Jewelry assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

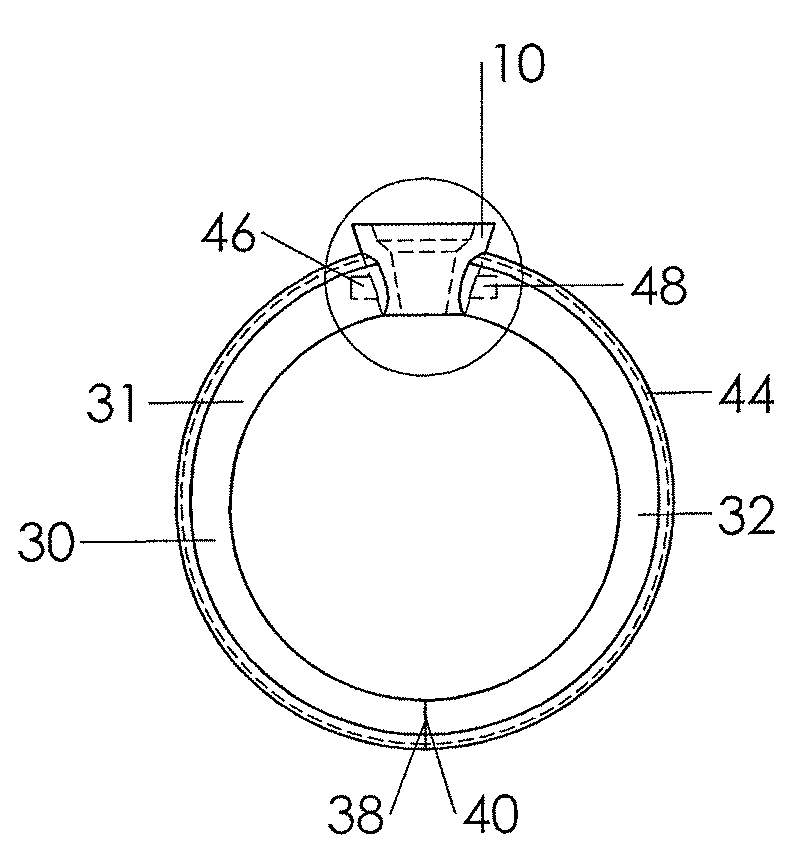

[0122]In the following description, examples and embodiments will be described assuming that each of the components is in the orientation as it would be in a ring assembly which is orientated such that a collet is at the top of a shank. However, this is done for facility of description only, the relations between the components being equivalent in any other orientation.

