Offshore oil production platform

a technology of oil production platform and oil tank, which is applied in the direction of underwater structures, artificial islands, hydroelectric engineering, etc., can solve the problems of increasing the cost and reliability of the platform, the difficulty of drilling,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]A detailed description of preferred embodiments of the invention is disclosed herein. It should be understood, however, that the disclosed preferred embodiments are merely exemplary of the invention, which may be embodied in various forms. Therefore, the details disclosed herein are not to be interpreted as limiting, but merely as the basis for the claims and for teaching one skilled in the art of the invention.

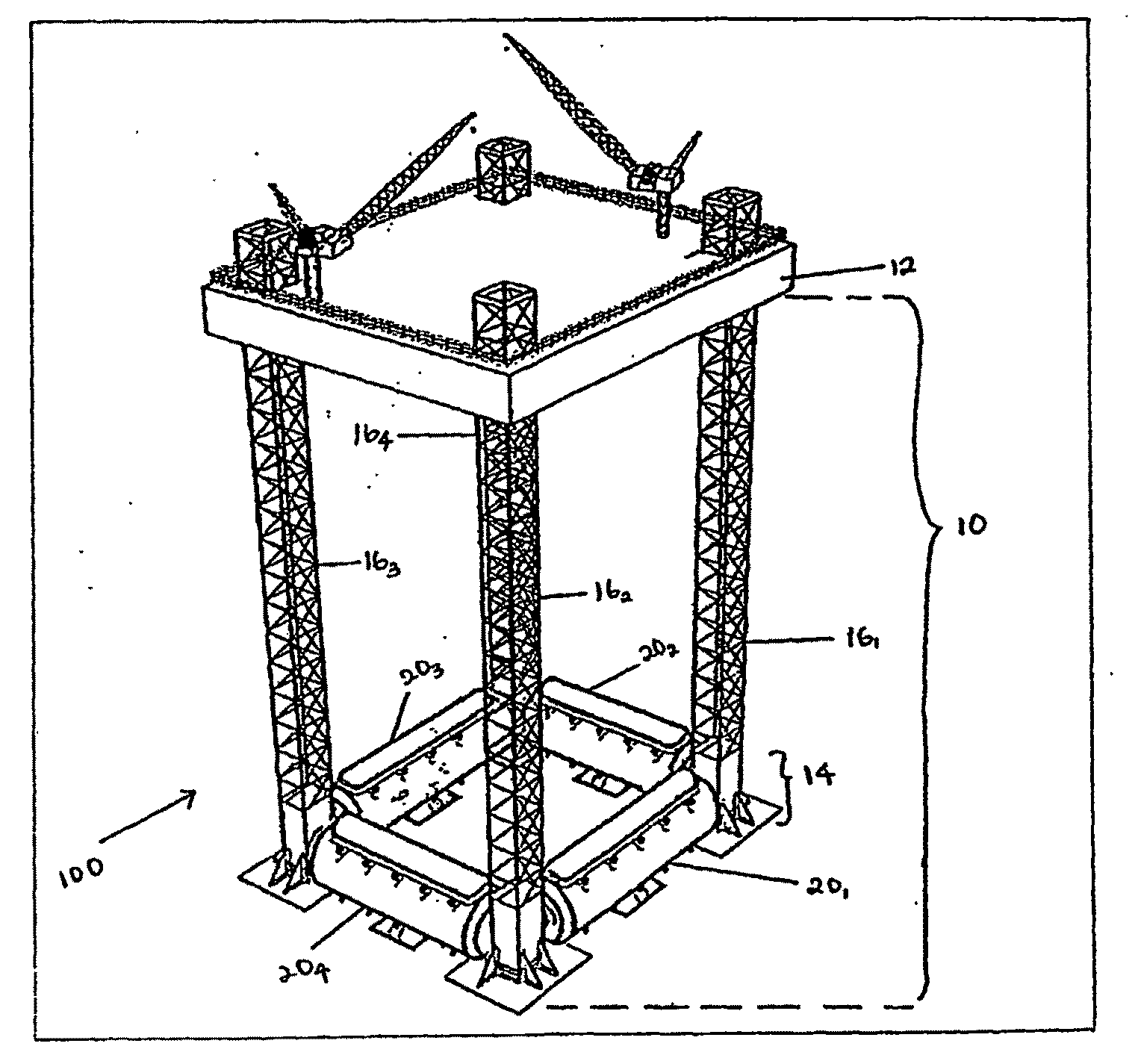

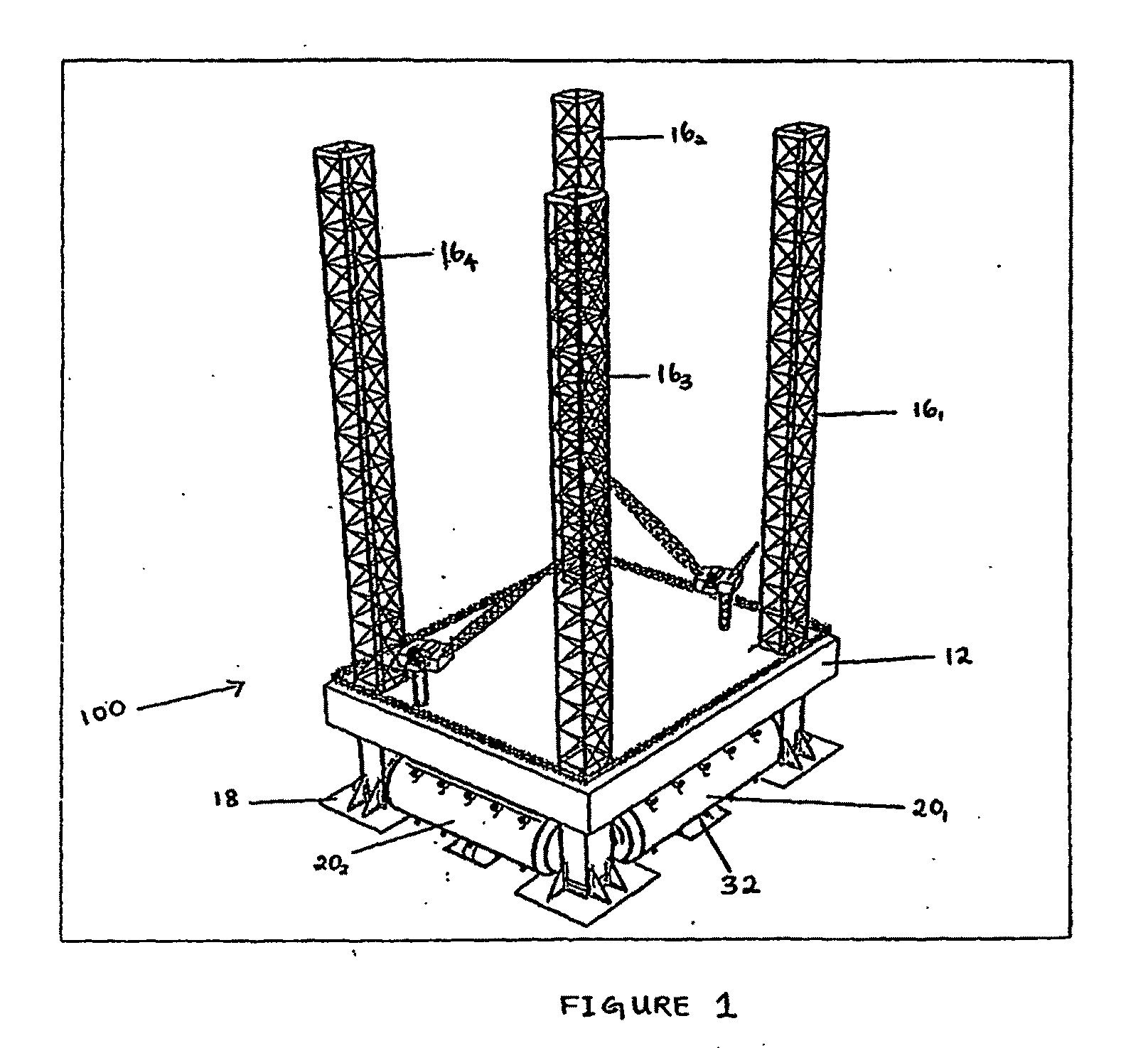

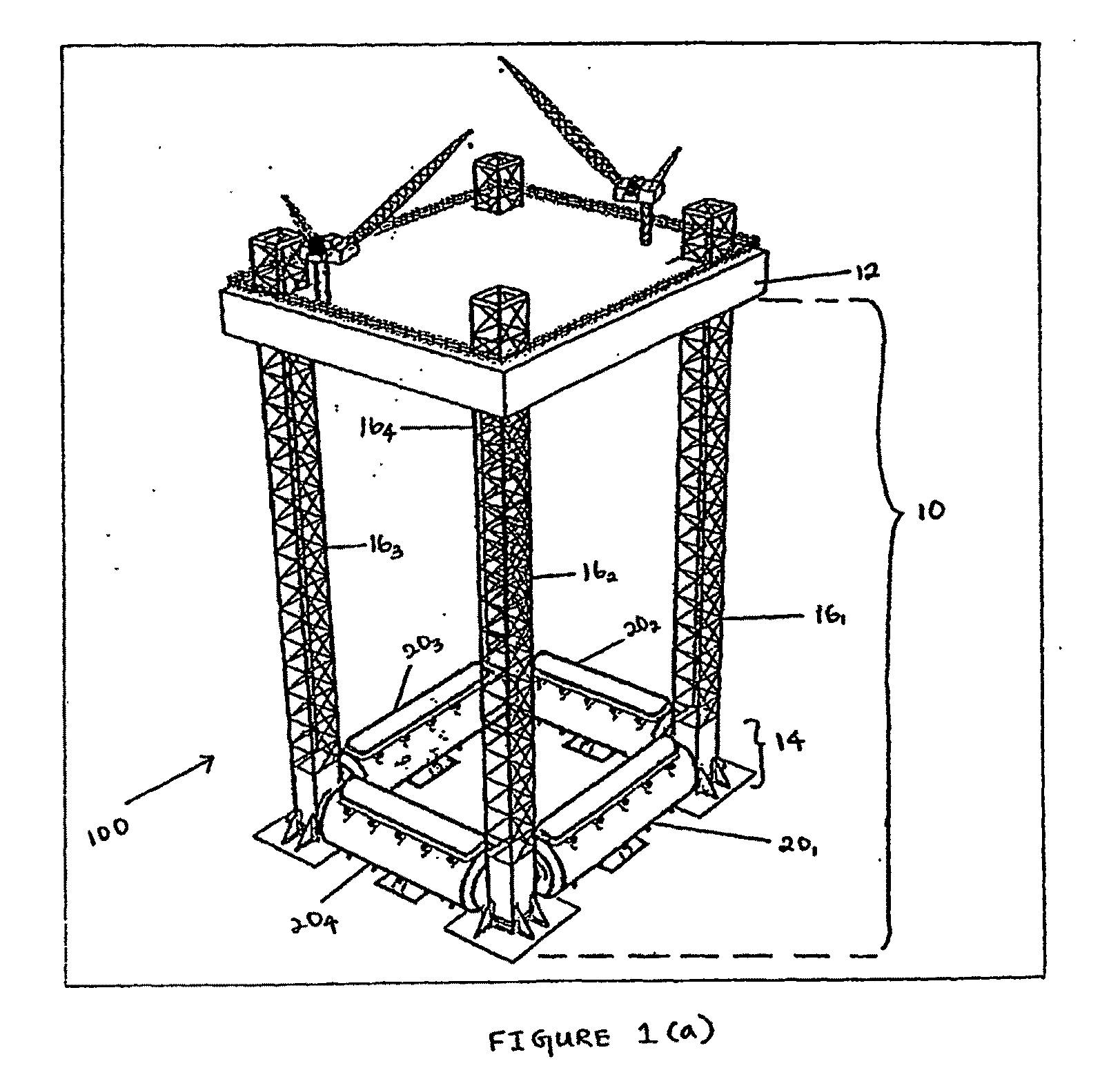

[0030]FIG. 1 is a diagrammatic view illustrating a first preferred embodiment of an offshore oil production platform before being towed to an oil extraction destination. The oil production platform includes a sub-structure (10) and a deck (12). The sub-structure (10) comprises a base (14) comprising with four ballast chambers (201), (202), (203), (204) connected to one terminal end region of four connecting legs (columns or jackets) (161), (162), (163), (164) respectively upstanding from the ballast chambers (20) to above the deck (12). The ballast chambers (20) connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com