Tubular heat dispersing structure

a technology of heat dispersing structure and tubular structure, which is applied in the direction of tubular elements, lighting and heating apparatus, light sources, etc., can solve the problems of reducing the efficiency of heat dispersing in convection manner, baking phenomenon, etc., and achieves enhanced air convection, and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

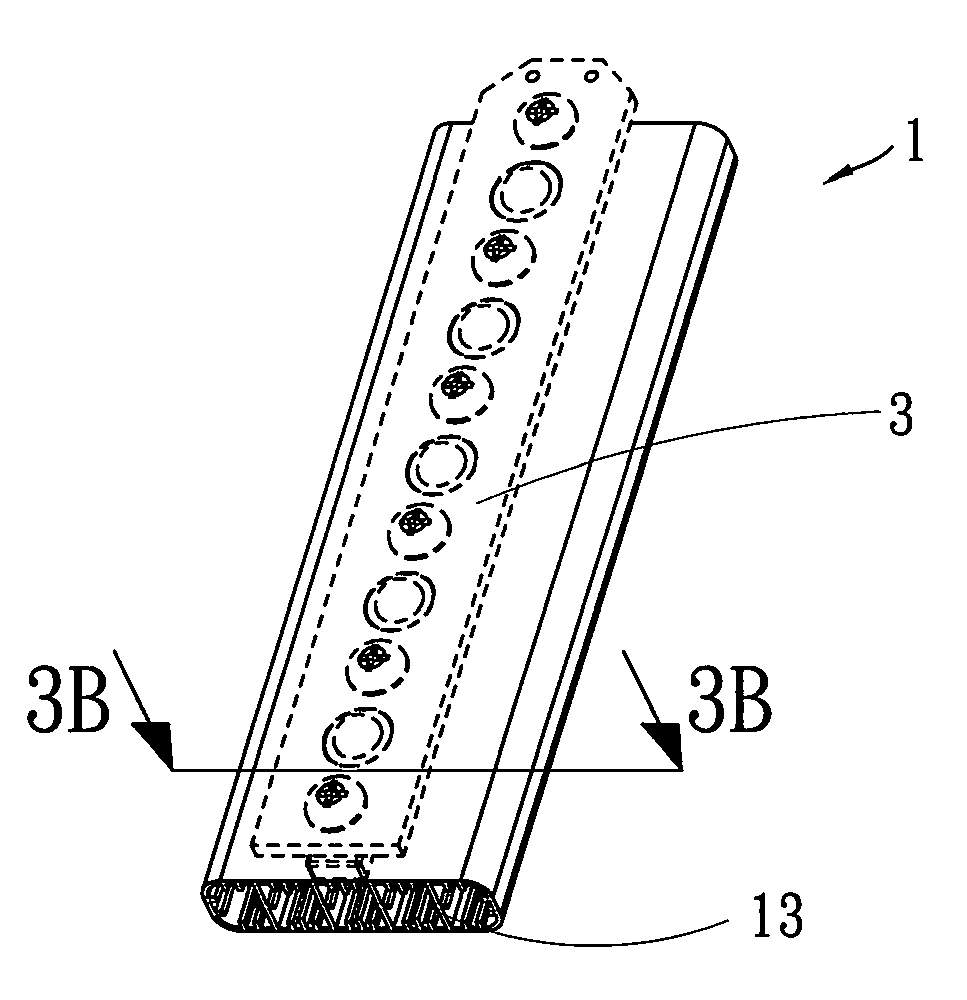

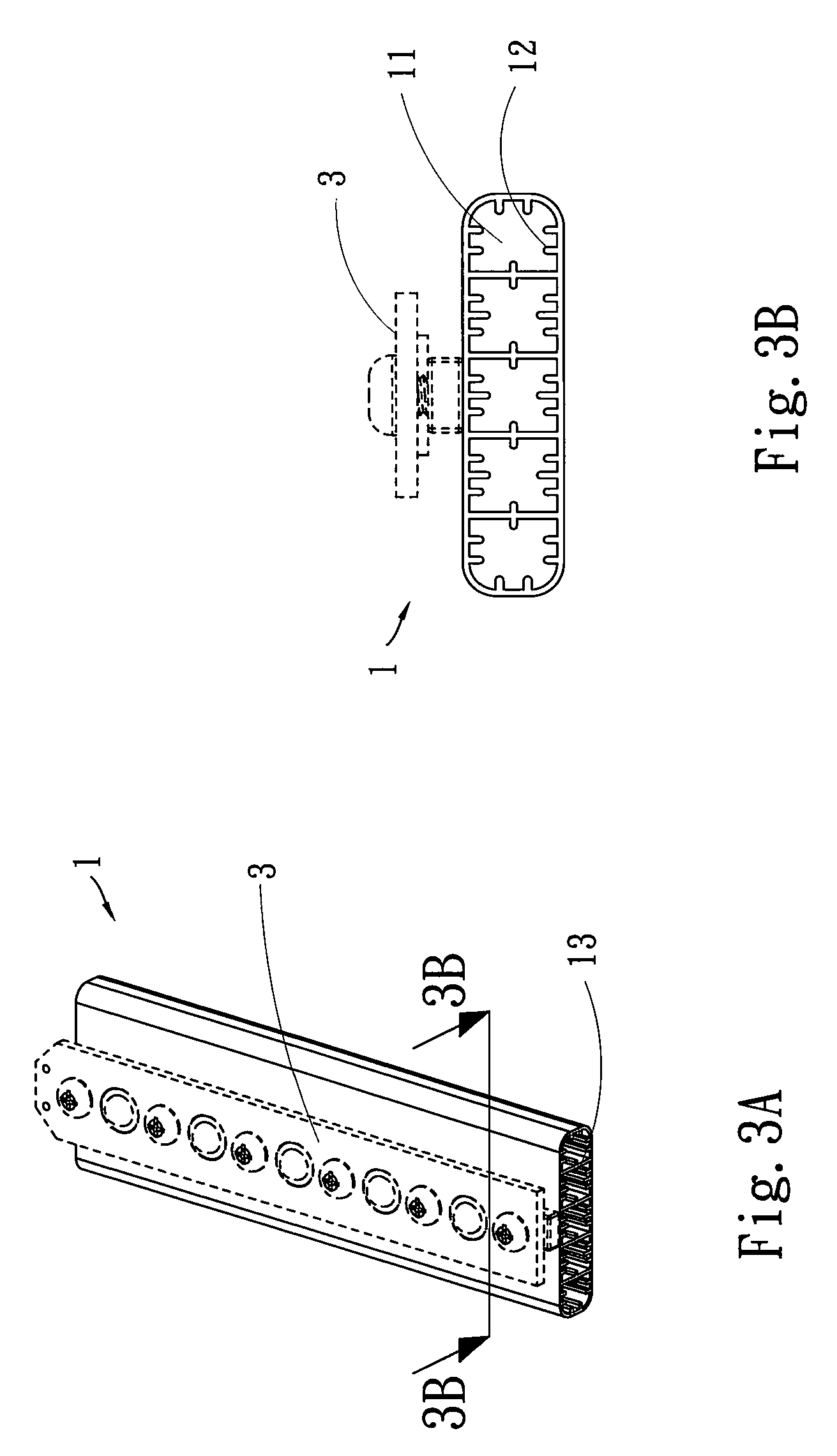

[0035]Please refer to FIGS. 3A, 3B, 4 and 5. When utilizing the tubular heat dispersing structure of the present invention, one or more heat sources and heat conductor 3 are attached to the outer circumference of the heat dispersing body 1, and through air convection, the heat from the heat sources and the heat conductor can be taken away. The present invention includes one or more heat dispersing body 1, which includes one or more channel 11 therein, wherein the channel 11 is a hollow tube with a section of closed geometric figure; plural fins 12 mounted on the inner surface of the channel 11 along the longitudinal direction of the channel 11; and openings 13 respectively mounted at two ends of the channel 11, so as to form the channel 11 passing through the heat dispersing body 1.

[0036]Please refer to FIG. 6 and FIG. 7. When using the tubular heat dispersing structure of the present invention, in accordance with the environment and airflow condition, the heat dispersing body 1 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com