Hinged Partition and Arrangement for Closing Off a Room Against a Fluid Flowing into the Room or Out of the Room

a technology for closing off a room and a fluid, applied in the direction of hinges, door/window fittings, building components, etc., can solve the problems of inability to ensure sealing function or insufficiently reduced extent, expensive alignment of the axis or etc., to achieve the effect of reducing the total weight of the hinged partition, reducing the thickness of the barrier, and increasing the lifting for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

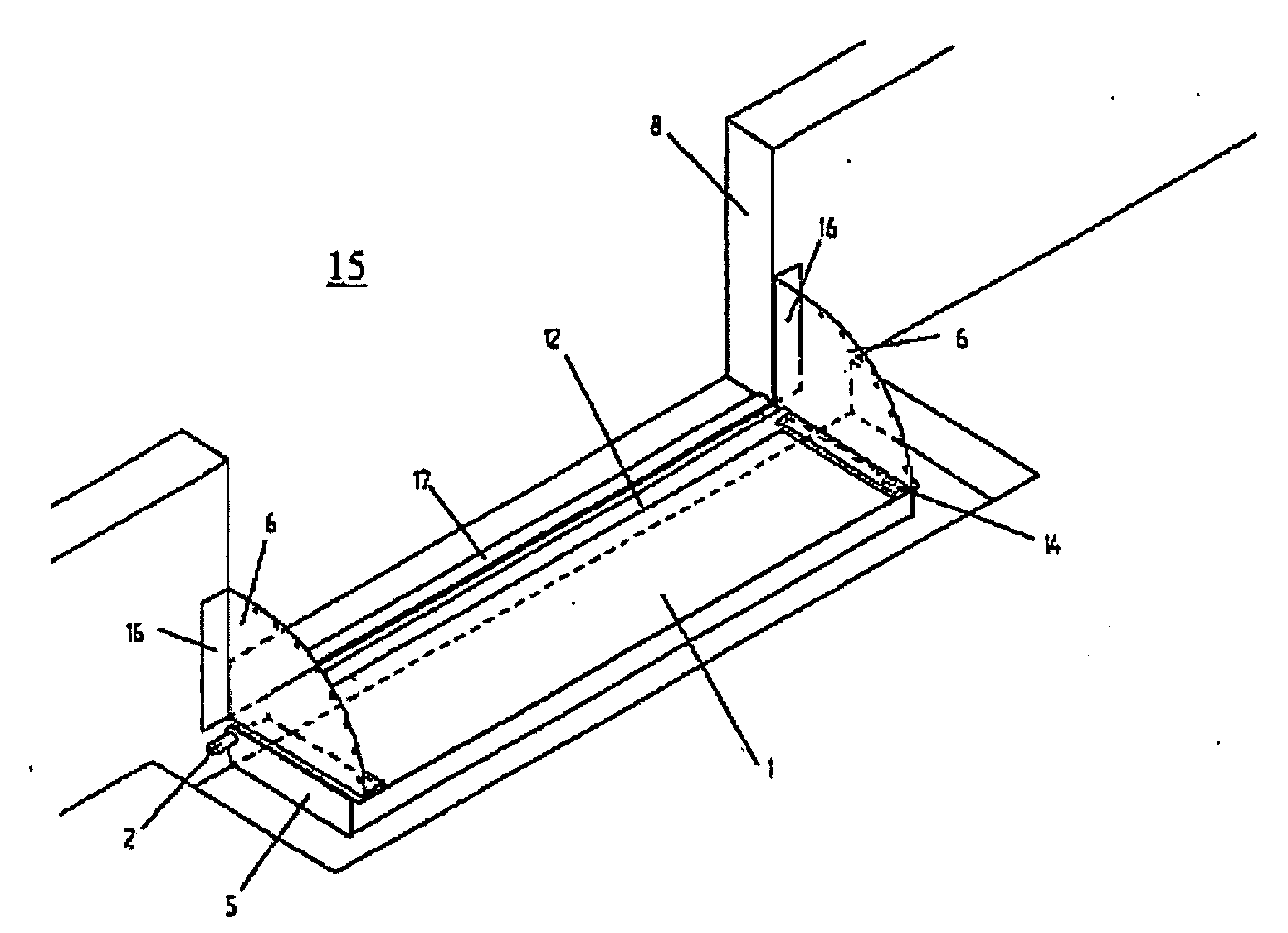

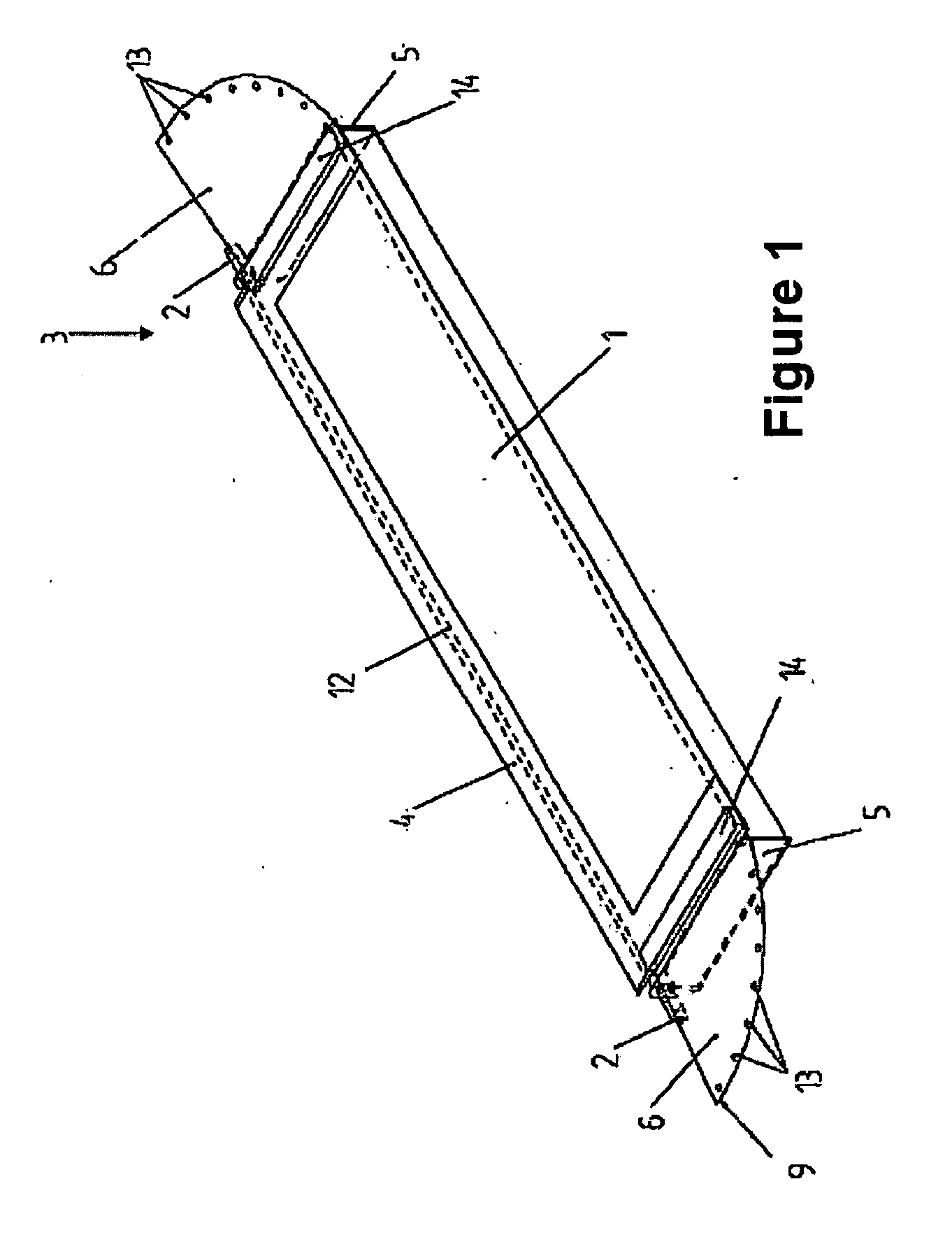

[0058]FIG. 1 shows a perspective view of a practical example of a hinged partition 1 of an arrangement for closing off a room against a fluid flowing into the room or out from the room, especially a combustible fluid. The hinged partition 1 is formed by a prismatic body in this representation, which can be sunk into a recess of a floor, the recess not being shown. The hinged partition 1 can be pivoted around an axis 2 from a first position into a second position. For example, the hinged partition 1 can have a metallic surface. It can be formed by a box made of metal in which a core is arranged that can be, for example, made of a plastic or similar material. A flame-retardant layer may be arranged between the core and the outer mantle.

[0059]In the practical example shown, the hinged partition 1 is connected to a seal 3. The seal 3 can be made of one or several parts. The seal 3 is designed in a sheet-like manner. Preferably it is made of polytetrafluoroethylene.

[0060]Next to the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com