Fin, thermal module, and method for assembling the same

a cooling fin and thermal module technology, applied in the direction of tubular elements, metal-working apparatus, lighting and heating apparatus, etc., can solve the problems of high heat flux of heat dissipation, waste of solder paste b>74/b>, and additional labor, so as to improve the prior art and improve the quality of soldering and heat transfer performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]This invention provides a cooling fin, a thermal module including the cooling fin, and a method for assembling the thermal module.

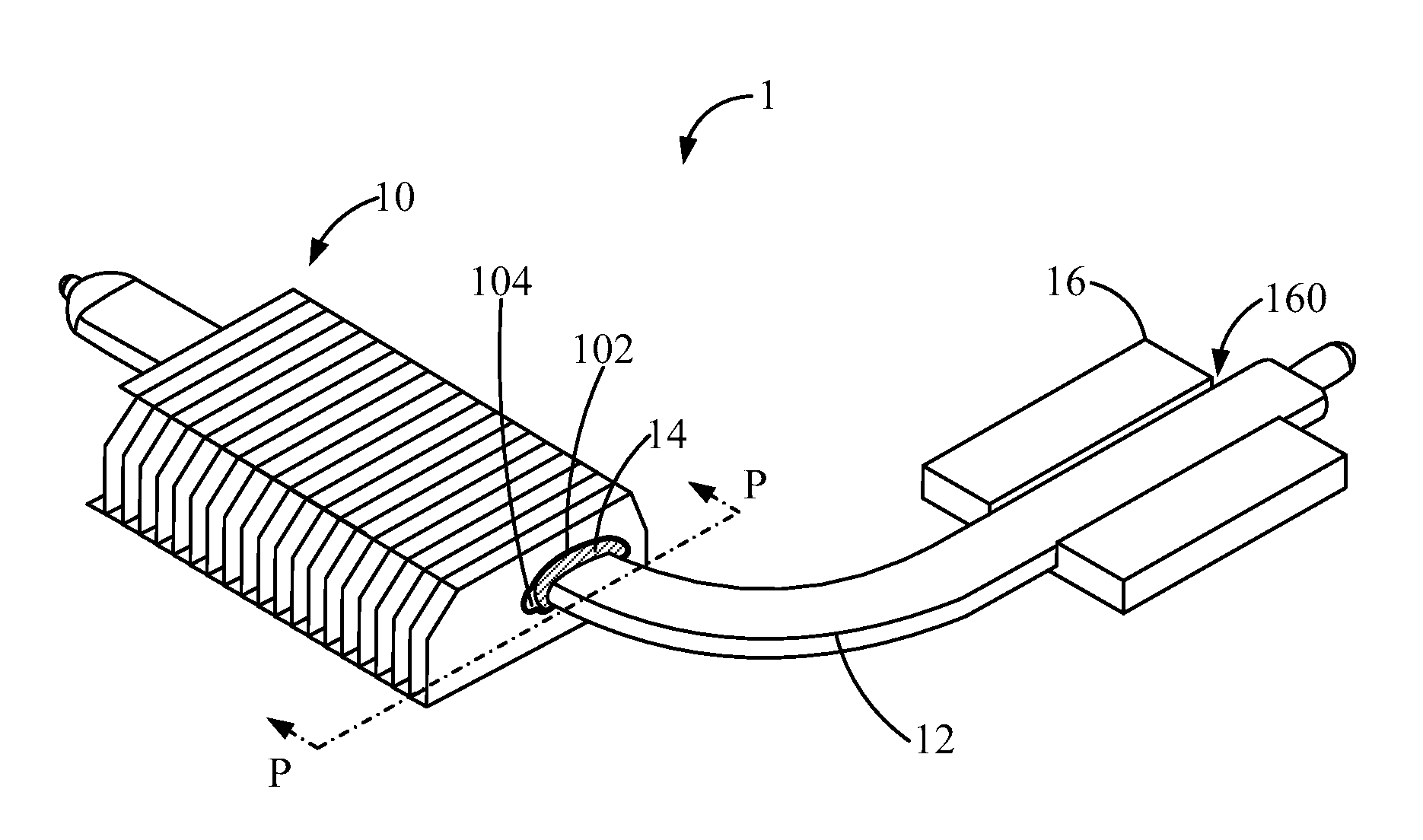

[0030]According to one embodiment of the invention, the cooling fin can be combined with a heat pipe and a joint material, thus to form the thermal module. FIGS. 3A to 3B are schematic diagrams showing a fin according to one embodiment of the invention. Please refer to FIGS. 3A to 3C.

[0031]In FIGS. 3A to 3C, a main body 100 of a cooling fin 10 is flat, and the main body 100 has a through hole 102 and an feeding hole 104. The through hole 102 can be used for the heat pipe (not shown) to pass through. The feeding hole 104 communicates with the through hole 102. When the cooling fin 10 is combined with the heat pipe, the feeding hole 104 is above the through hole 102, and the joint material (not shown) is injected into the feeding hole 104 to fill a clearance between the heat pipe and the inner wall of the through hole 102. In addition, the through hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com