Sensor device and sensor-integrated rolling bearing device

a technology of sensor and rolling bearing, which is applied in the direction of instruments, mechanical equipment, transportation and packaging, etc., can solve the problems of reducing the sealing performance of the fitting part, deteriorating the fitting cylindrical part of the finished core, and hardening of the elastic seal b>163/b>

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

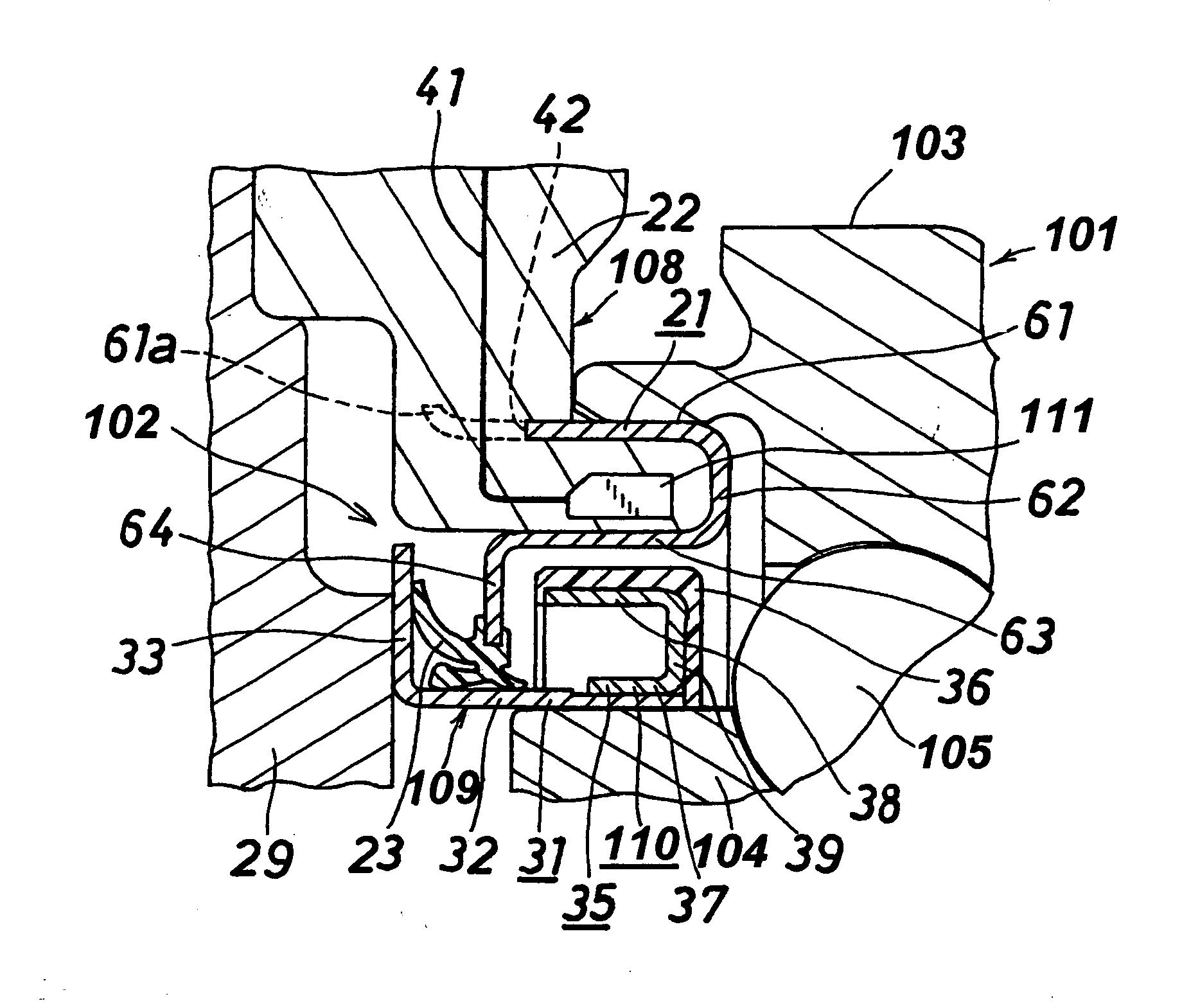

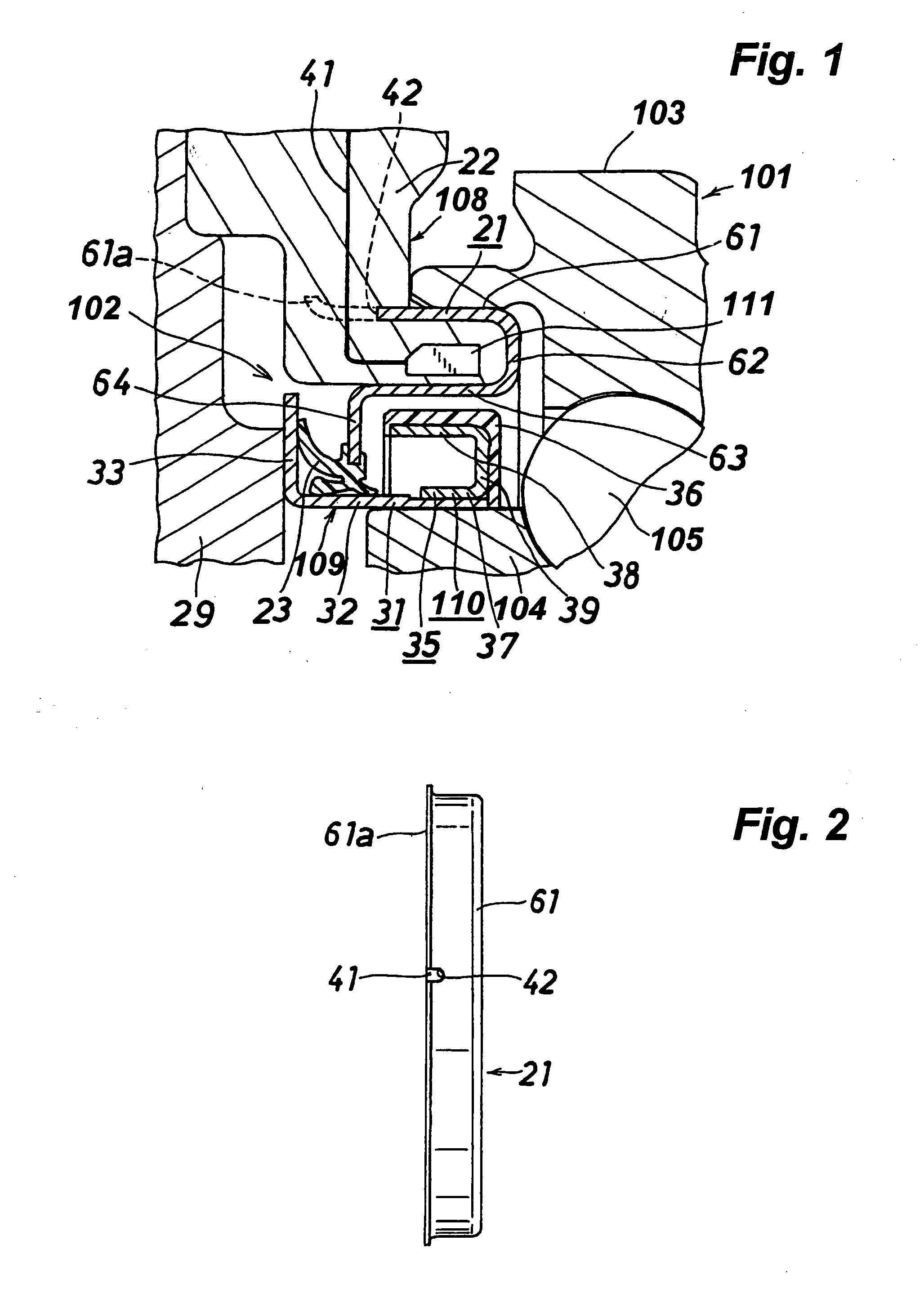

[0107]FIGS. 1 and 2 show a sensor device and a sensor-integrated rolling bearing device according to the invention. It is to be noted that in the following description, a right side and a left side correspond to a right side and a left side in FIG. 1. Moreover, an inside of a vehicle is the left side, and an outside of the vehicle is the right side.

[0108]The sensor-integrated rolling bearing device includes a hub unit 1 and a sensor-integrated sealing device 2.

[0109]The hub unit 1 is the same as the hub unit as shown in FIG. 5, and includes: a body-side raceway member 3 which is fixed to a vehicle body; a wheel-side raceway member 4 to which a vehicle wheel is fitted; and a plurality of balls 5 as rolling elements which are arranged in two rows between the two raceway members 3 and 4.

[0110]The sensor-integrated sealing device 2 includes: a fixed-side sealing member 8 which is fixed to the body-side raceway member 3; and a rotation-side sealing member 9 which is fixed to the wheel-si...

