System for flat-roof installation of solar modules

a solar module and installation system technology, applied in the direction of solar heat collector mounting/support, photovoltaics, etc., can solve the problems of expensive sealing measures at the penetration points, and the function of the watertight roof element is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

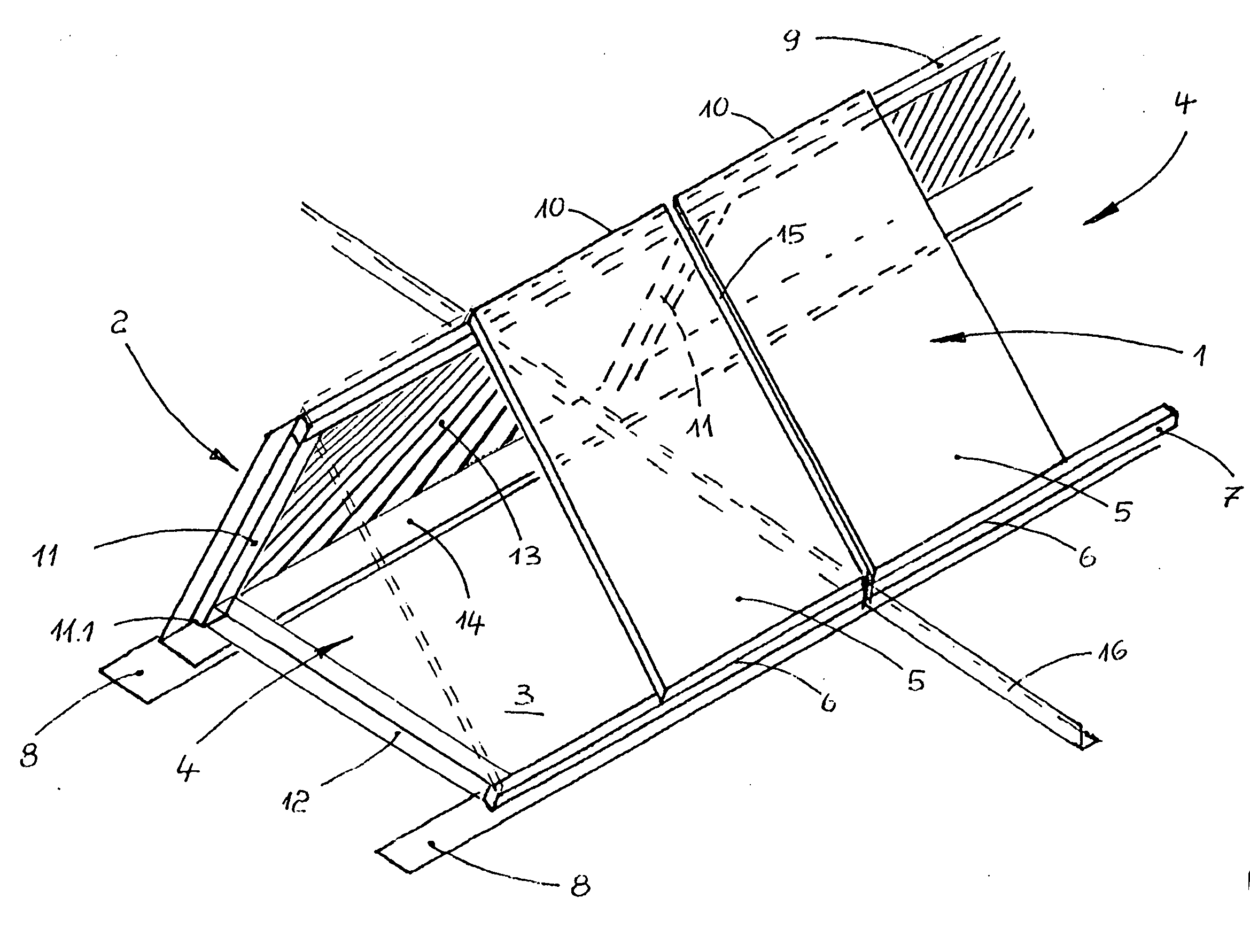

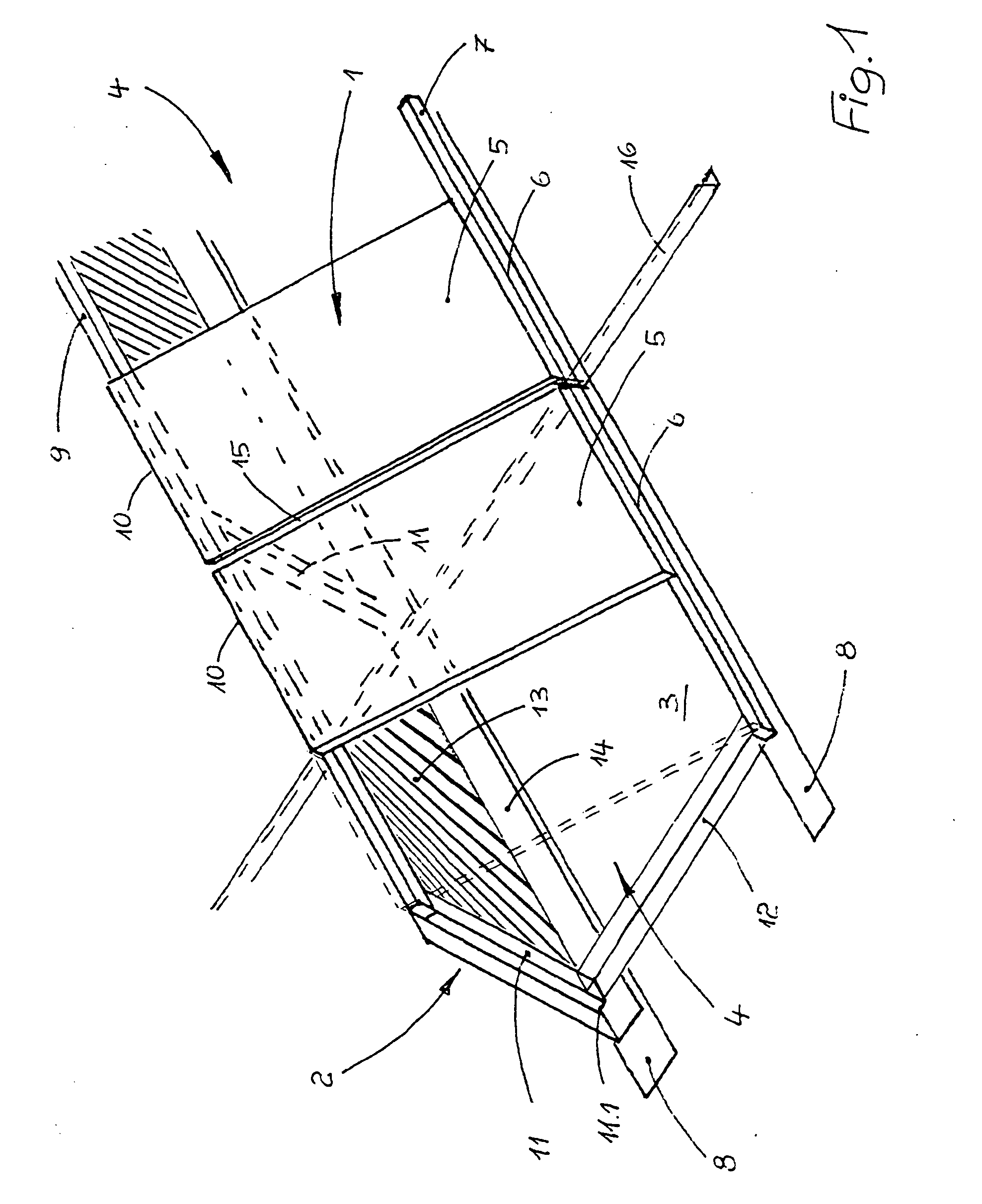

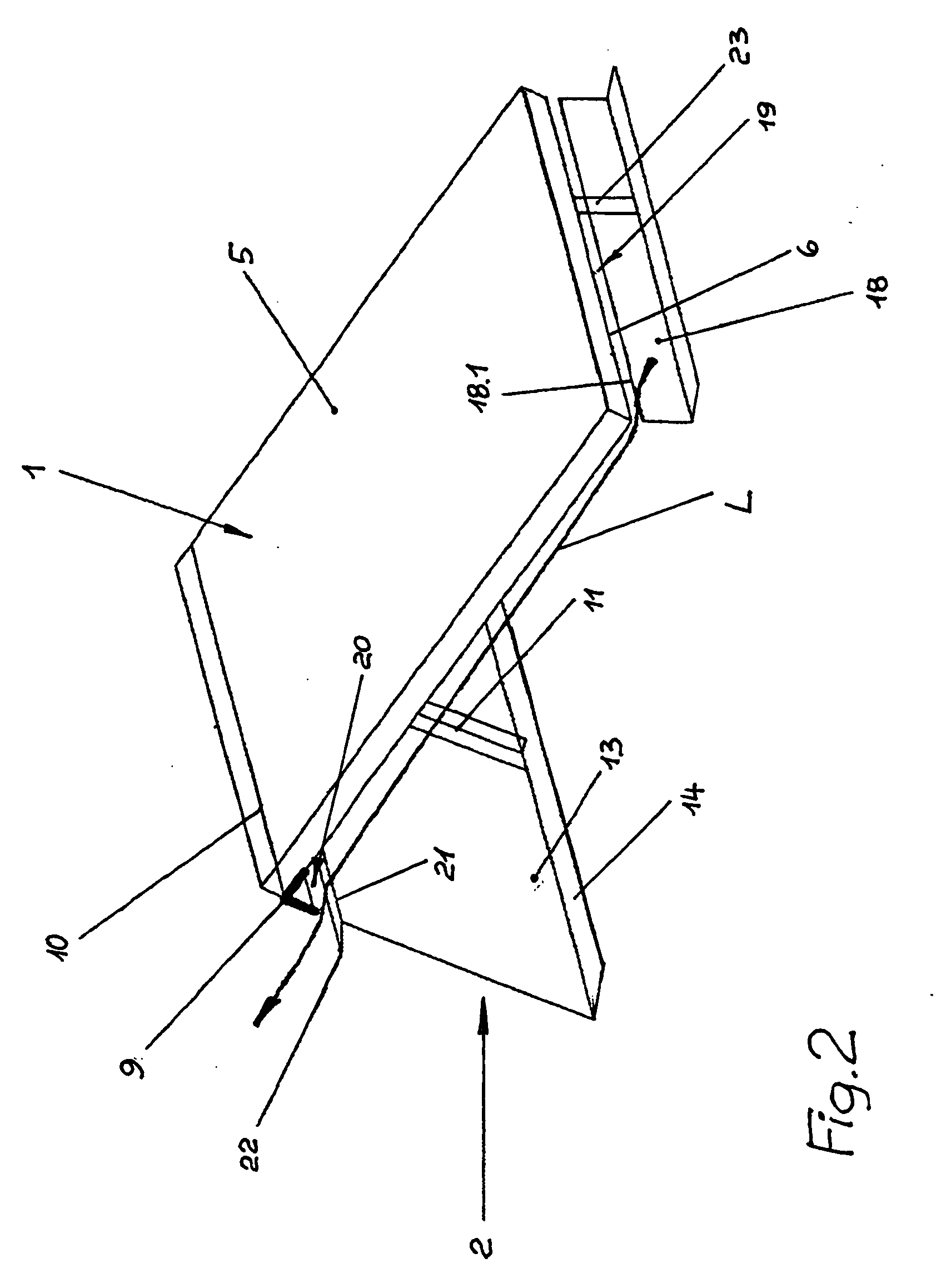

[0011]Specifically, one may recognize in FIG. 1 a solar module flat-roof installation set that has the shape of an acutely-angled or right-angled ridge roof. Thus, the flat-roof installation set possesses a first side 1, a second 2 positioned at an acute or right angle with respect to the first side 1, and face sides or end regions 4 open at both ends. When in operating position, the open underside of the flat-roof installation set is closed by the roof surface 3 that is correspondingly watertight and also airtight.

[0012]The first side 1 of the flat-roof installation set is provided with solar modules 5 that possess the shape of rectangular or square panels mounted in a common plane inclined relative to the roof surface 3. The solar modules 5 are a component of a photo-voltaic system, and generally are mounted in some quantity adjacent to one another as is known in the art of photo-voltaic systems. For this, the lower edges 6 and the upper edges 10 of the solar modules 5 are aligned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com