Side channel compressor

a compressor and side channel technology, applied in mechanical equipment, non-positive displacement pumps, liquid fuel engines, etc., can solve the problems of annoying side channel compressor frequency, and achieve the effect of facilitating silent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

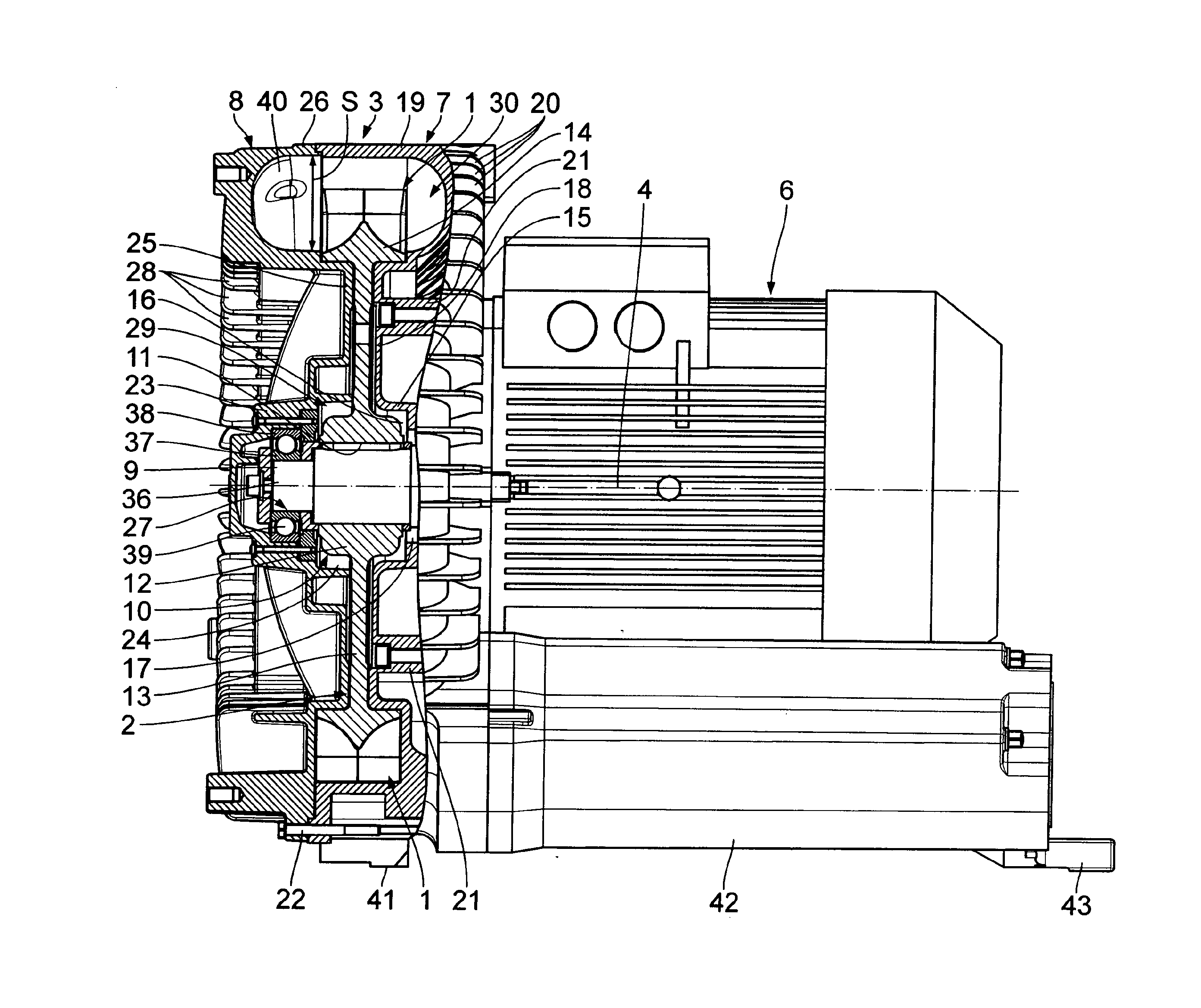

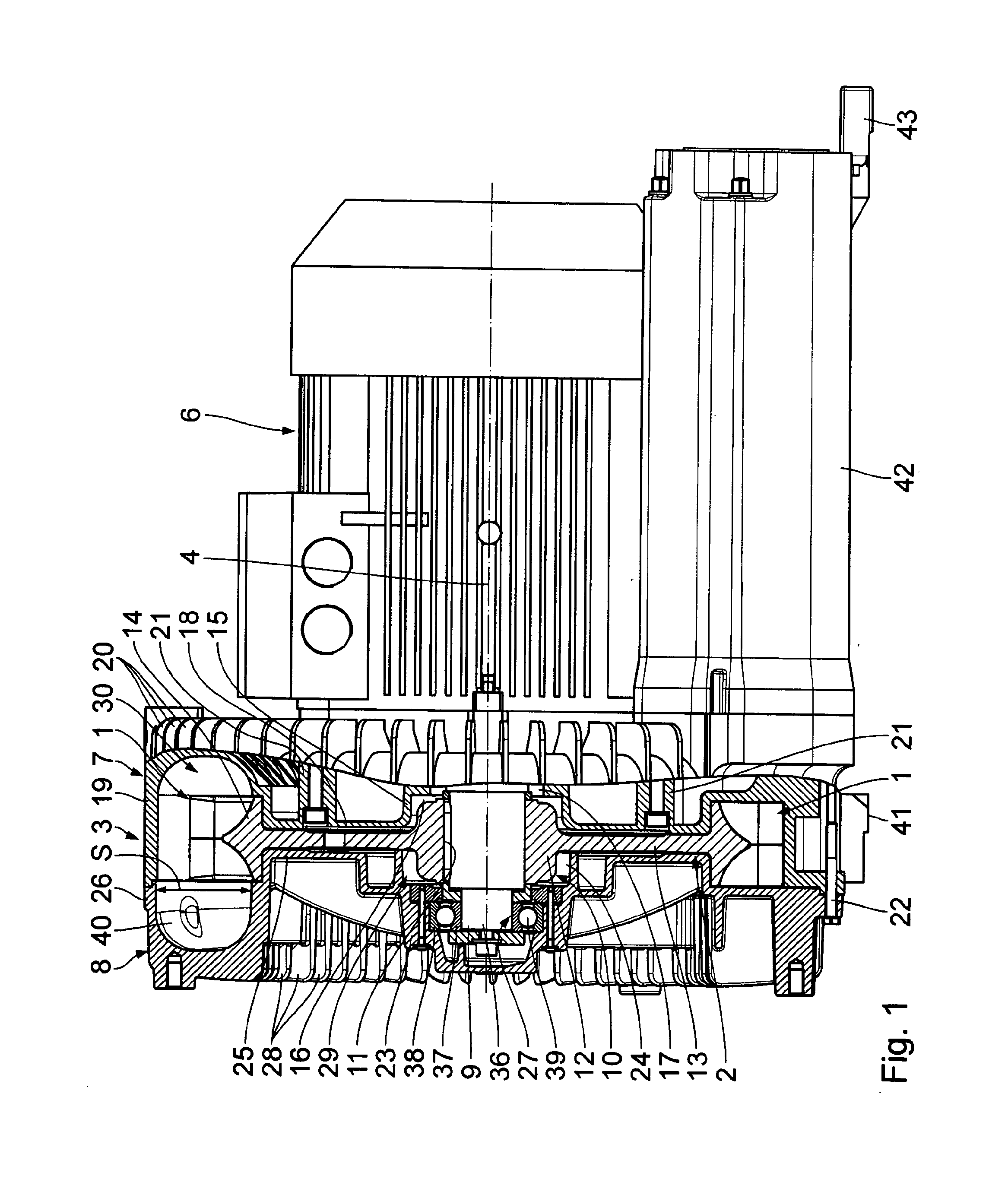

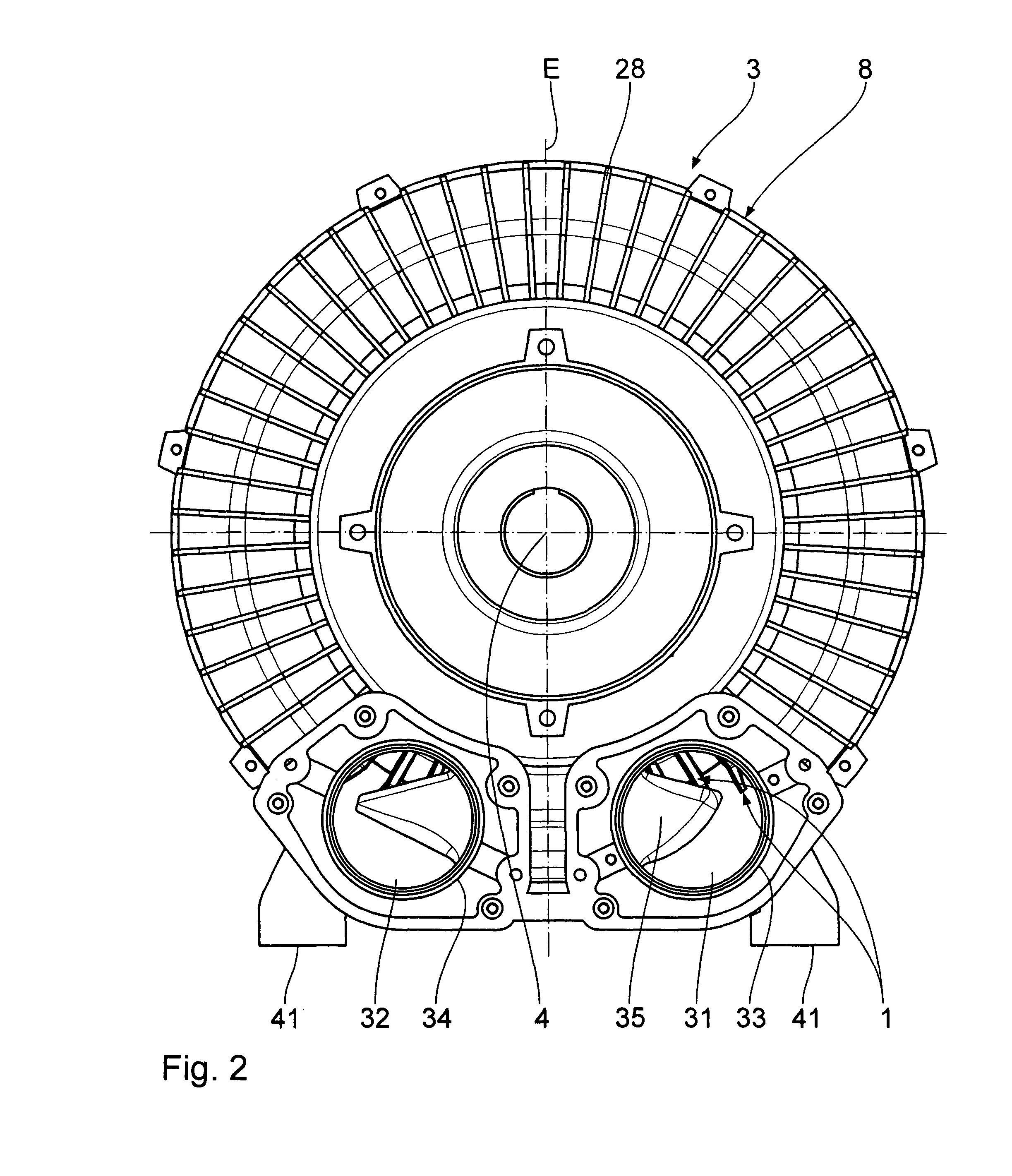

[0026]A side channel compressor shown in FIGS. 1 to 3 for compressing a gas comprises an impeller 2 which is provided with impeller blades 1 and is mounted in a housing 3 for rotation about a horizontal central longitudinal axis 4. A conventional drive 6 serves for rotary drive of the impeller 2 in the direction of the arrow 5. The gas is thus transported through the housing 3 in the direction of the arrow 5 as well.

[0027]The housing 3 comprises a housing body 7 and a demountable housing cover 8 which are joined together according to FIGS. 1 and 2 so as to enclose the impeller 2 comprising the impeller blades 1 which is drivable for rotation and is disposed on a drive shaft 9 for co-rotation therewith.

[0028]The impeller 2 is provided with a single blade ring and is designed like a disk. The impeller 2 comprises an inner impeller hub 10 with a central circular hub bore 11. The impeller hub 10 is formed by an inner hub foot 12 which radially outwardly delimits the hub bore 11, and by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com