Multi-channel heat exchanger with multi-stage expansion

a heat exchanger and expansion device technology, applied in indirect heat exchangers, lighting and heating apparatuses, refrigeration components, etc., can solve the problems of poor heat exchanger efficiency and lack of efficiency, and achieve the effect of increasing single and multiple pass heat exchanger efficiency and reducing maldistribution of refrigeran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

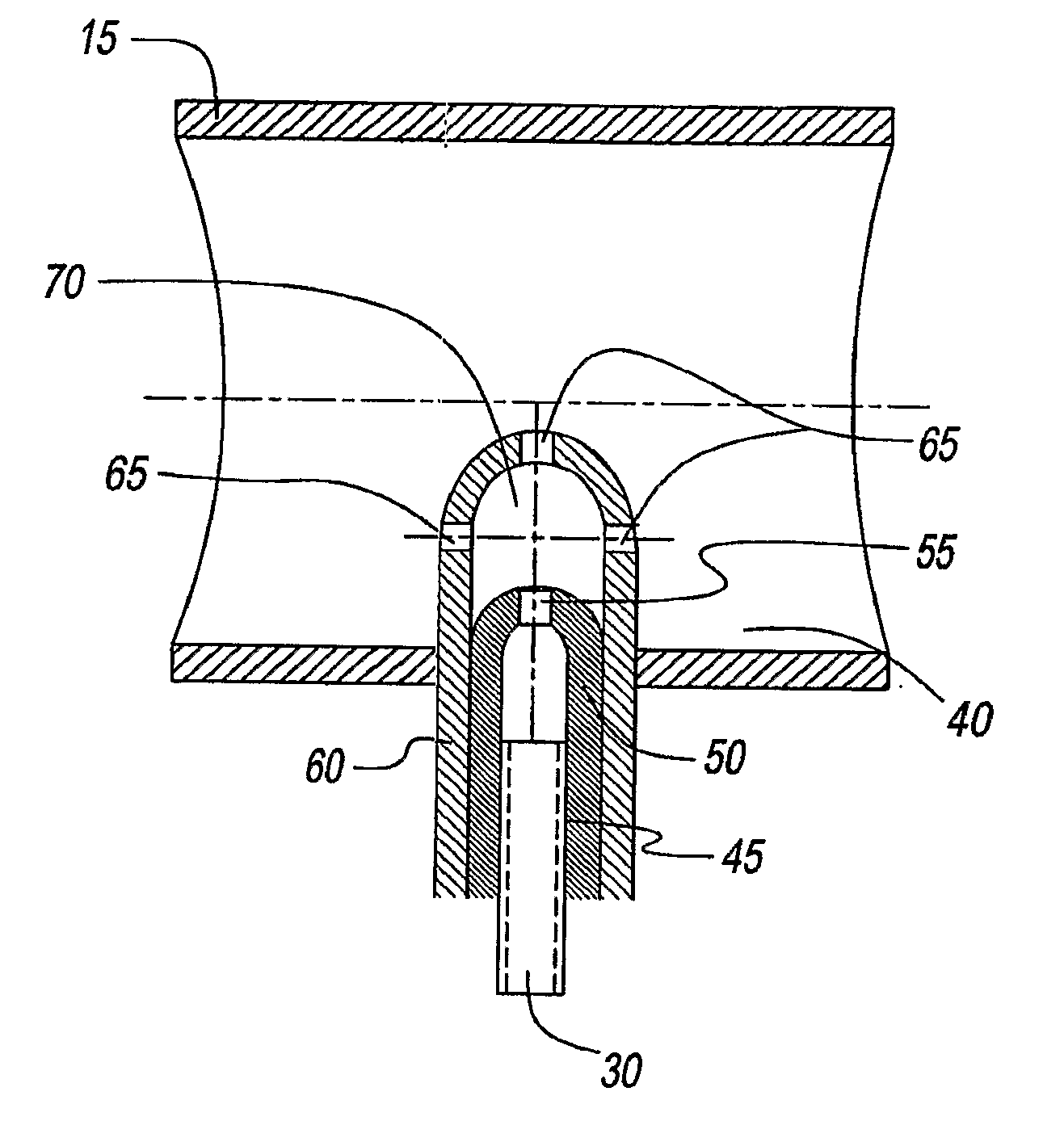

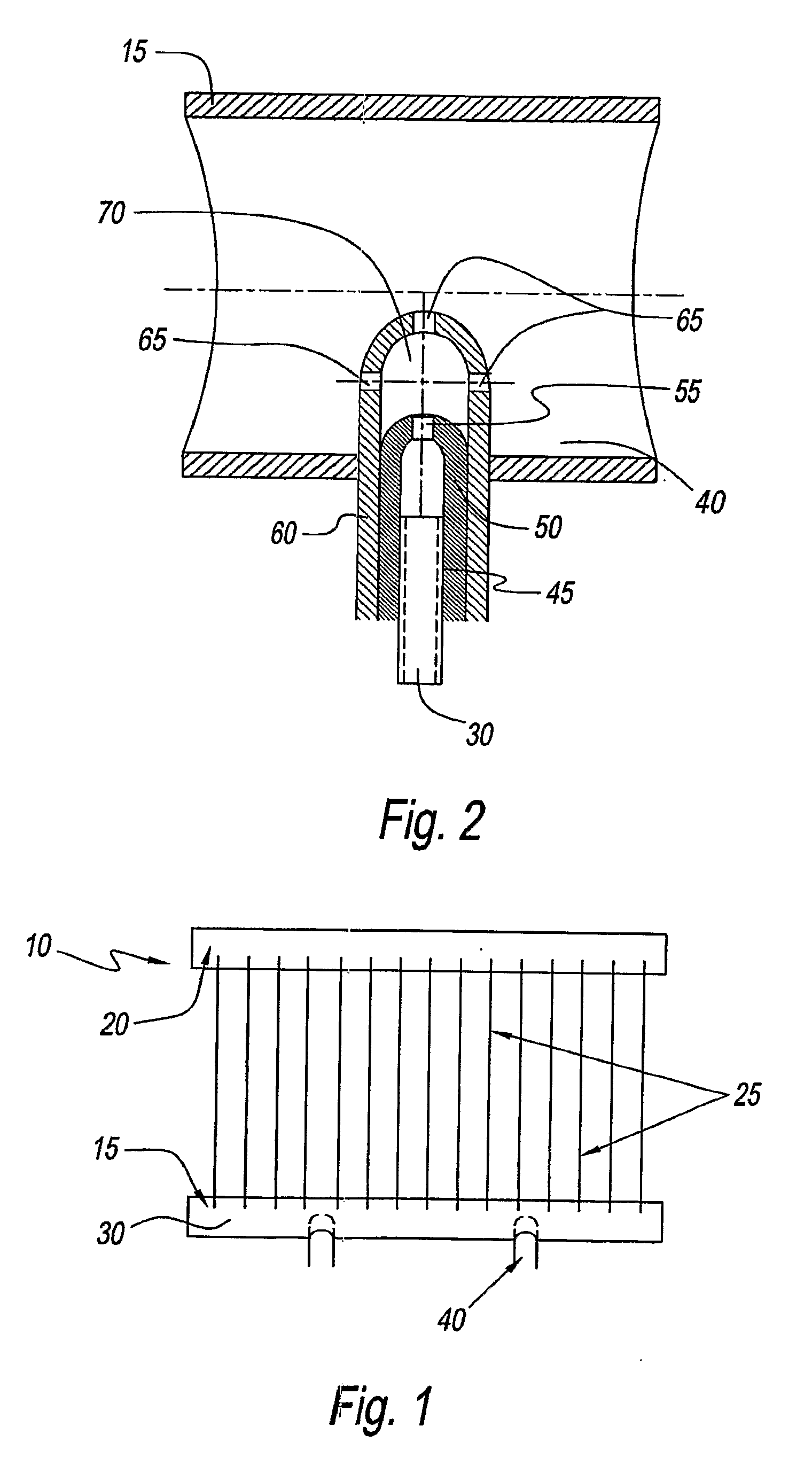