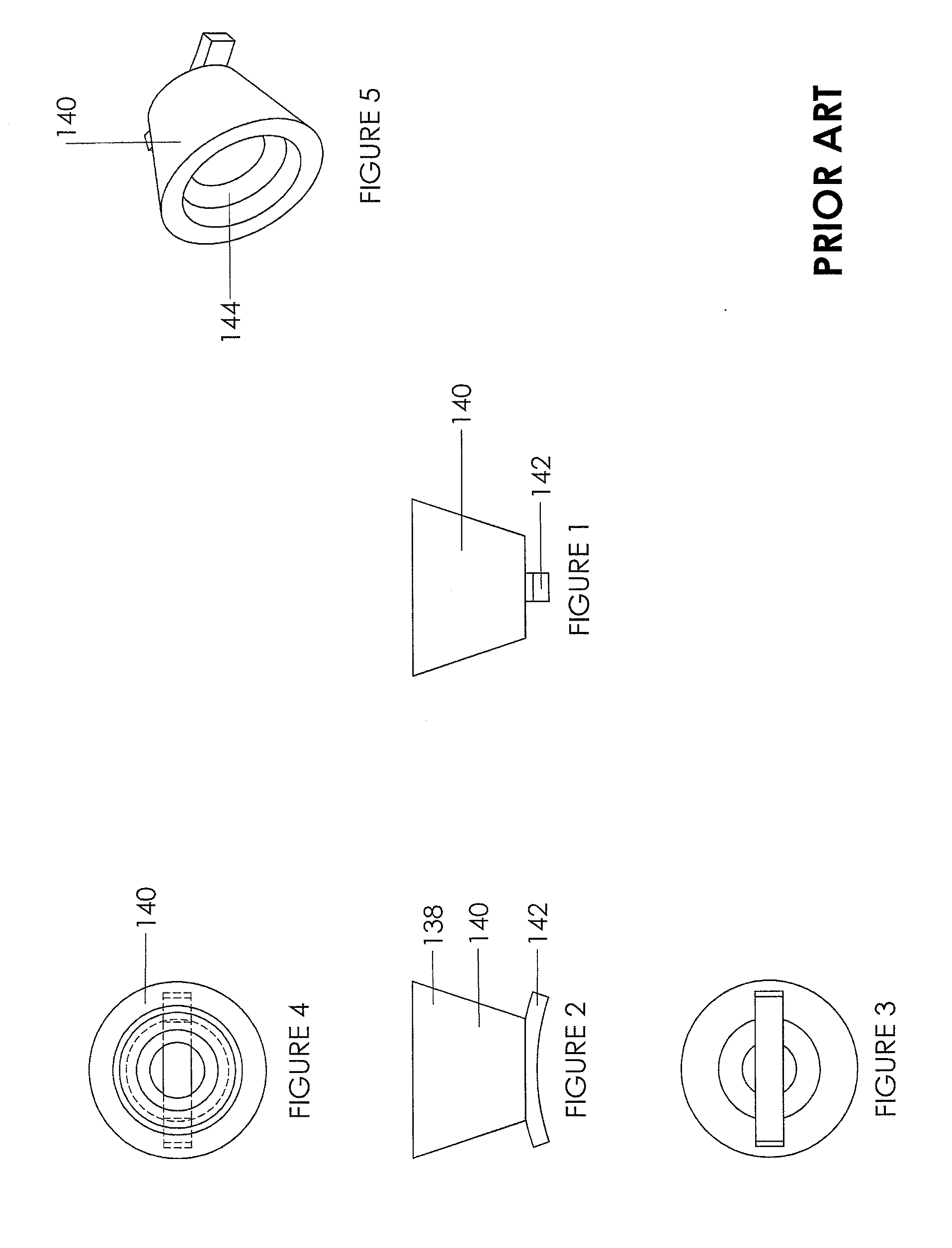

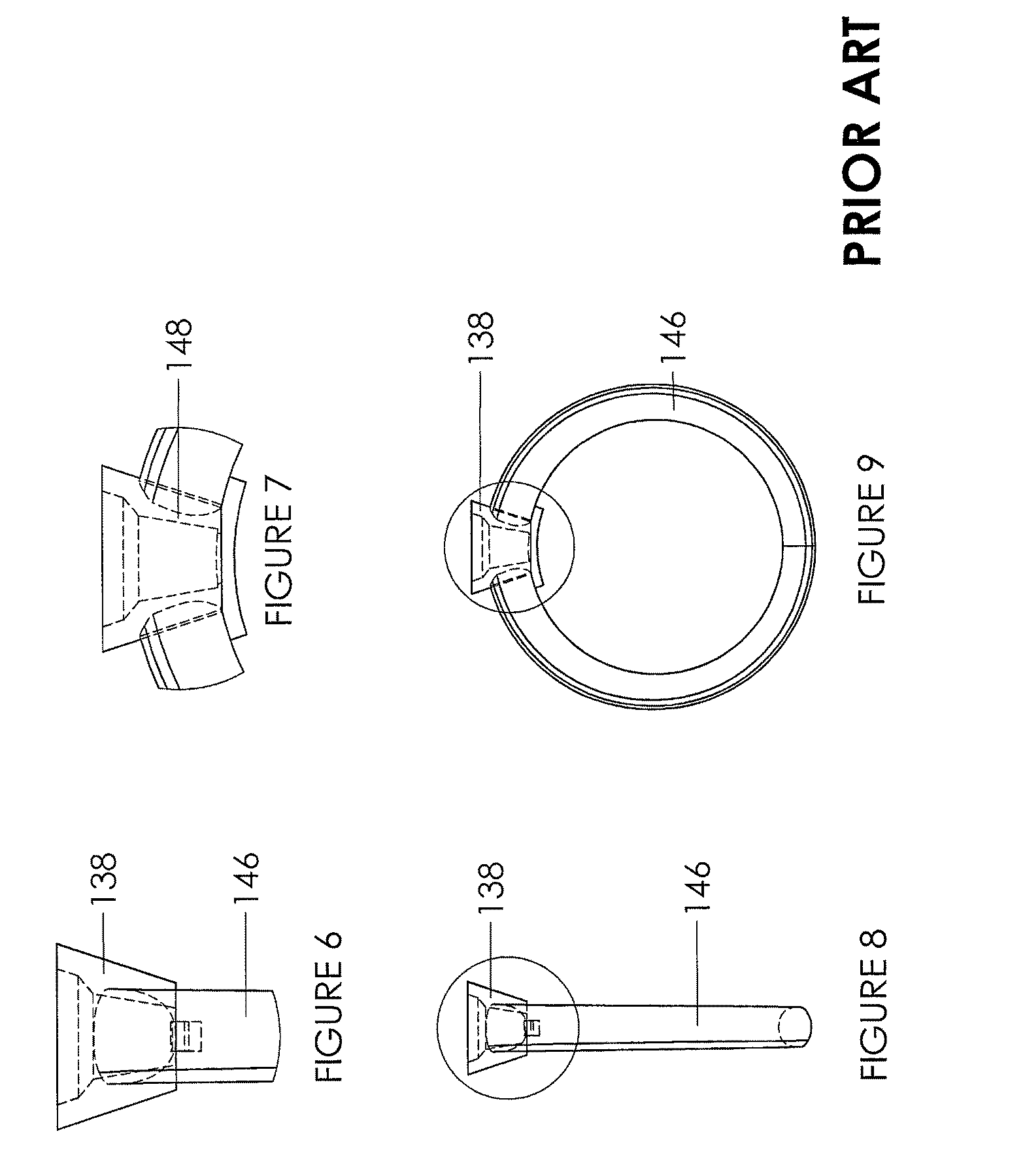

[0123]FIGS. 1 to 9 depict a prior art arrangement example, in which FIGS. 1 to 5 depict a collet 138 and FIGS. 6 to 9 depict a ring assembly incorporating the collet 138 according to FIGS. 1 to 5.

[0124]The collet 138 comprises a substantially frusto-conical body 140 and a support bar 142. The collet body 140 is provided with a displaced internal shelf 144 for accepting a jewel stone or precious metal. The support bar 142 substantially follows the arc of a circle and is formed below the base of the collet 138.

[0125]The shank 146 is a substantially annular member provided with a gap 148 in which the collet 138 can sit s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com