Ultra-High Strength Stainless Alloy Strip, a Method of Making Same, and a Method of Using Same for Making a Golf Club Head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

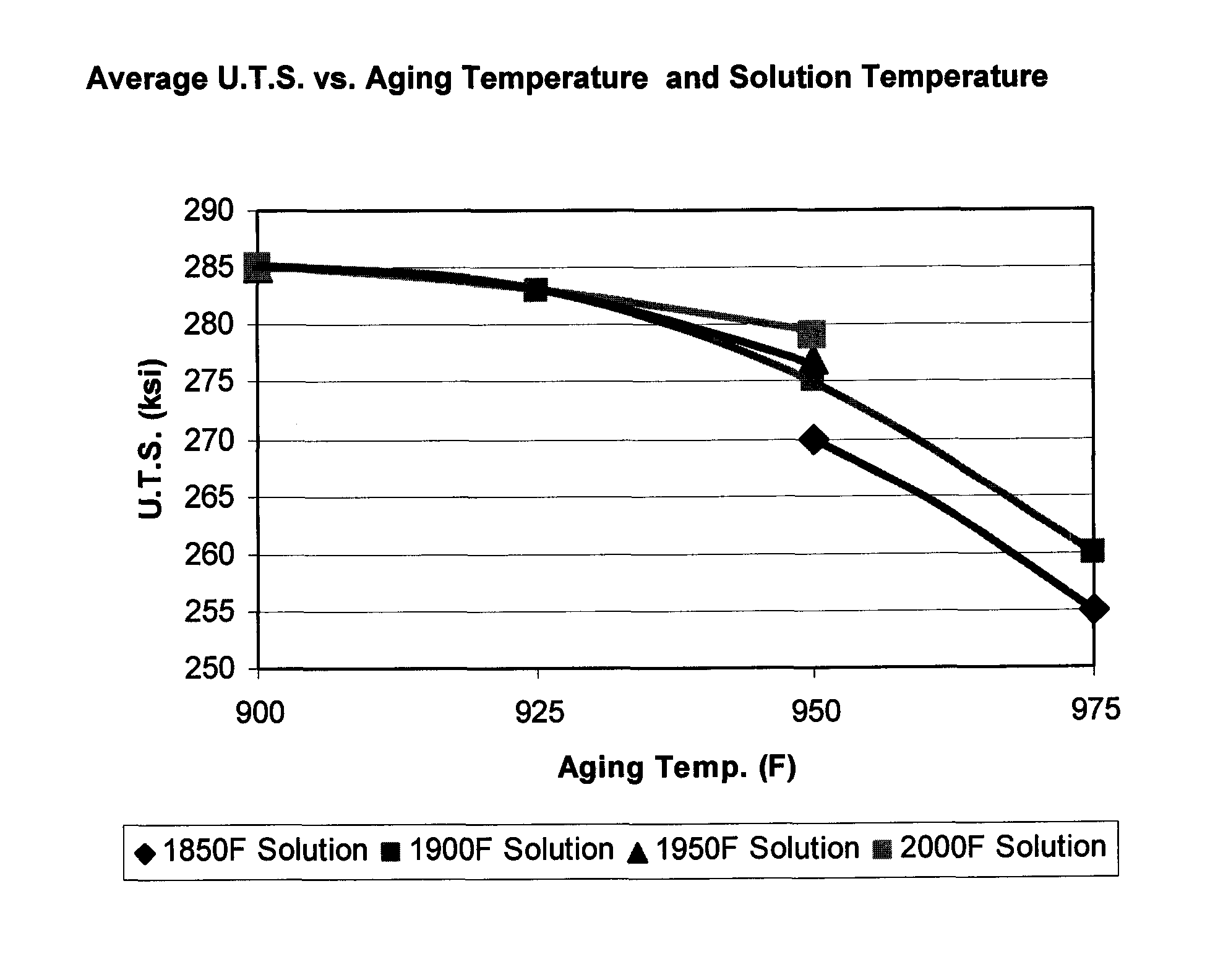

Image

Examples

Embodiment Construction

[0012]A preferred embodiment of the invention includes an elongated strip article having the following composition in weight percent:

C0.03max.Mn1.0max.Si0.75max.P0.040max.S0.020max.Cr10.9-11.1Ni10.9-11.1Mo0.9-1.1Ti1.5-1.6Al0.25max.Nb0.7-0.8Cu1max.B0.010max.N0.030max.

The balance is iron and the usual impurities.

[0013]The alloy composition is preferably melted using vacuum induction melting (VIM). The steel is cast into one or more ingot molds. For additional cleanness, the alloy is vacuum arc remelted (VAR) after the VIM step. After solidification, the alloy is formed into strip by intermediate pressing of the ingot to form a billet and then hot rolling the billet to form elongated strip. Alternatively, the strip material can be formed by hot rolling the ingot from a starting temperature of about 1900° F. to 2250° F. The strip can be provided in the overaged condition by heating at about 1100° F. to 1350° F. for about 2 to 8 hours and then cooling in air. Alternatively, and for bette...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com