Lubricating Composition Containing Sulphur, Phosphorus and Ashfree Antiwear Agent and Amine Containing Friction Modifier

a technology of phosphorus and sulphur, which is applied in the direction of lubricant compositions, organic chemistry, fuels, etc., can solve the problems of reducing the performance of said catalysts, zddp is believed to have a detrimental impact on fuel economy and efficiency, and interferes with each other's respective functions, so as to reduce or prevent phosphorus emissions, reduce or prevent sulphur emissions, and improve fuel economy

Inactive Publication Date: 2010-04-15

THE LUBRIZOL CORP

View PDF3 Cites 54 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0029]In one embodiment the invention provides for the use of a lubricating composition as disclosed herein for providing at least one of (i) reducing or preventing phosphorus emissions, (ii) reducing or preventing sulphur emissions, (ii) wholly or partially replacing ZDDP in lubricating oils, (iii) improving fuel economy, (iv) fuel economy retention / efficiency, and (v) lead and copper corrosion resistance.

Problems solved by technology

ZDDP is also believed to have a detrimental impact on fuel economy and efficiency.

Both ZDDP and friction modifier function by adsorption on sliding surfaces, and each may interfere with each other's respective functions.

In addition, sulphur and phosphorus tend to poison the catalysts used in catalytic converters, resulting in a reduction in performance of said catalysts.

However, reducing the levels of antiwear additives such as ZDDP, is likely to increase wear and result in other detrimental performance of an engine.

Whilst the presence of ZDDP reduces wear, and reduced amounts of ZDDP reduce emissions, engines experience corrosion.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

Ex1

[0114]A lubricating composition is prepared containing 0.2 wt % of di-2-ethylhexyl tartrate, 0.2 wt % of hydroxyalkyl amine (Ethomeen T / 12), 0.86 wt % of other antiwear agents (including zinc dialkdithiophosphate), 5 wt % of dispersants, 1.5 wt % of detergents, 1.3 wt % of antioxidants, 4.3 wt % of viscosity modifier. The lubricating composition has a phosphorus content of about 760 ppm, and a sulphur content of 0.25 wt %.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a lubricating composition containing an oil of lubricating viscosity, an amine-containing friction modifier, and an ashless antiwear agent. The lubricating composition is suitable for lubricating an internal combustion engine.

Description

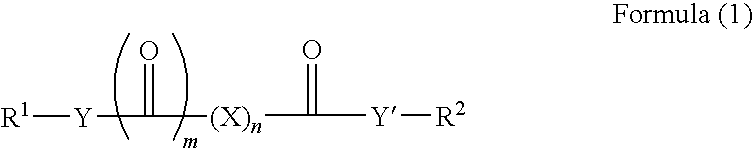

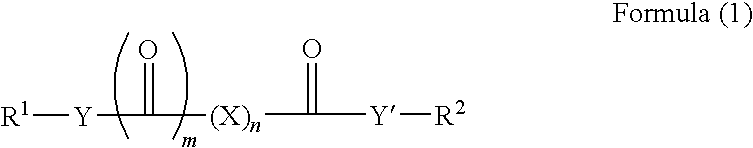

FIELD OF INVENTION[0001]The invention provides a lubricating composition containing an oil of lubricating viscosity, an amine-containing friction modifier, and an ashless antiwear agent. The lubricating composition is suitable for lubricating an internal combustion engine.BACKGROUND OF THE INVENTION[0002]Engine manufacturers have focused on improving engine design in order to improve fuel economy and efficiency (typically, based on Federal Corporate Average Fuel Economy (CAFE) standards). Whilst improvements in engine design and operation have contributed, improved formulation of engine oil lubricant may also improve fuel economy and efficiency. Lubricants function to reduce and disperse engine deposits which accumulate when the engines are running. They also serve to reduce the friction between sliding moving parts (typically metallic or ceramic) that are in contact.[0003]It is well known for lubricating oils to contain a number of additives used to protect the mechanical devices s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): C10M169/00C10M129/34C10M129/36C10M129/72C10M133/16

CPCC10M141/06C10M2207/028C10N2240/10C10M2207/262C10M2207/282C10M2207/288C10M2207/289C10M2215/04C10M2215/042C10M2215/08C10M2215/082C10M2215/086C10M2215/28C10M2219/046C10M2223/045C10N2230/02C10N2230/06C10N2230/12C10N2230/42C10N2230/43C10N2230/45C10N2230/54C10N2210/02C10N2030/02C10N2030/06C10N2030/12C10N2040/25C10N2030/42C10N2030/43C10N2030/45C10N2030/54C10N2010/04

Inventor KOCSIS, JODYMOSIER, PATRICK E.

Owner THE LUBRIZOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com