Ceiling-embedded air conditioner

a ceiling-embedded, air-conditioning technology, applied in the field of ceiling-embedded air-conditioning, can solve the problems of high manufacturing cost, complex structure of the air passage, etc., and achieve the effect of simple structure and prevention of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

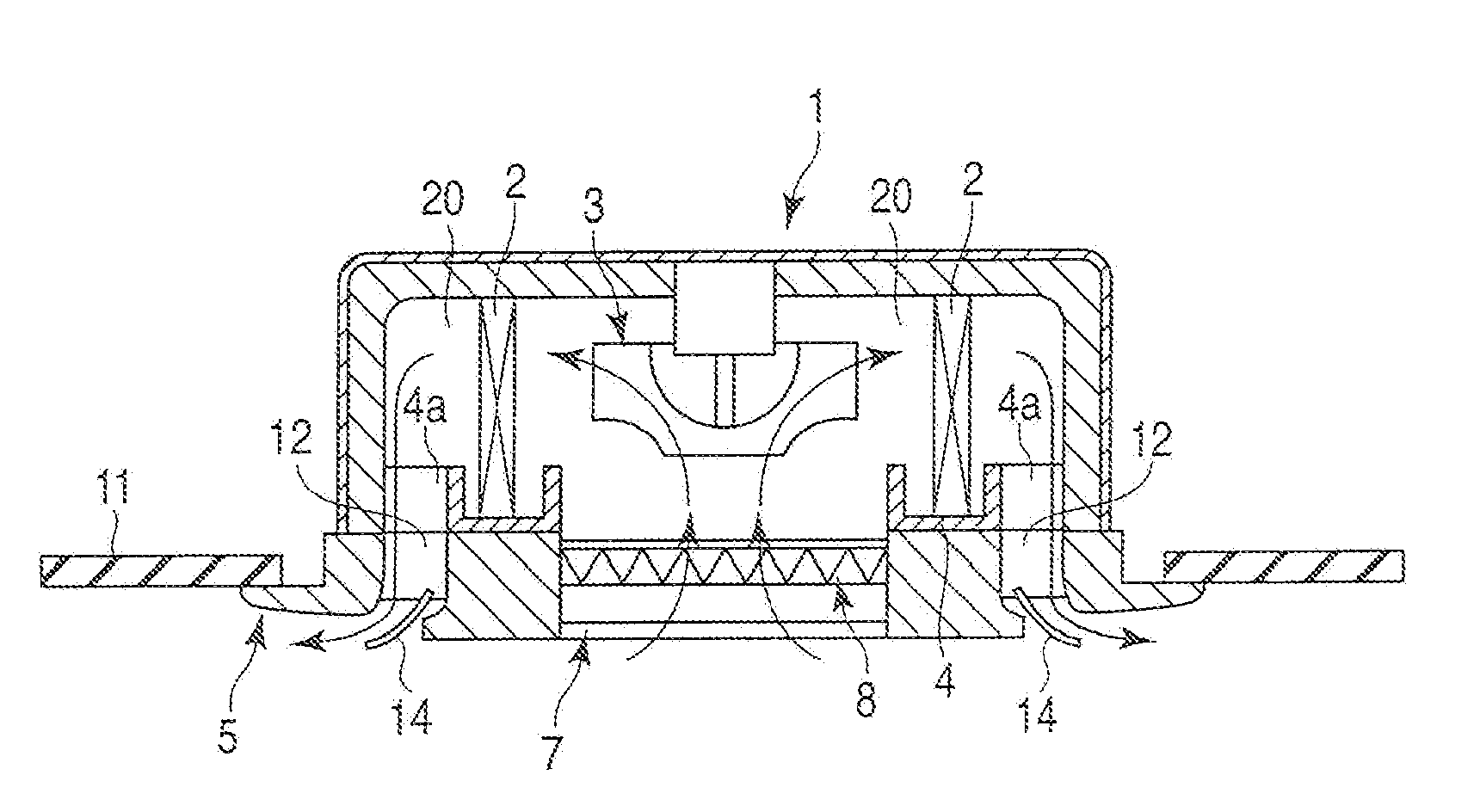

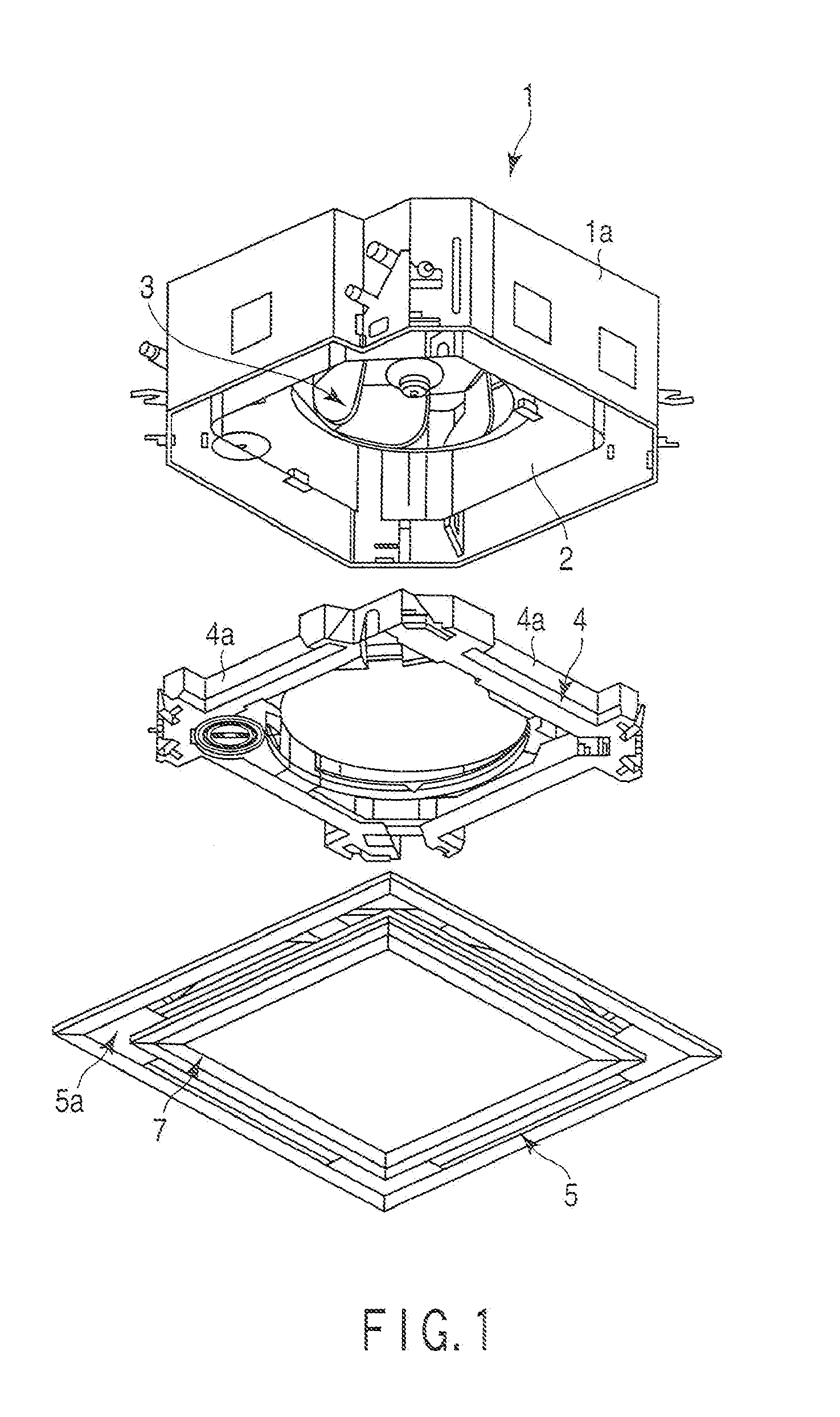

[0038]FIG. 1 is an exploded perspective view of an indoor unit 1 of a ceiling-embedded air conditioner according to one embodiment of the present invention. FIG. 2 shows a state in which the indoor unit 1 is provided in a ceiling 11.

