Molded polymeric drip edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

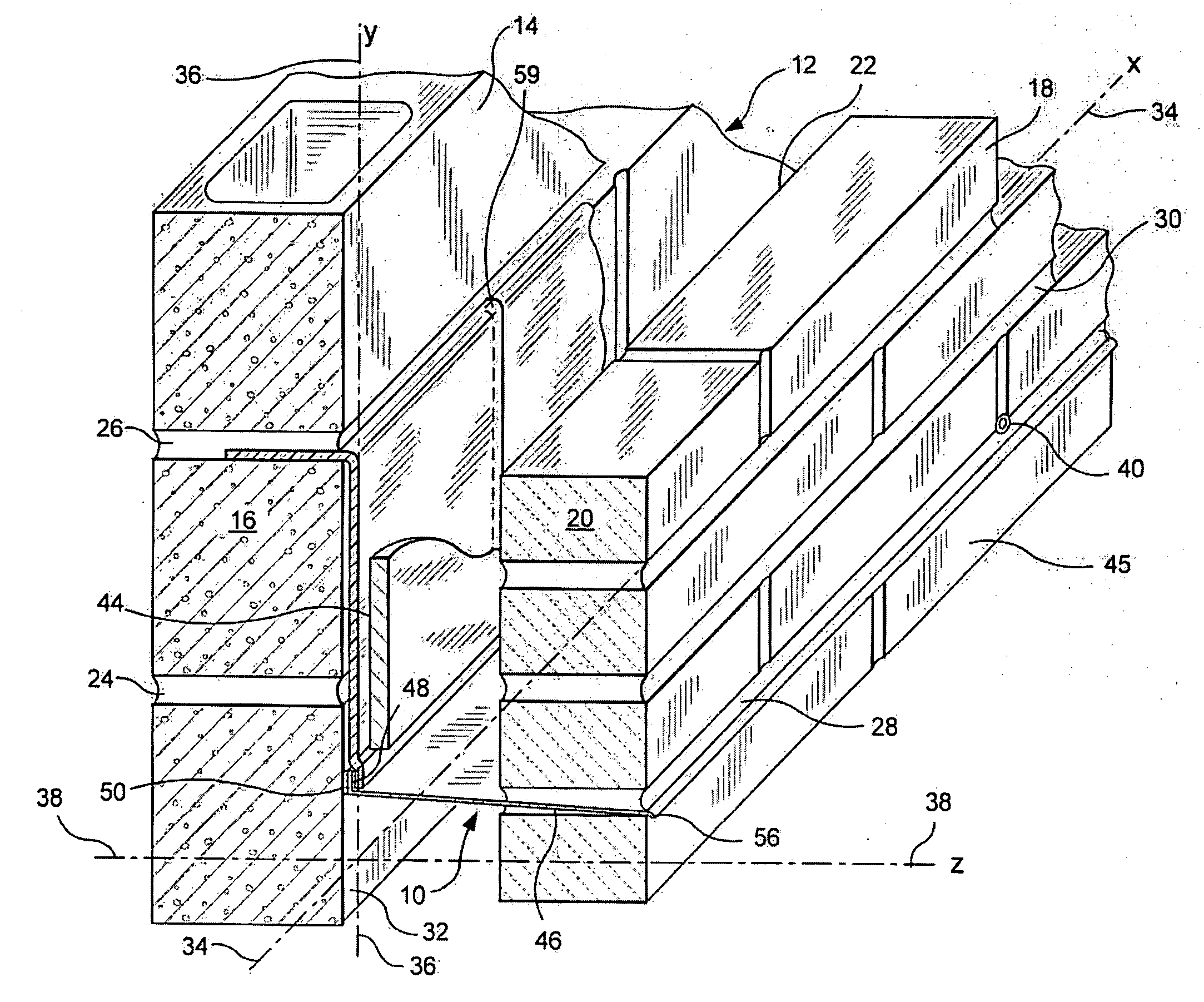

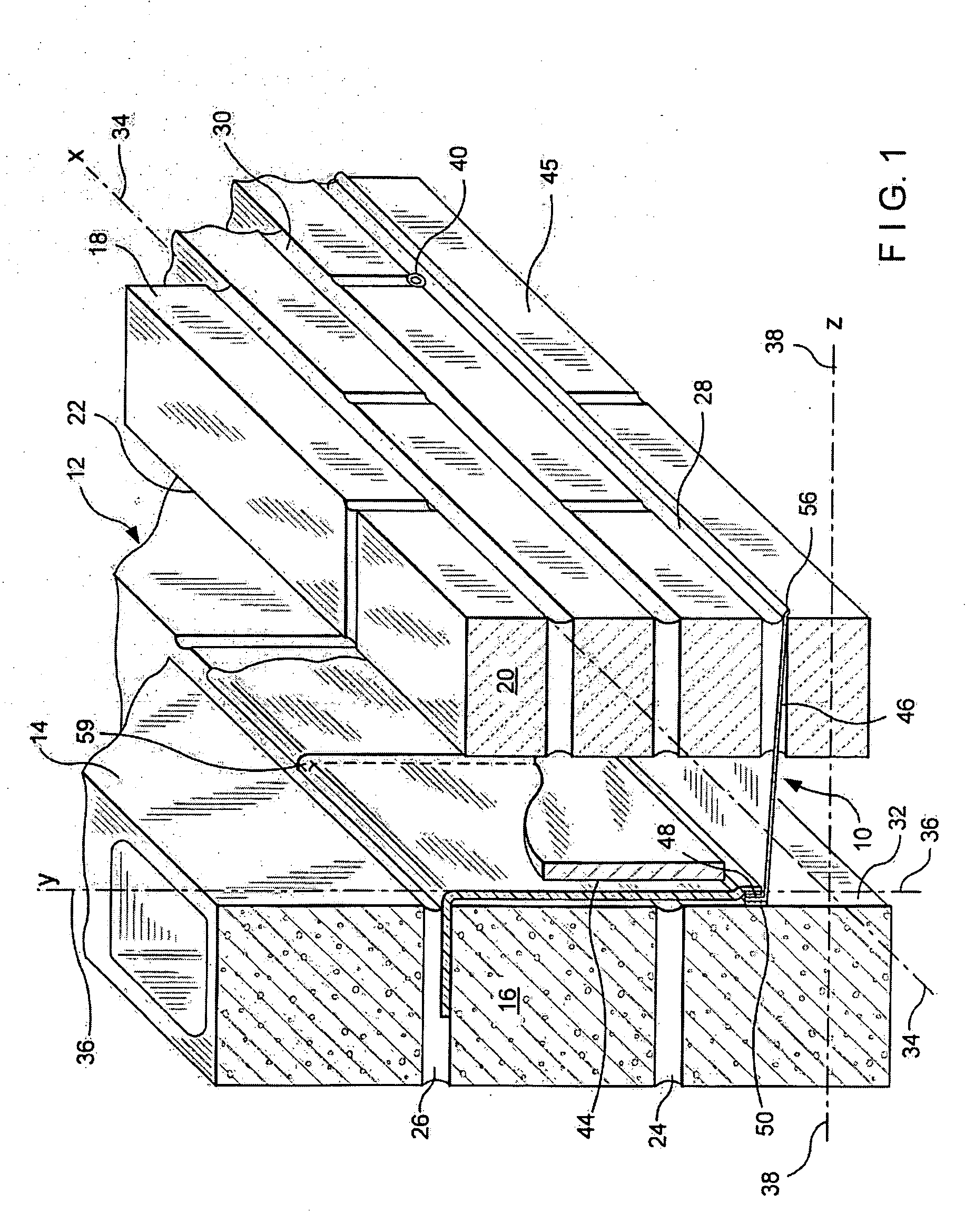

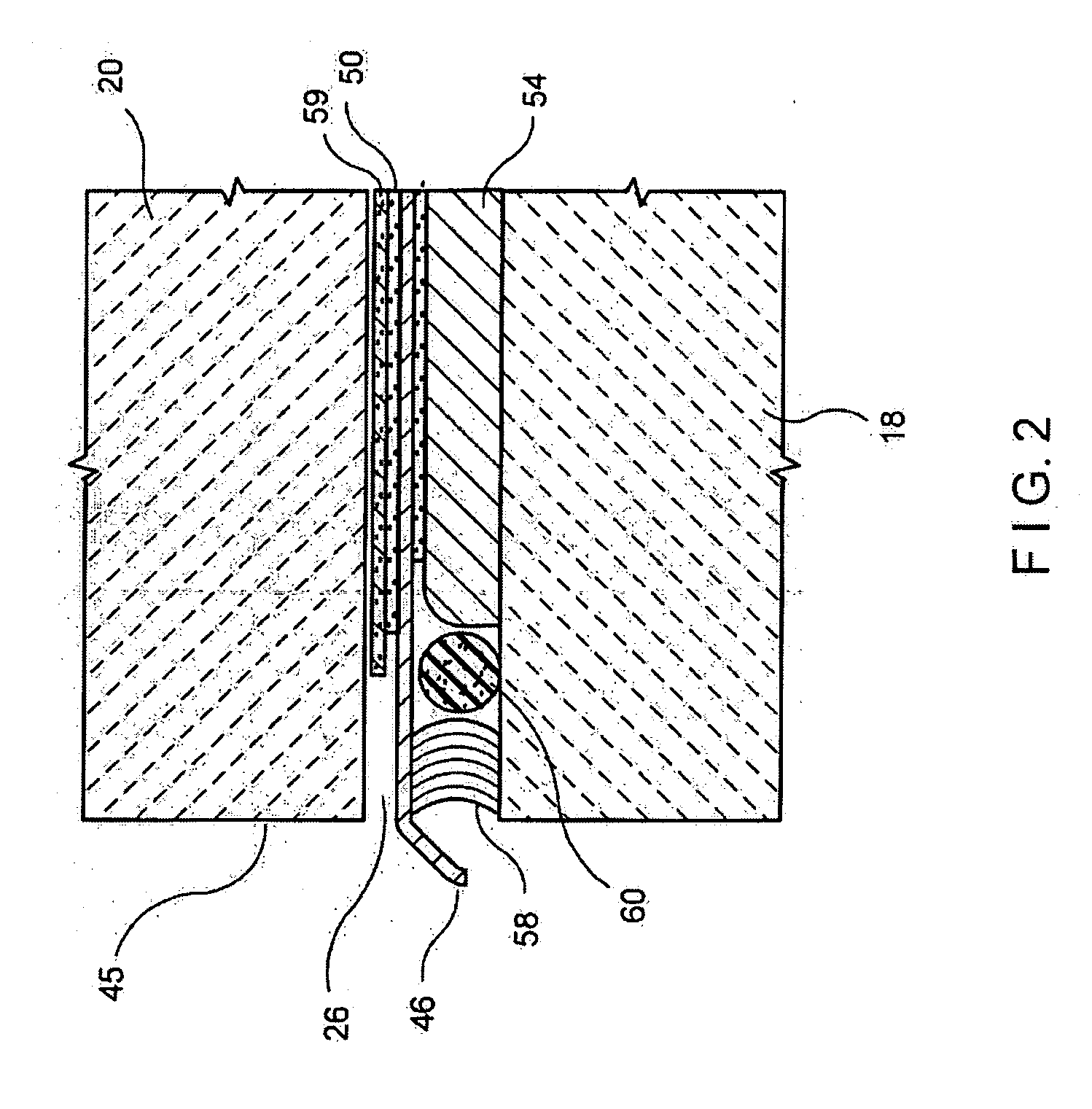

[0048]Referring now to FIGS. 1-3, views of the first embodiment of this invention in which a drainage system within a cavity wall structure, referred to generally by the reference designator 10, are shown. In this embodiment, a cavity wall structure 12 is shown having an inner wythe 14 of masonry blocks 16 and an outer wythe 18 of facing brick 20. Between the inner wythe 14 and the outer wythe 18, a cavity 22 is formed. Successive bed joints 24 and 26 are formed between courses of blocks 16 and the joints are substantially planar and horizontally disposed. Also, successive bed joints 28 and 30 are formed between courses of bricks 20 and the joints substantially planar and horizontally disposed. Selected bed joint 24 and bed joint 30 are constructed to align, that is to be substantially coplanar, the one with the other.

[0049]For purposes of this discussion, the exterior surface 32 of the inner wythe 14 contains a horizontal line or x-axis 34 and an intersecting vertical line or y-axi...

Example

[0064]Referring now to FIGS. 4 and 5, a perspective view of the second embodiment of this invention in which a surface-mounted drainage system, referred to generally by the reference designator 110, is shown. In this embodiment, similar parts to those of the first embodiment are referred to by reference designators 100 units higher than a similar part in the first embodiment. Thus, for example, the masonry block 16 in the first embodiment has an analogous masonry block 116 in the second embodiment. Here a cavity wall structure 112 is shown having an inner wythe 114 of masonry blocks 116 and an outer wythe 118 of facing brick 120. Between the inner wythe 114 and the outer wythe 118, a cavity 122 is formed and optional insulation 144 is shown. Successive bed joints 124 and 126 are formed between courses of blocks 116 and the joints are substantially planar and horizontally disposed. Also, successive bed joints 128 and 130 are formed between courses of bricks 120 and the joints are sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com