Vane structure for vertical axis wind power generator

a technology of wind power generator and vertical axis, which is applied in the direction of machines/engines, renewable energy generation, greenhouse gas reduction, etc., can solve the problems of disadvantageous reduction of wind power generation accordingly, and achieve the effect of effectively intercepting wind power, effective utilization of wind power, and increasing air resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will now be described with two preferred embodiments thereof. For the purpose of easy to understand, elements that are the same in the two preferred embodiments are denoted by the same reference numerals.

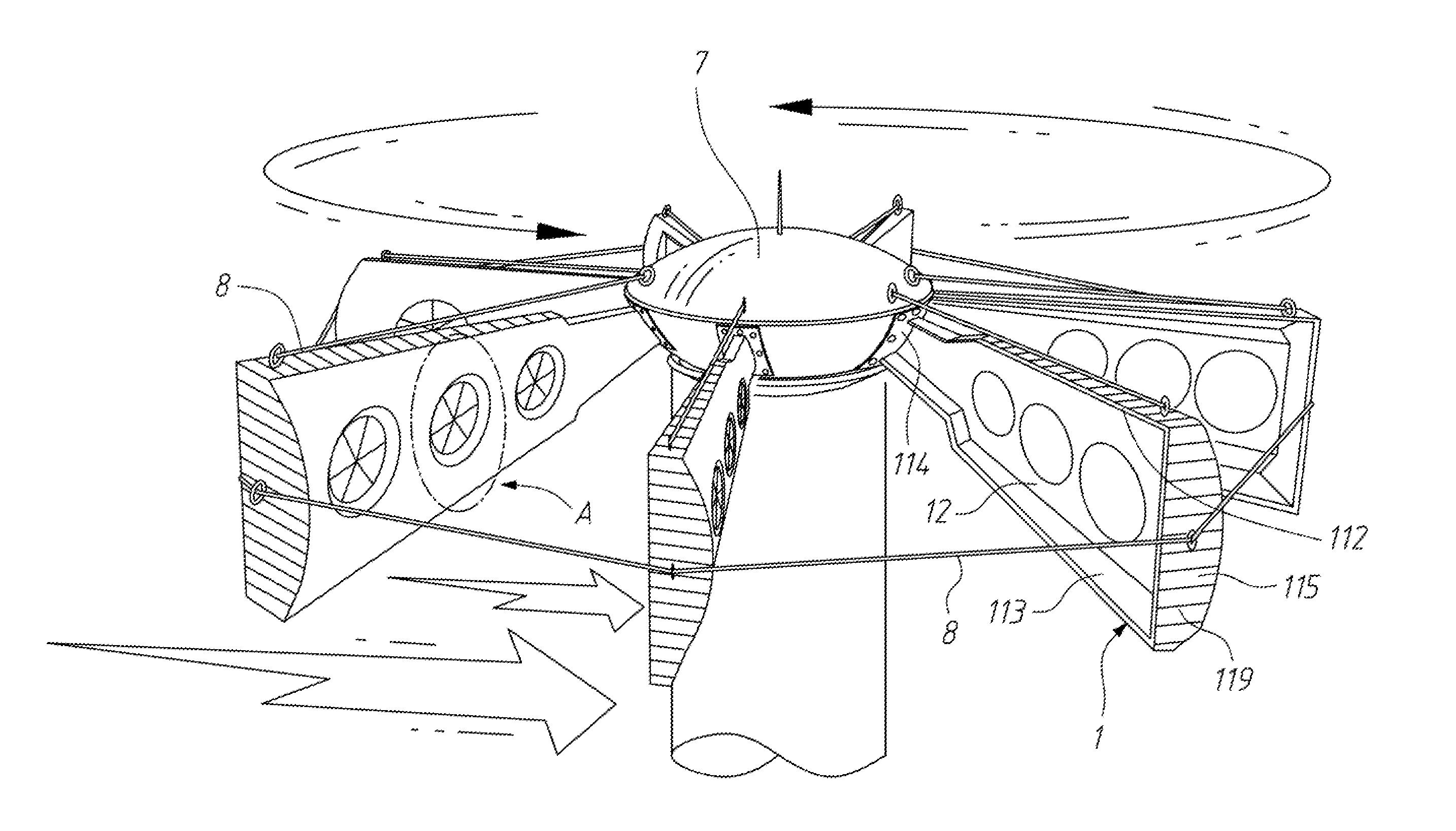

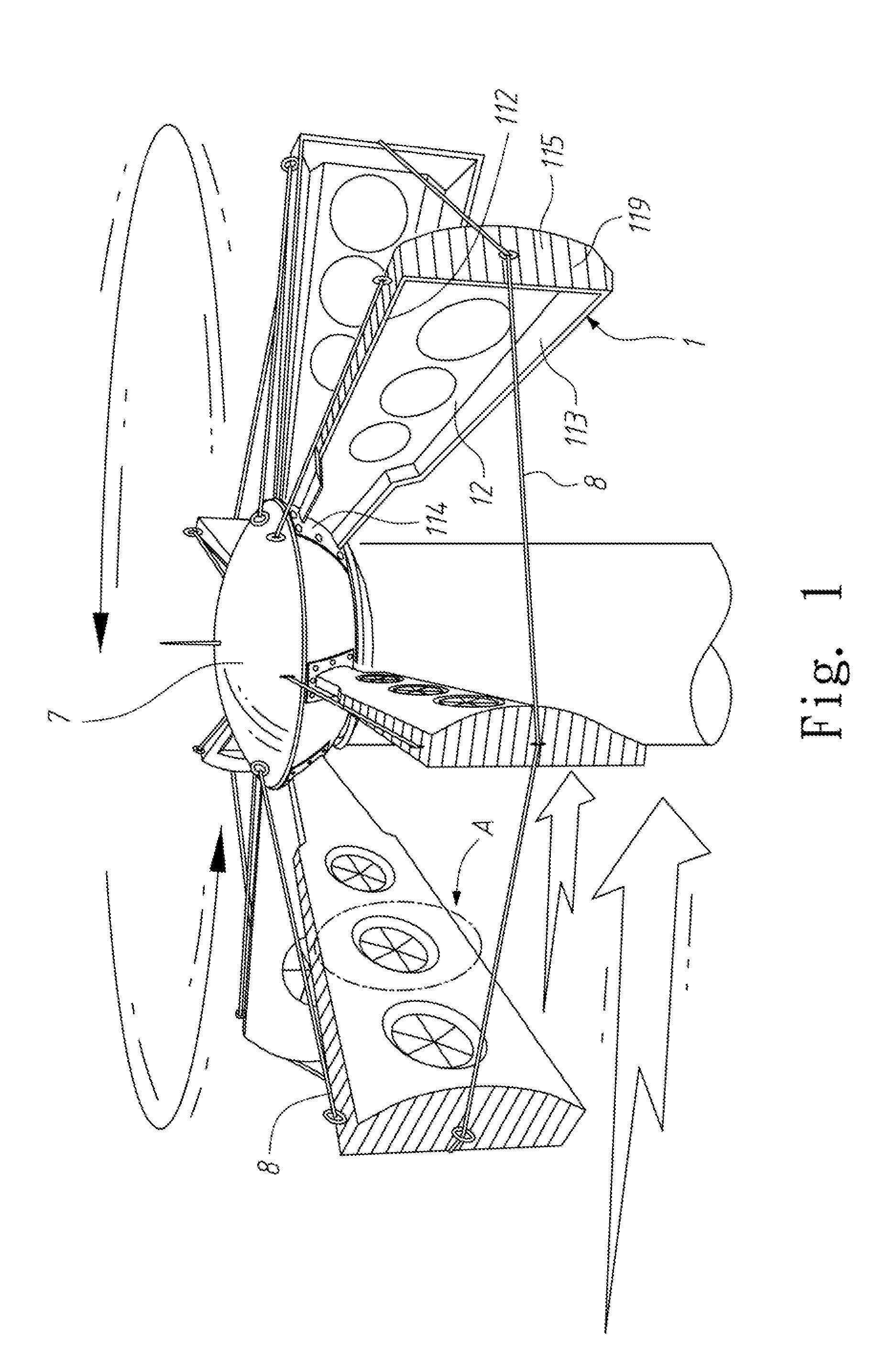

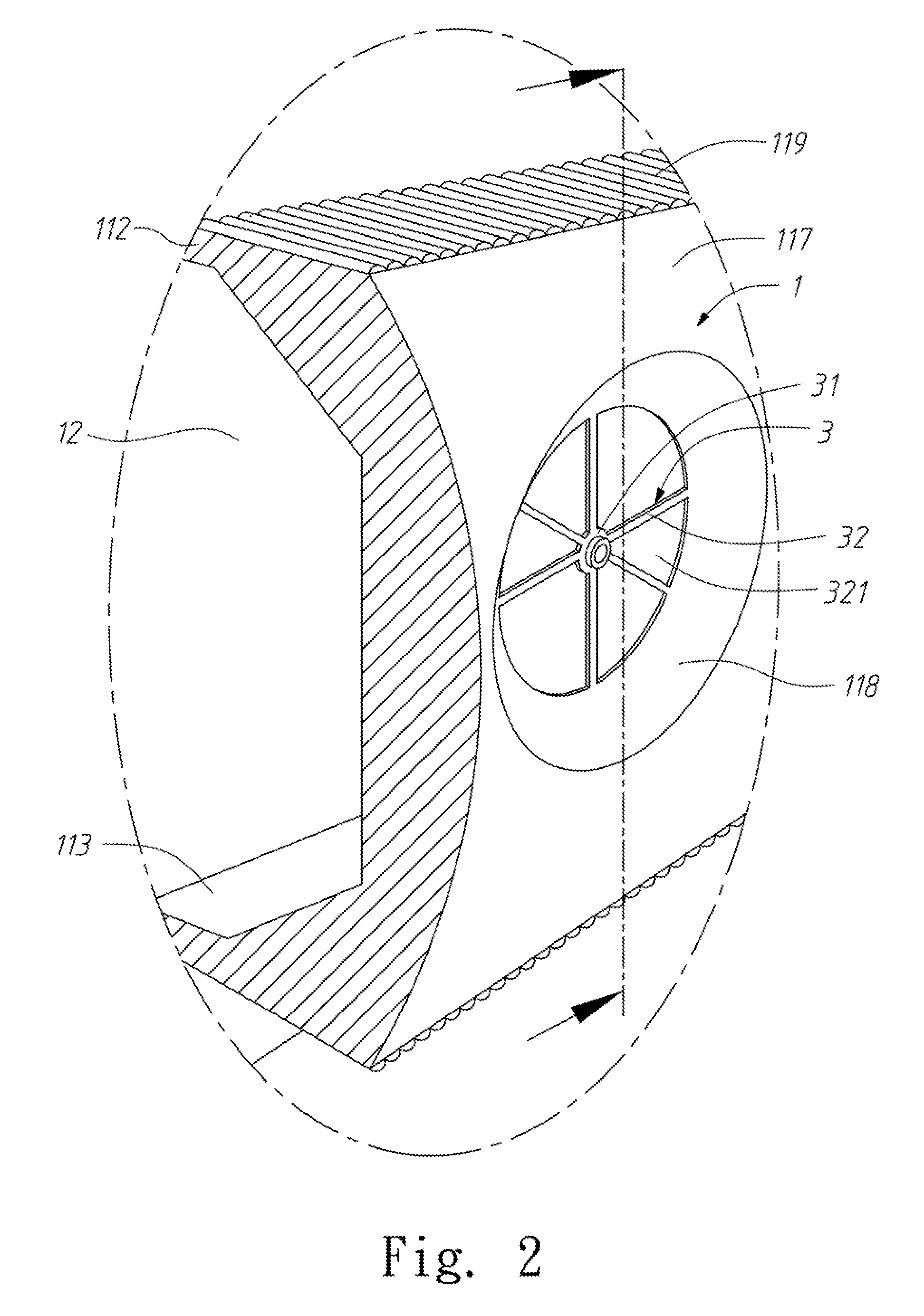

[0031]Please refer to FIG. 1 that is a fragmentary perspective view showing a plurality of vanes according to the present invention is mounted around and spaced along a main shaft 7 of a wind power generator, and to FIG. 2 that is an enlarged and partially sectioned perspective view of the circled area A of FIG. 1, and to FIGS. 3 to 5 that are sectioned side views of one vane according to a first embodiment of the present invention.

[0032]As shown, the vane structure for vertical axis wind power generator according to the first embodiment of the present invention includes a plurality of vanes, each of which includes a vane body 1, a first arcuate guide bar 2, an openwork screen 3, and a first movable baffle unit 4.

[0033]The vane body 1 includes a body port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com