Active gauge protection for drill bits

a drill bit and active technology, applied in the field of drill bits, can solve the problems of severely damaging the cutting elements of the drill bit, the drill bit may begin to move off-center from the center of the borehole, and the drill bit may begin to move off-center, so as to minimize the damage to the gauge cutter and minimize the gouging of the casing wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

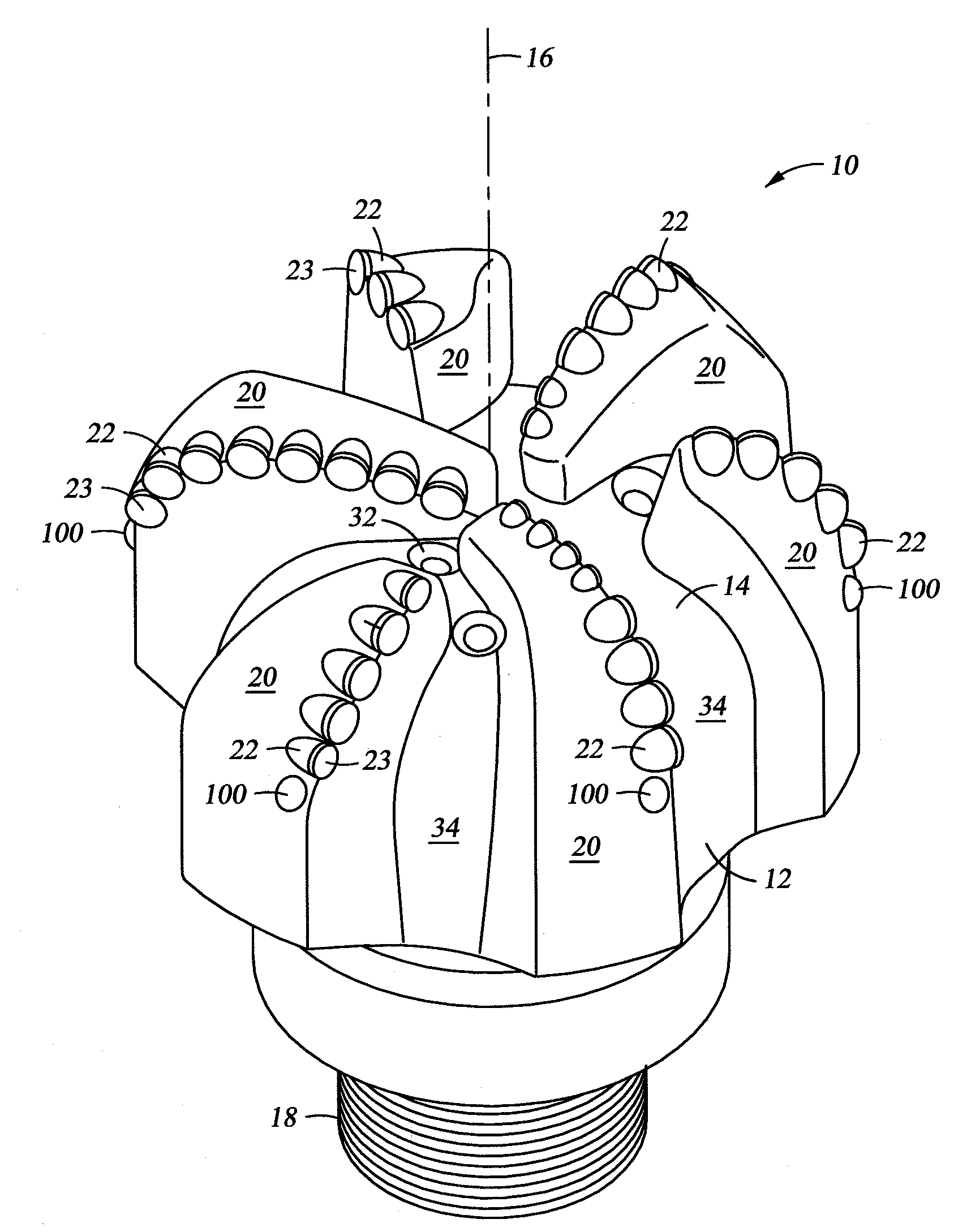

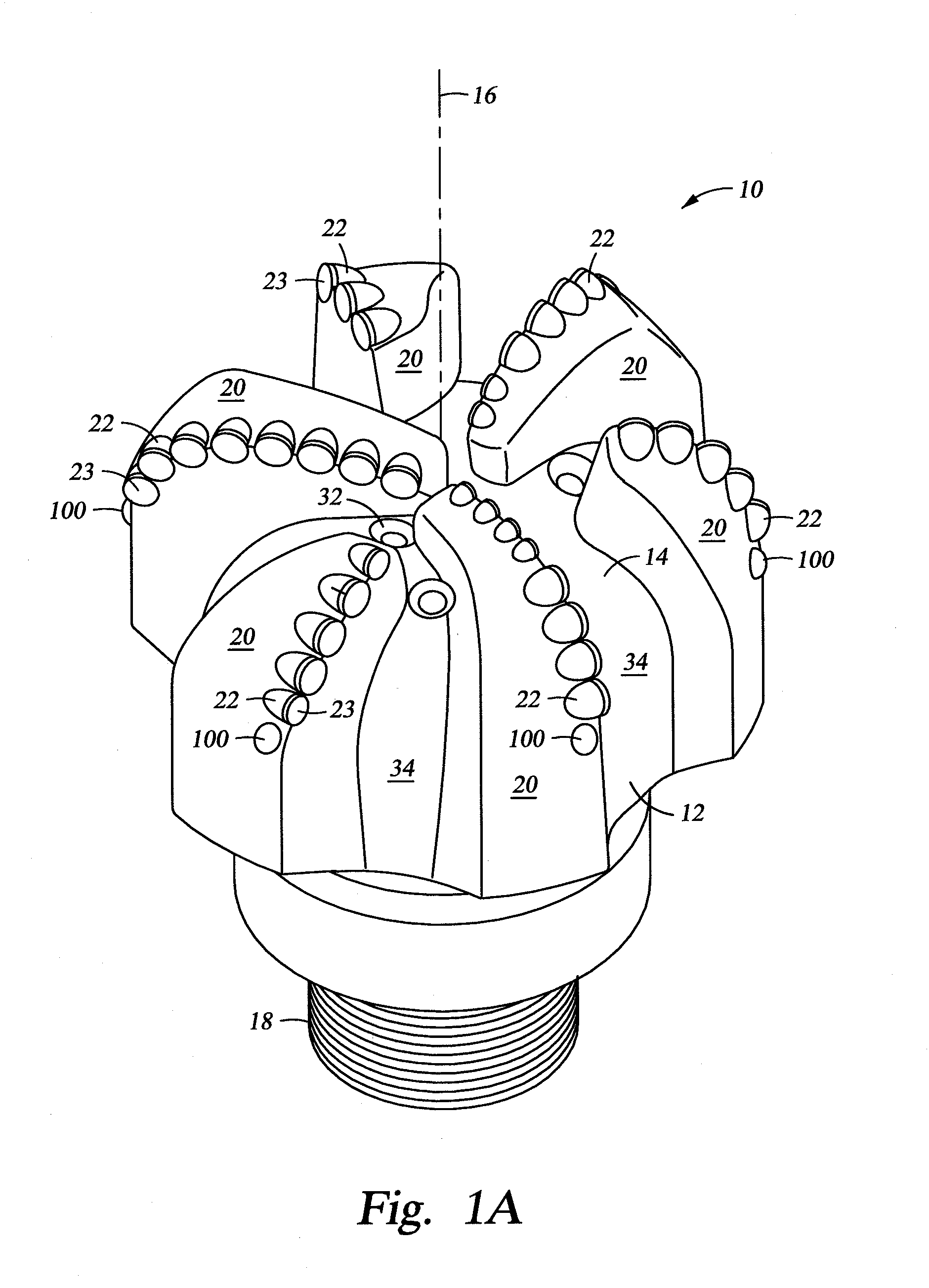

