Air Supply Unit

a technology of air supply and air supply, which is applied in the direction of energy-efficient heating/cooling, sustainable buildings, heating fuel, etc., can solve the problem that the efficiency of the heat pump remains unoptimal for heating us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

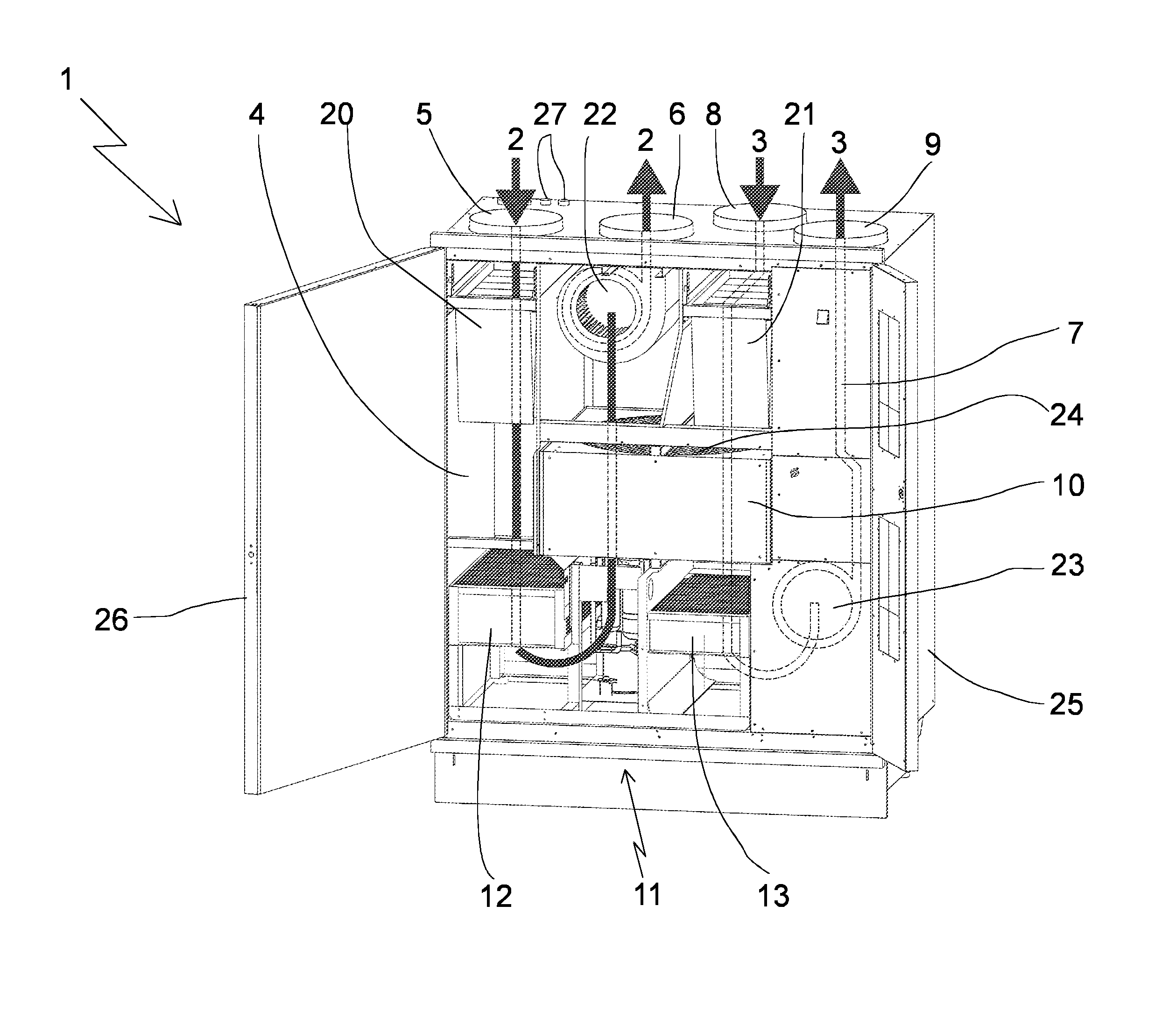

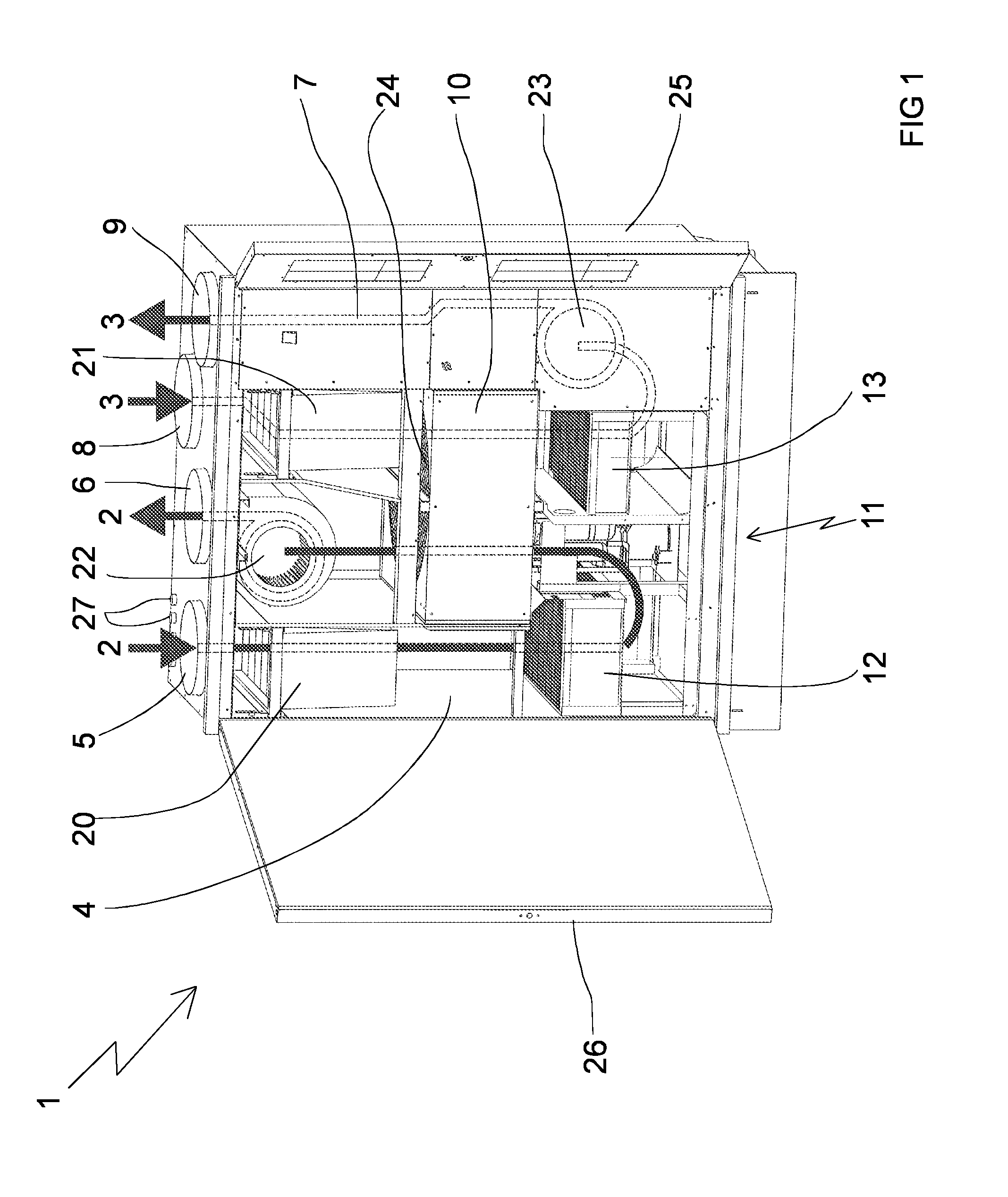

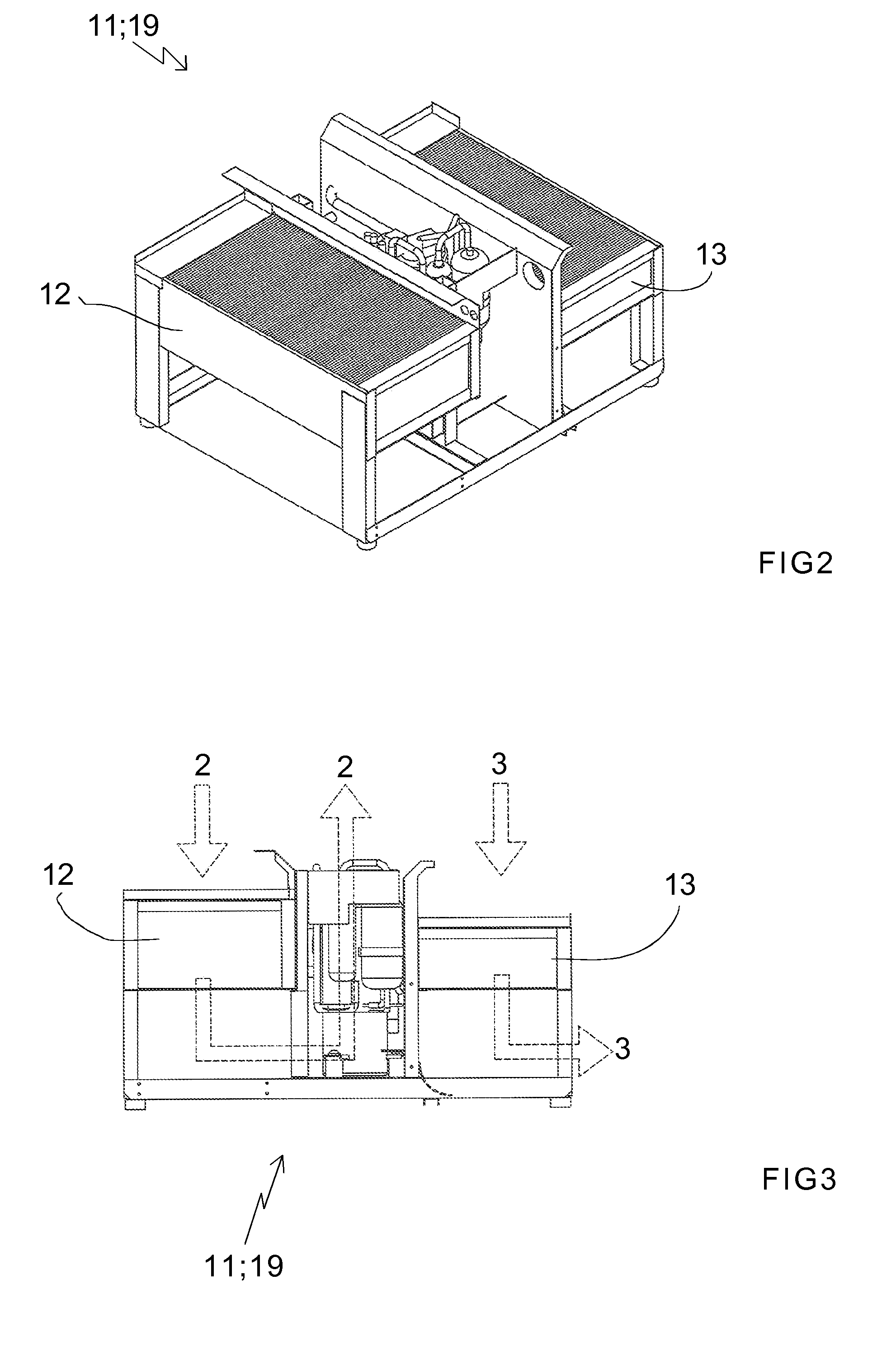

[0028]FIG. 1 depicts an air supply unit 1 for extracting heat energy (not shown in the figures) from exhaust air 2 and transferring the heat energy to supply air 3.

[0029]The air supply unit 1 comprises a casing 25.

[0030]In casing 25, the air supply unit 1 comprises an exhaust air channel 4 for leading exhaust air 2 through the casing 25 of the air supply unit 1.

[0031]The exhaust air channel 4 has a first inlet 5 for leading exhaust air 2 into the exhaust air channel 4 and a first outlet 6 for removing the exhaust air 2 from the exhaust air channel 4. In FIG. 1, the first inlet 5 and the first outlet 6 are equipped with belled pipes (not indicated by a reference number) for connecting the air supply unit 1 for example with air conditioning channels or similar ducts.

[0032]In the air supply unit 1 shown in FIG. 1, the exhaust air channel 4 is composed of the walls, separation walls, bottom and ceiling of the casing 25 of the air supply unit 1. The exhaust air channel 4 of the air suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com