Screen Flow Equalization System

a flow equalization and flow control technology, applied in the direction of sealing/packing, drilling pipes, borehole/well accessories, etc., can solve the problems of icds limiting the ability to circulate gravel packing slurries, other undesirable fluids, and limitations of the integrated design of screens with inflow control devices described, so as to facilitate further drilling, improve gravel deposition, and facilitate circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

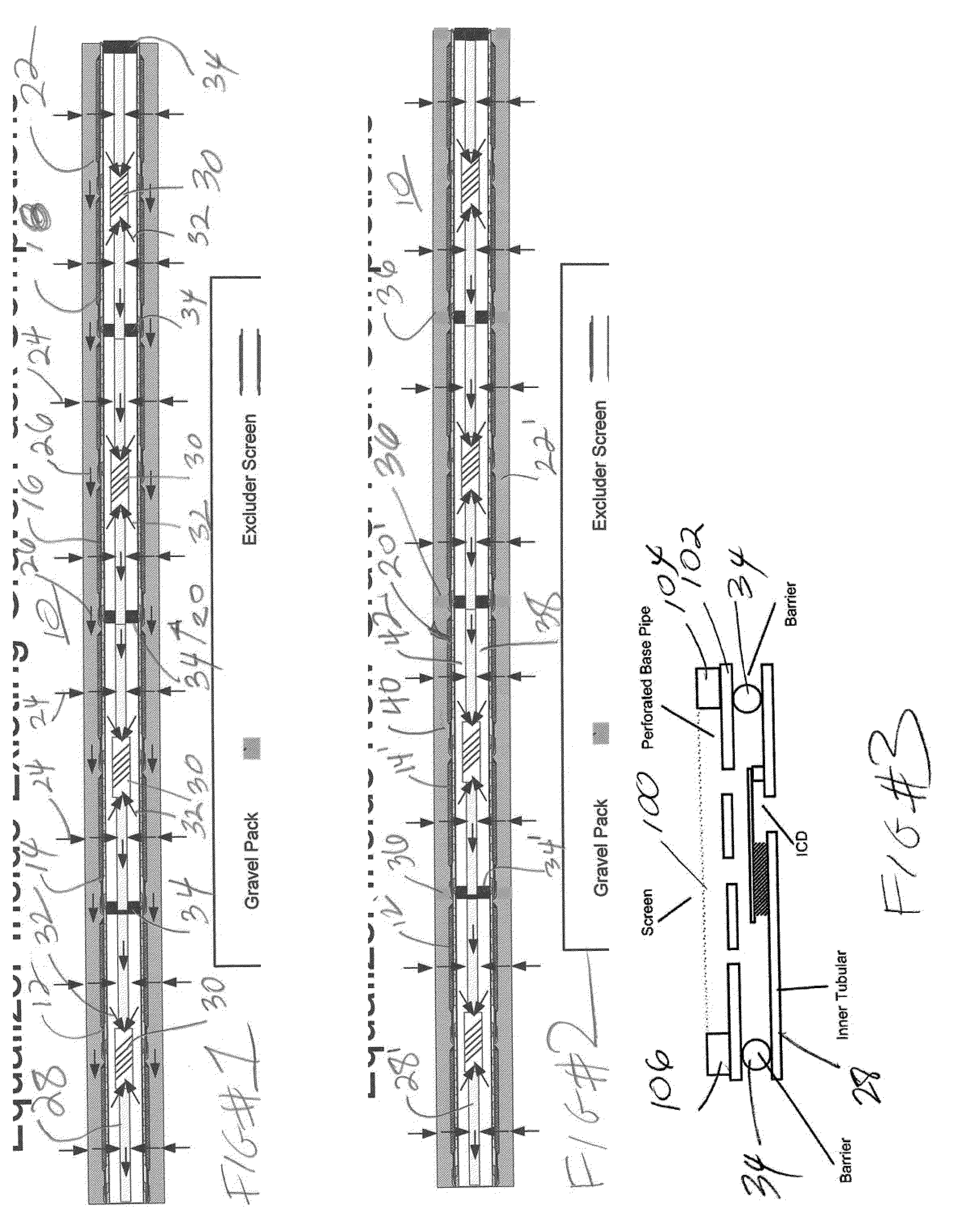

[0022]A pipe joint as used herein includes a section of interest along a continuous string of coiled tubing or other tubular goods and is not intended to be limited to threaded oil country tubular goods (“OCTG”). A stand is intended to mean a given length of interest of a tubular, and is not limited to any particular size or length or configuration of such tubulars. Perforated can include holes or other apertures, or any size and shape or configuration of slots or other openings designed to permit flow therethrough. An inflow control device some examples of which are a tortuous path, an orifice or other opening or path designed to limit or moderate flow at a desired rate of inflow in one zone of interest with respect to another zone of interest.

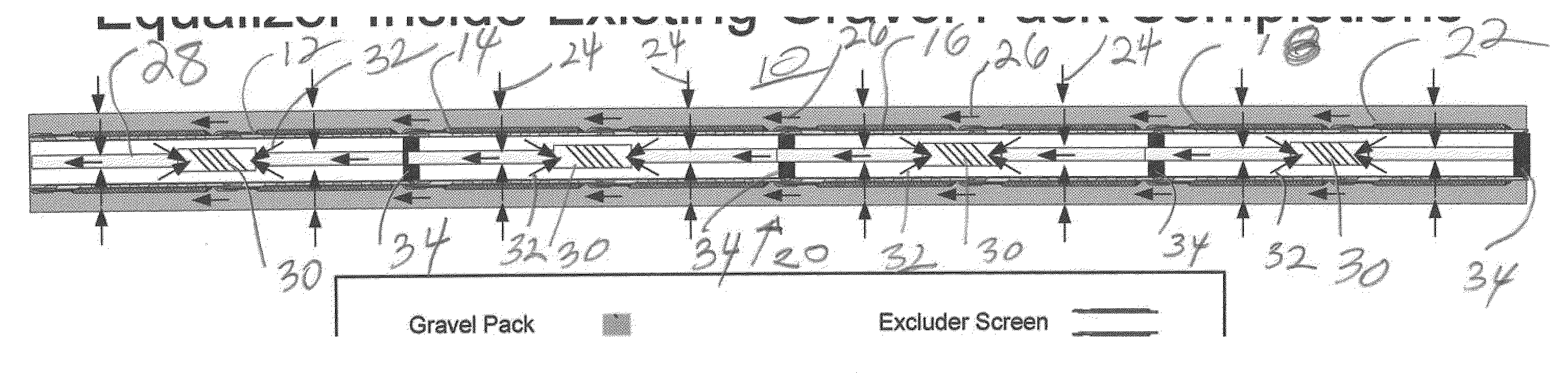

[0023]Referring to FIG. 1 a wellbore 10 which can be open hole or cased hole has a series of screen sections 12, 14, 16 and 18 joined together to make an assembly 20. Although no blank pipe sections are illustrated in assembly 20 it is within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com