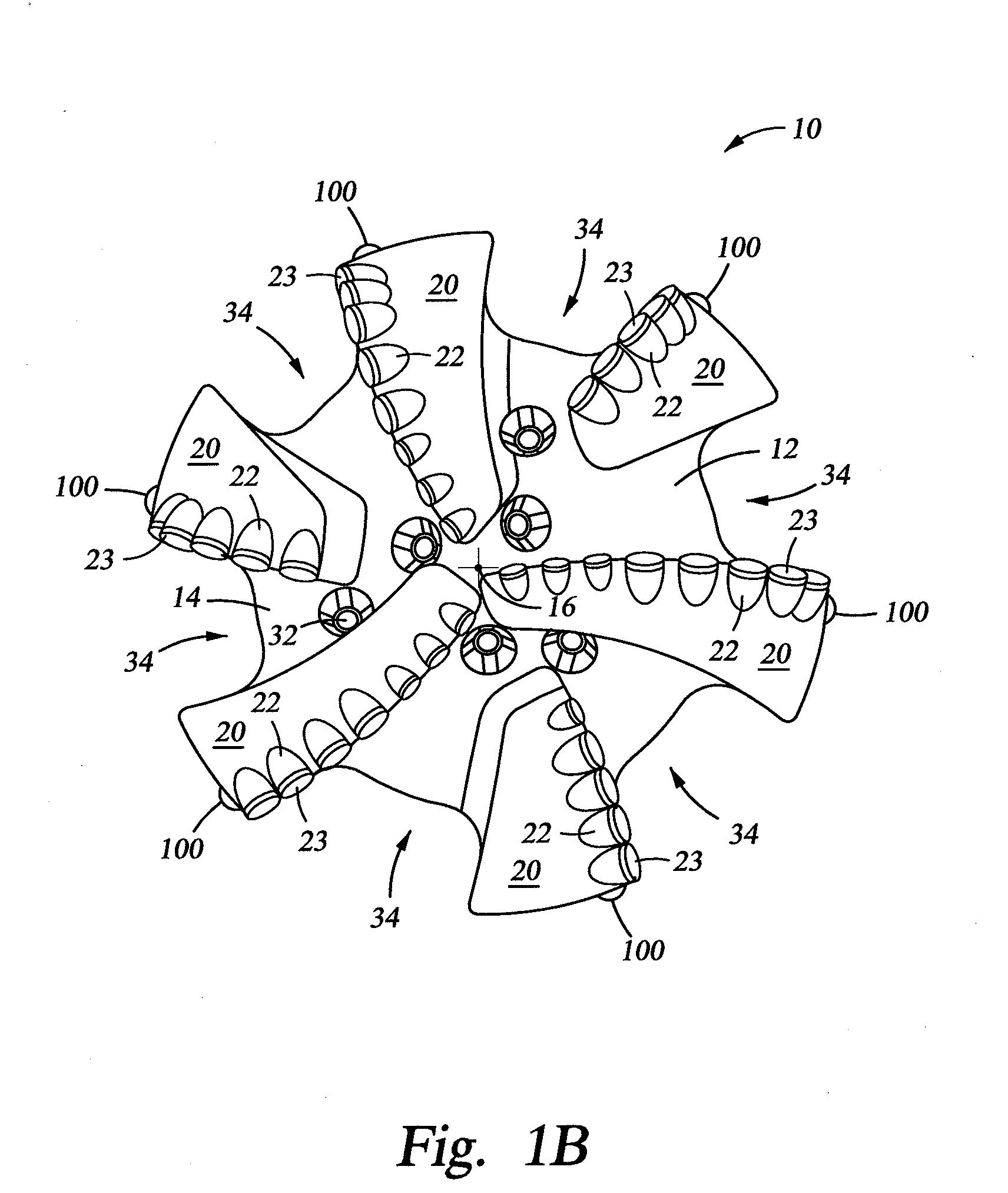

[0014]Refer now to the drawings wherein depicted elements are not necessarily shown to scale and wherein like or similar elements are designated by the same reference numeral through the several views.

[0015]As used herein, the terms “up” and “down”; “upper” and “lower”; “uphole” and “downhole” and other like terms indicating relative positions to a given point or element are utilized to more clearly describe some elements of the embodiments of the invention. Commonly, these terms relate to a reference point as the surface from which drilling operations are initiated as being the top point and the total depth of the well being the lowest point.

[0016]An apparatus and method to protect the cutting elements of a drill bit, specifically the gauge cutters, from coming into contact with the borehole casing during both traversal down the hole and during drill out operations are disclosed. The drill bit comprises one or more protective inserts that protrude beyond the gauge distance and into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com