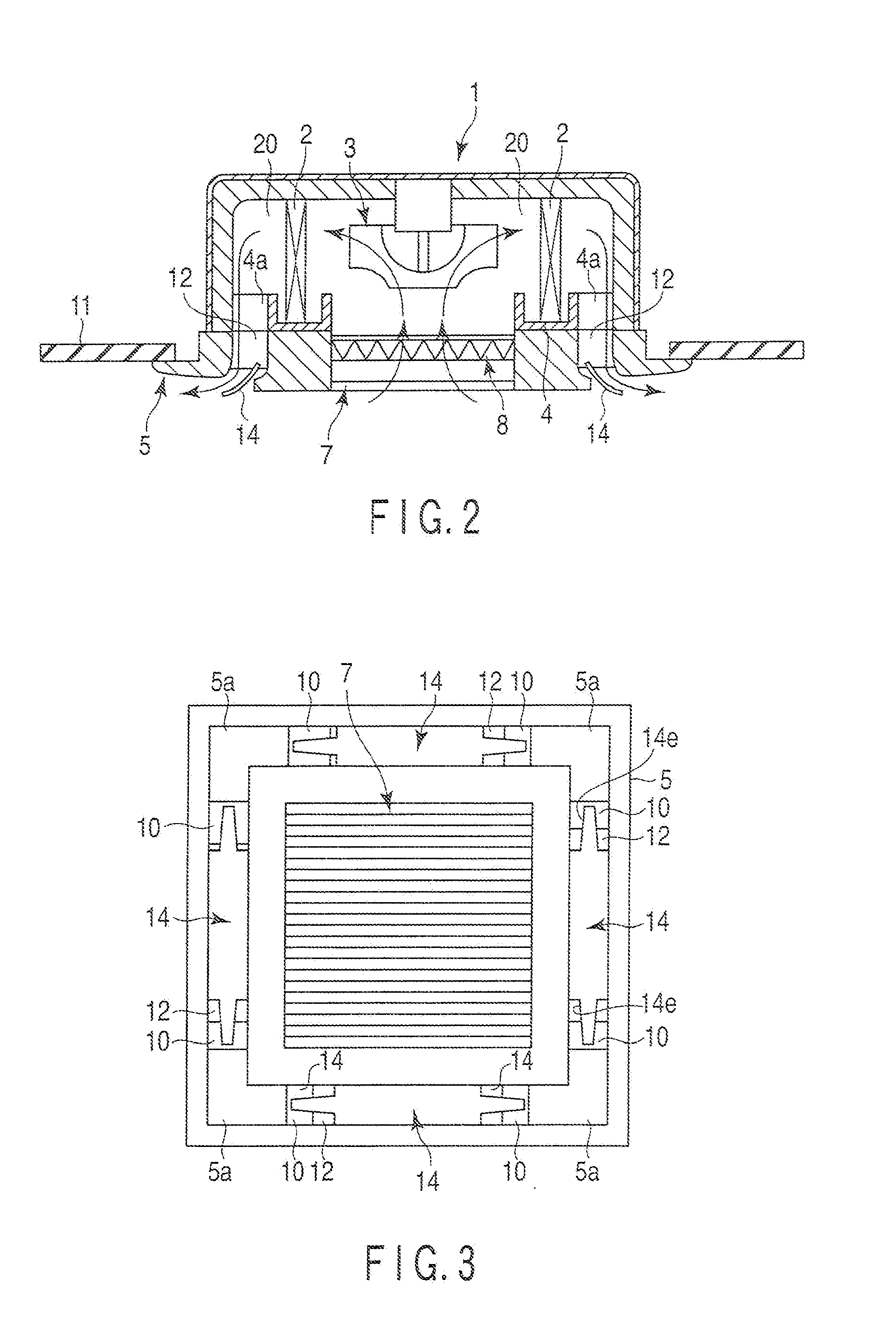

[0039]The indoor unit 1 comprises a casing 1a. A turbo fan 3, serving as an air blower, is provided substantially in the center of the casing 1a. An indoor heat exchange unit 2 surrounds the outer periphery of the turbo fan 3. A drain pan 4 is provided on the lower side of the indoor heat exchange unit 2. A drain pan dent section 4a is formed in each outer side wall of the drain pan. The drain pan dent section 4a communicates with a blow-out port 12 provided in a decorative panel 5 (to be described later) and constitutes part of an air passage 20.

[0040]A decorative panel 5 is provided on the lower side of the casing 1a. A suction grille 7, serving as a suction port, is located substantially in the center of the decorative panel in such a manner that the ...

second embodiment

[0052]FIG. 11 shows the second embodiment of the present invention.

[0053]In the first embodiment described above, the width of the louver 14 gradually decreases, from the central portion 14a to the longitudinal ends 14b. In the second embodiment, the width of a blow-out port 21 increases from the central portion to the longitudinal ends. A louver 22 having a constant width in the longitudinal direction thereof is arranged in the blow-out port 21. A wind-shielding plate 23 configured to prevent the flow-out air from falling down is provided at each end of the blow-out port 21.

[0054]In the second embodiment, when the louver 14 is rotated and kept in the horizontal state (at an angle corresponding to a slightly closed state), the amount of wind coming from the central portion of the blow-out port 21 is decreased, and the amount of wind coming from the end portions is increased. In this manner, the air can be guided laterally and blown out from the end portions of the louver 14, and the...

third embodiment

[0057]FIGS. 13-16 show the third embodiment of the present invention.

[0058]FIG. 13 is a perspective view showing part of a drain pan 4, and FIG. 14 is a sectional view of a side portion of the drain pan 4.

[0059]A pair of projections 25, which are projected upward, are formed on the upper surface of a side wall of the drain pan 4, with a predetermined distance kept away from each other. The paired projections 25 are located in the upper region of the end portions of a blow-out port 12. The upper surface and the inner wall surface of the drain pan 5 are coated with resin 13, and the projections 25 are integrally formed of resin 13.

[0060]Part of the air that has been subjected to heat exchange by the heat exchange unit 2 rises along the inner wall surface of the drain pan 4, as shown in FIG. 14. When the rising air reaches the upper surface of the side wall of the drain pan 4, the air in the center flows in a horizontal direction and enters a drain pan dent section 4a, as indicated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com