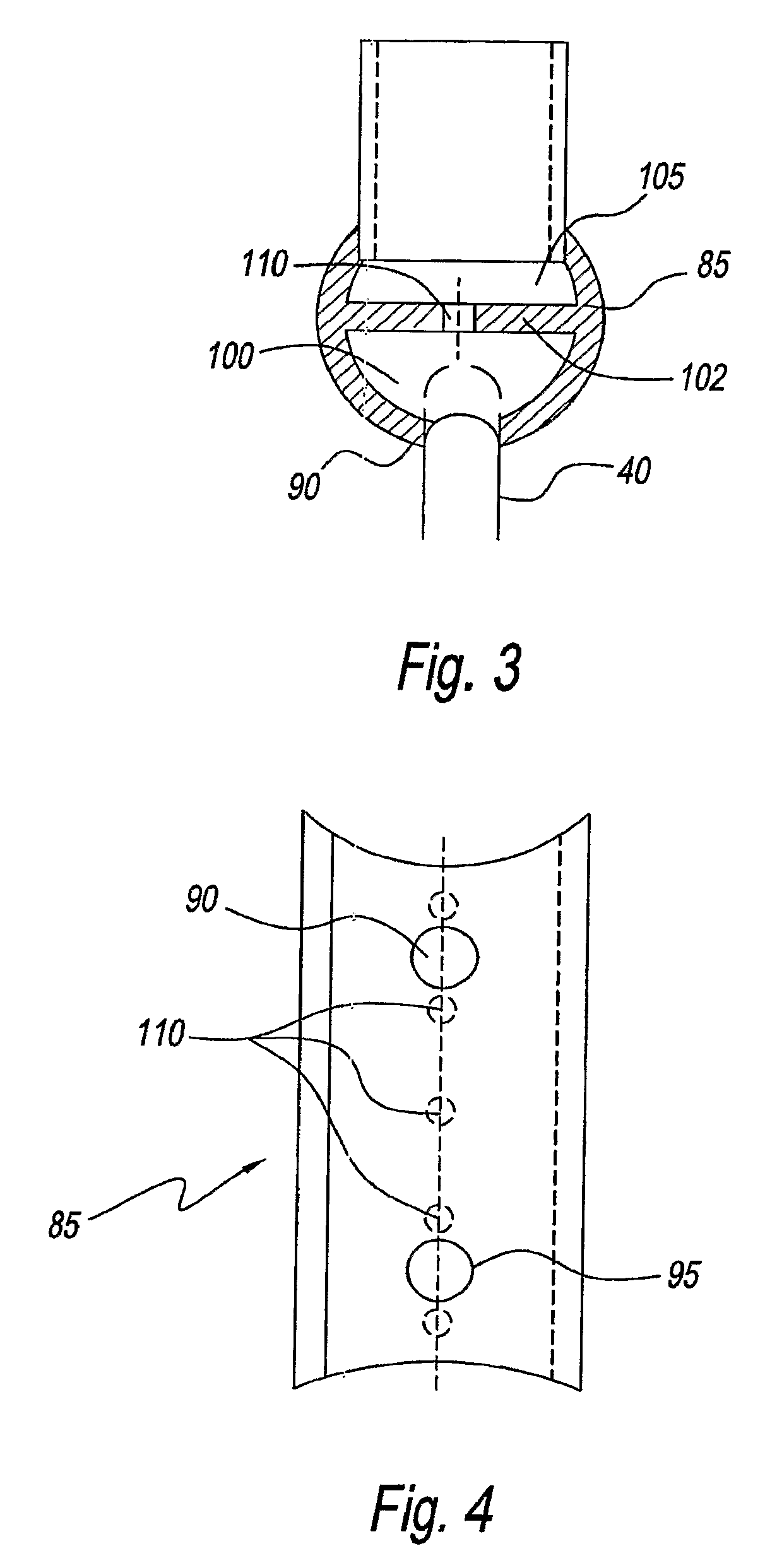

[0022]FIG. 1 illustrates a mini-channel heat exchanger generally represented by reference numeral 10. Heat exchanger 10 has an inlet manifold 15 and an outlet manifold 20. Connecting manifolds 15 and 20 are a series or plurality of mini- or micro-channel tubes 25 that form the main body of heat exchanger 10. Each mini- or micro-channel tube 25 is a very narrow tube that with other tubes form the main body of the heat exchanger 10 and transport refrigerant 30 during evaporation.

[0023]Inlet manifold 15 receives a refrigerant 30 that can be either a single or a two-phase refrigerant that flows through mini- or micro-channel tubes 25. Inlet manifold receives multi-expansion device 40 of the present invention. At least one or more multi-expansion devices 40 of the present invention can be inserted into manifold 15 to enhance pressure drop of refrigerant 30 to ensure an even distribution of refrigerant for mini-channel tubes 25. While FIG. 1 shows a single-pass configuration of a heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com