone1)β-Ionone2)perhydro-3,6-dimethyl-benzo[b]furan-2-one

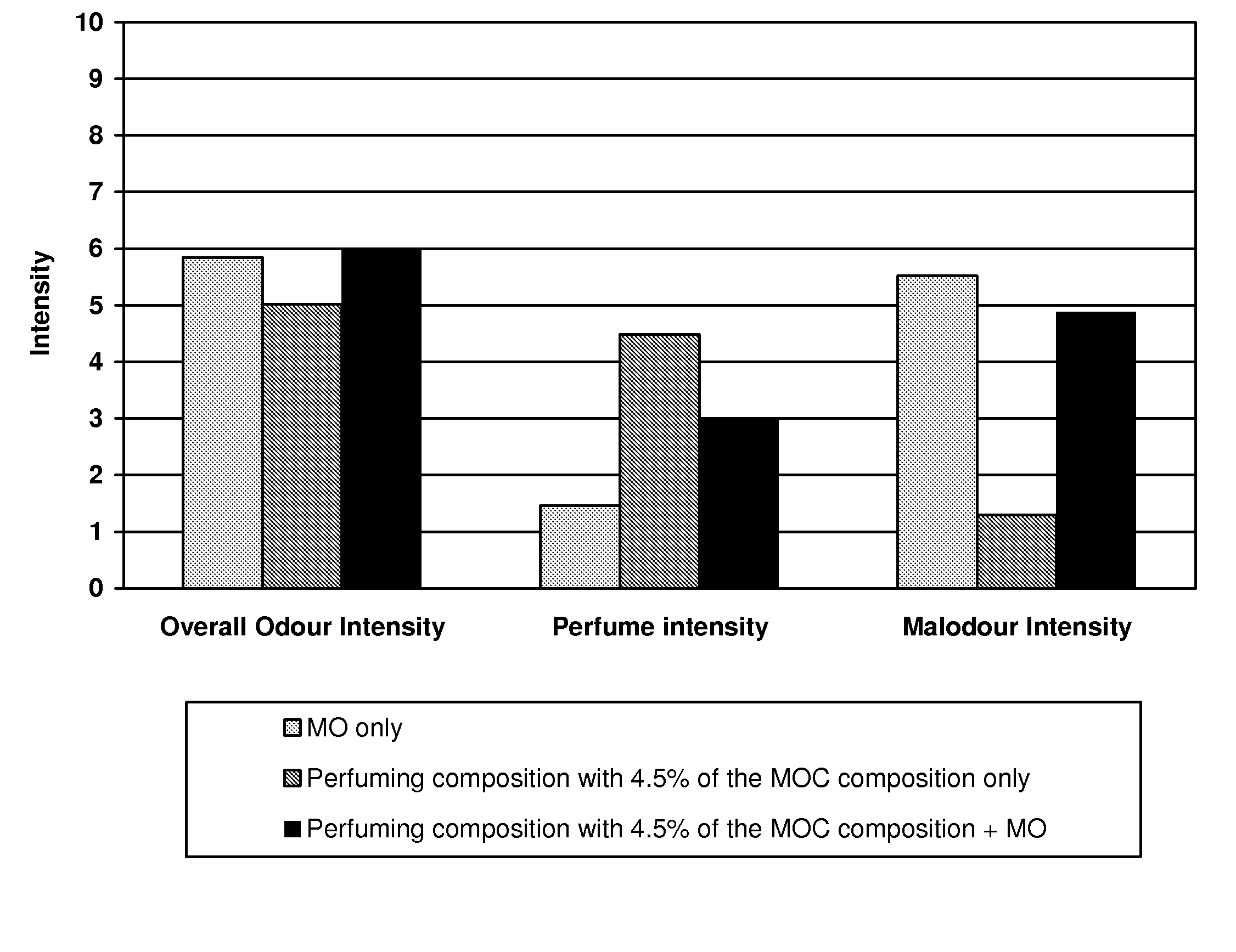

[0100]FIGS. 1a) to d) show the % malodor reduction effectiveness of the MOC compositions A to D against bathroom malodors.

ii) Effect Against Tobacco Malodor

examples 5 to 8

[0101]A variety of MOC compositions E to H were prepared by admixing the corresponding raw materials indicated in Table 4, in a range of relative proportions varying from 1:99 to 99:1 of each of the raw materials indicated.

TABLE 4MOC compositions and their componentsMOC CompositionRaw Material A*Raw Material B*ECitronellyl Nitrile1-(4,66-trimethyl-1,3-cyclohexadien-1-yl)-2-buten-1-oneFCitronellyl Nitrile1-(2,66-trimethyl-1(2)-cyclohexen-1-yl)-1,6-heptadien-3-oneGCitronellyl Nitrileδ-DamasconeHCitronellyl Nitrileγ-Methylionone*Origin: Firmenich SA, Geneva, Switzerland

[0102]FIGS. 2a) to d) show the % malodor reduction effectiveness of the MOC compositions E to H against tobacco malodor.

iii) Effect Against Kitchen Malodor

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

| air diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com