Heat dissipation device with heat pipe

a heat pipe and heat dissipation device technology, applied in the direction of semiconductor devices, lighting and heating apparatus, tubular elements, etc., can solve the problem of limiting the applicability of heat pipes to dissipate hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

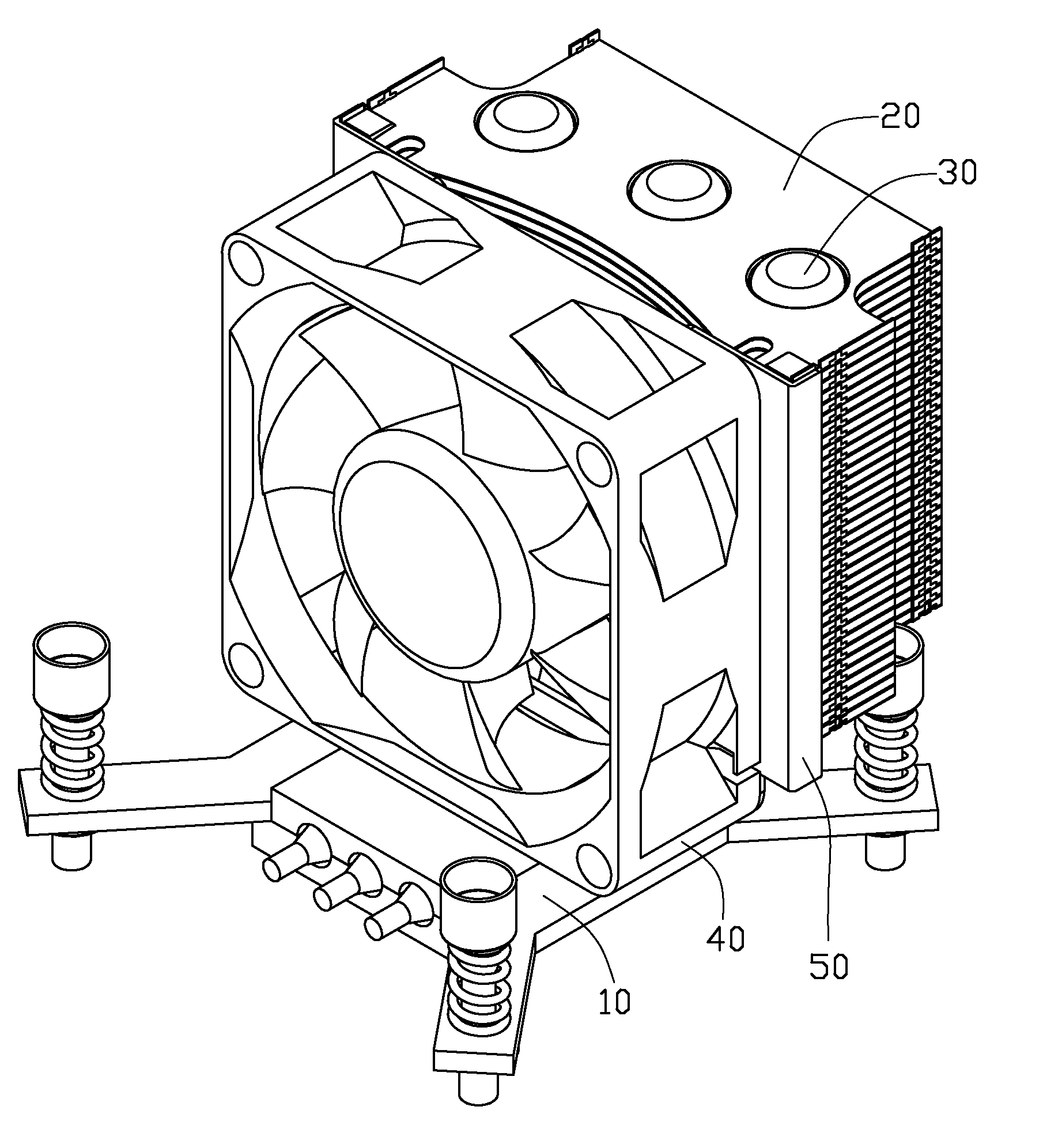

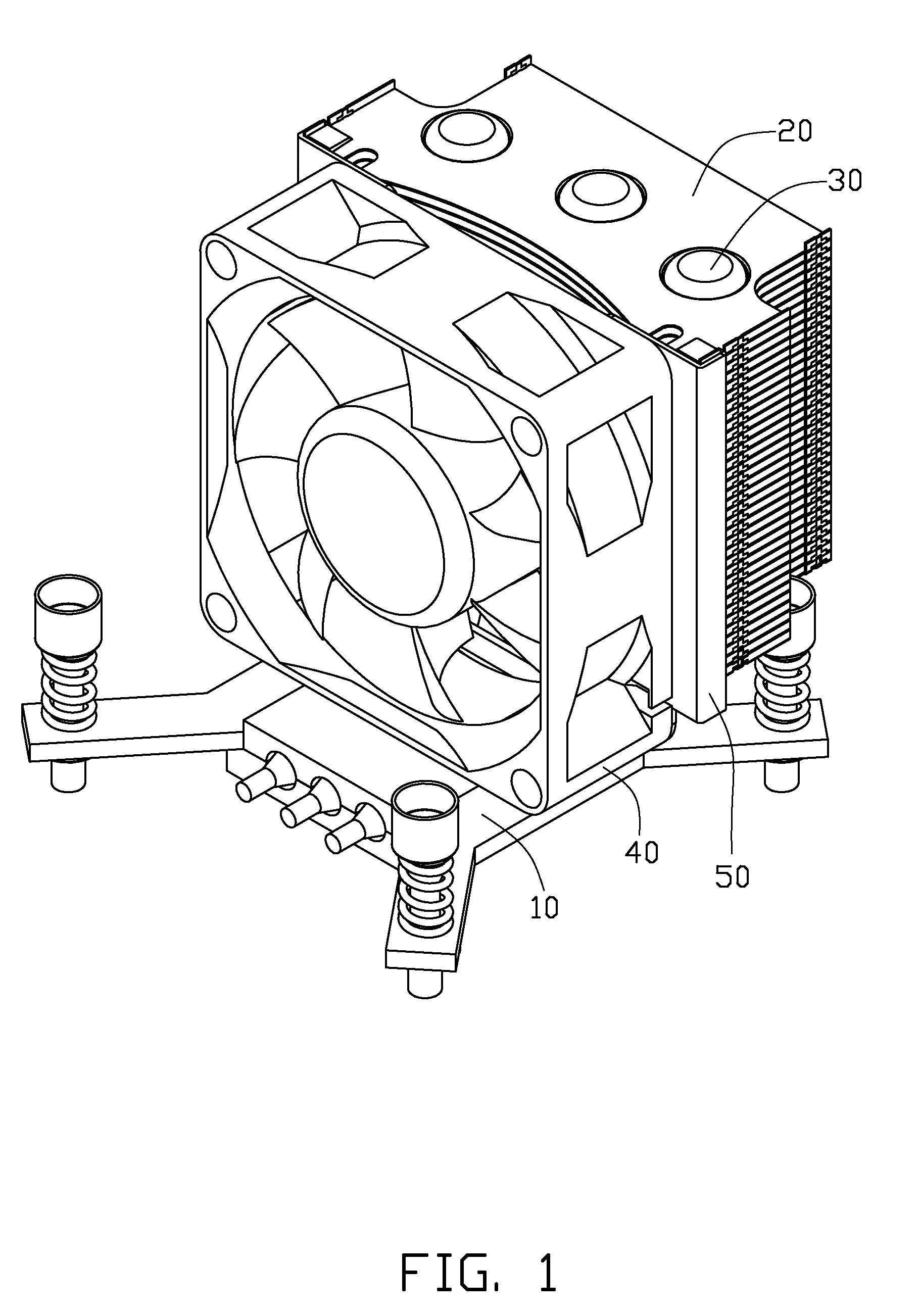

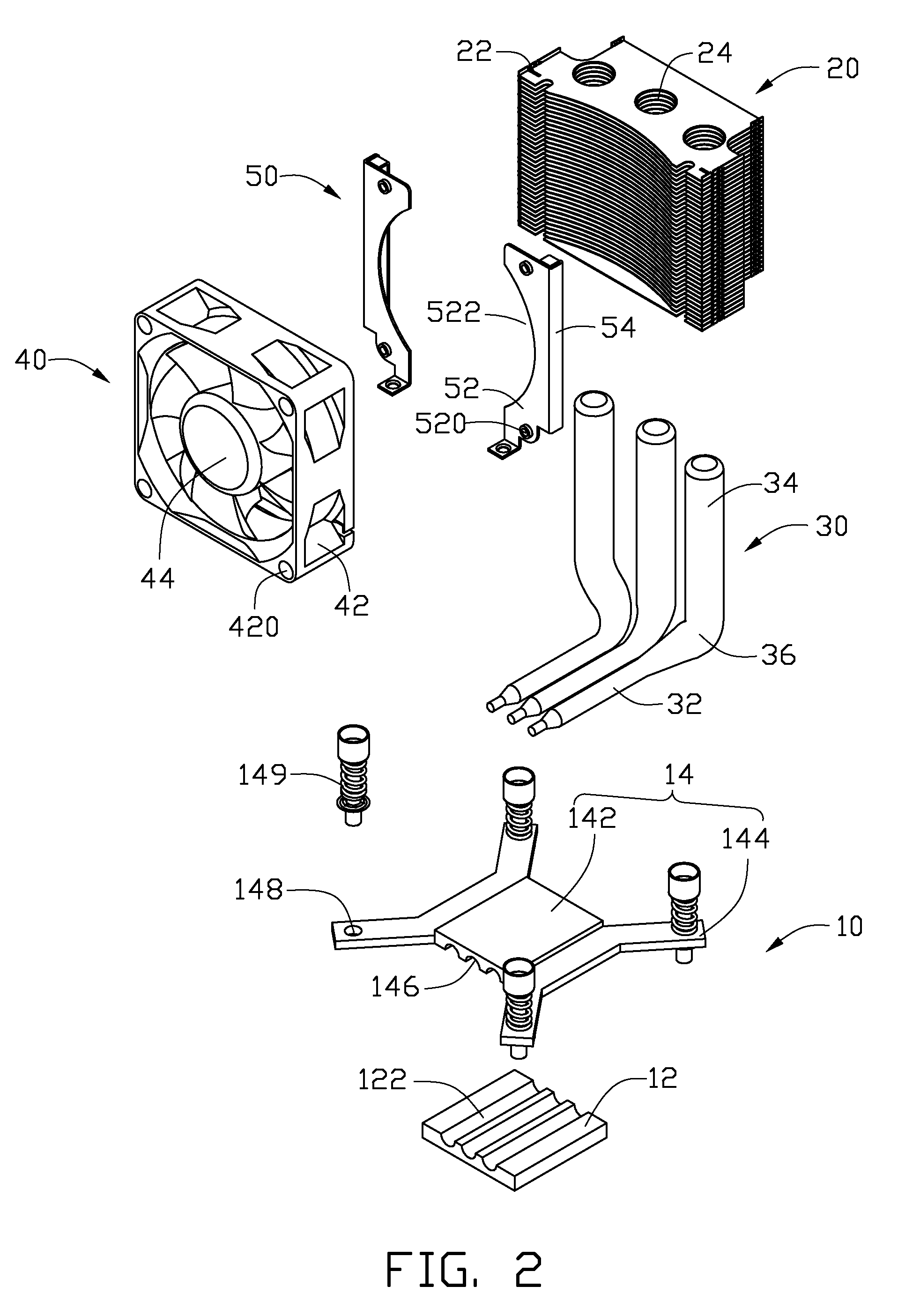

[0011]FIG. 1 shows a heat dissipation device in accordance with an embodiment of the disclosure. The heat dissipation device dissipates heat generated by an electronic device (not shown). The heat dissipation device comprises a heat spreader 10, a fin assembly 20 above the heat spreader 10, three heat pipes 30 thermally connecting the heat spreader 10 with the fin assembly 20, a fan 40 and two fixing brackets 50 fixing the fan 40 to the fin assembly 20.

[0012]Also referring to FIG. 2, the heat spreader 10 is made of metal such as aluminum, copper or an alloy thereof. The heat spreader 10 includes a bottom plate 12 and a top plate 14 above the bottom plate 12. The bottom plate 12 defines three parallel, spaced first grooves 122 in a top thereof. The top plate 14 includes a rectangular body 142 and four ears 144 extending outwardly from four corners of the body 142. The body 142 defines three parallel, spaced second grooves 146 in a bottom thereof, corresponding to the first grooves 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com