second embodiment

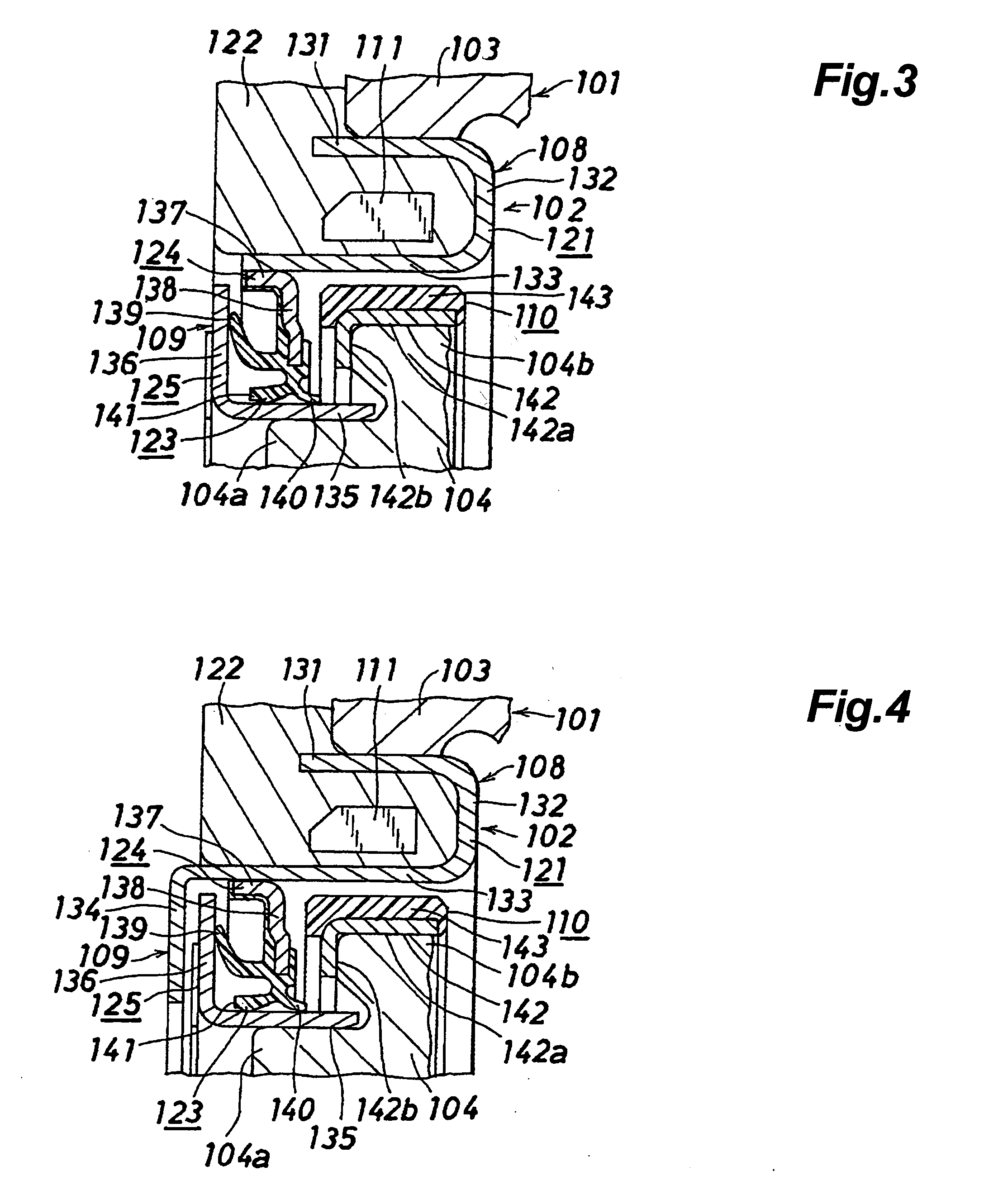

[0124]FIG. 3 shows a sensor-integrated sealing device and a rolling bearing device using the same according to the invention. It is to be noted that in the following description, a right side and a left side correspond to a right side and a left side in FIG. 3. Moreover, an inside of a vehicle is the left side, and an outside of the vehicle is the right side.

[0125]The sensor-integrated rolling bearing device includes a hub unit 101 and a sensor-integrated sealing device 102.

[0126]The hub unit 101 is the same as the hub unit as shown in FIG. 6, and includes: a body-side raceway member 103 which is fixed to a vehicle body; and a wheel-side raceway member 104 to which a wheel is fitted. A left part of the wheel-side raceway member 104 is formed in a stepped shape, and has a small-diameter part 4a at a left end, and a large-diameter part 104b which is continued from a right side of the small-diameter part 4a.

[0127]The sensor-integrated sealing device 102 includes: a fixed-side sealing ...

third embodiment

[0141]Therefore, according to the sensor-integrated sealing device 102 in the third embodiment, as compared with the conventional sealing device in which a sealing member called as a deflector is press-attached to the constant velocity joint or the like thereby to assist the sealing performance of the sealing device, thereby making such a sealing member unnecessary.

[0142]The above-described sealing device 102 with the sensor can be used in the hub unit 101 for a driving wheel or a driven wheel, and can be also used in various types of rolling bearing devices and in various types of rotary devices which are relatively rotated, besides the hub unit 101.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com