Burner for gas boiler

a gas boiler and burner technology, applied in the field of burners for gas boilers, can solve the problems of increasing material costs and manufacturing costs, reducing the life of burners, and difficult to produce combustion, so as to reduce the generation of co, improve the flame holding effect, and reduce the effect of generating co

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Embodiments of a burner for a gas boiler according to the invention, having the above configuration, are described hereafter with reference to the accompanying drawings.

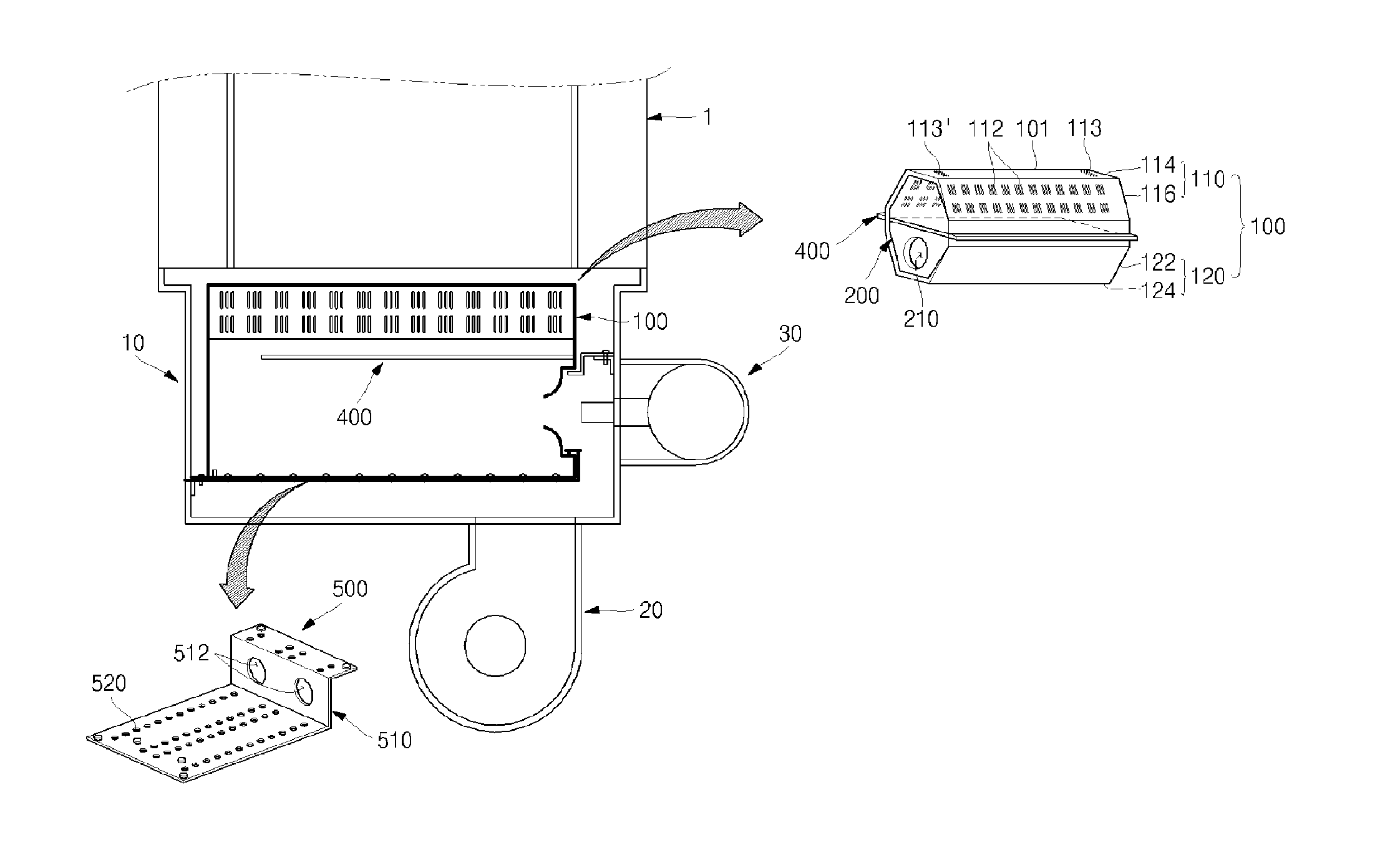

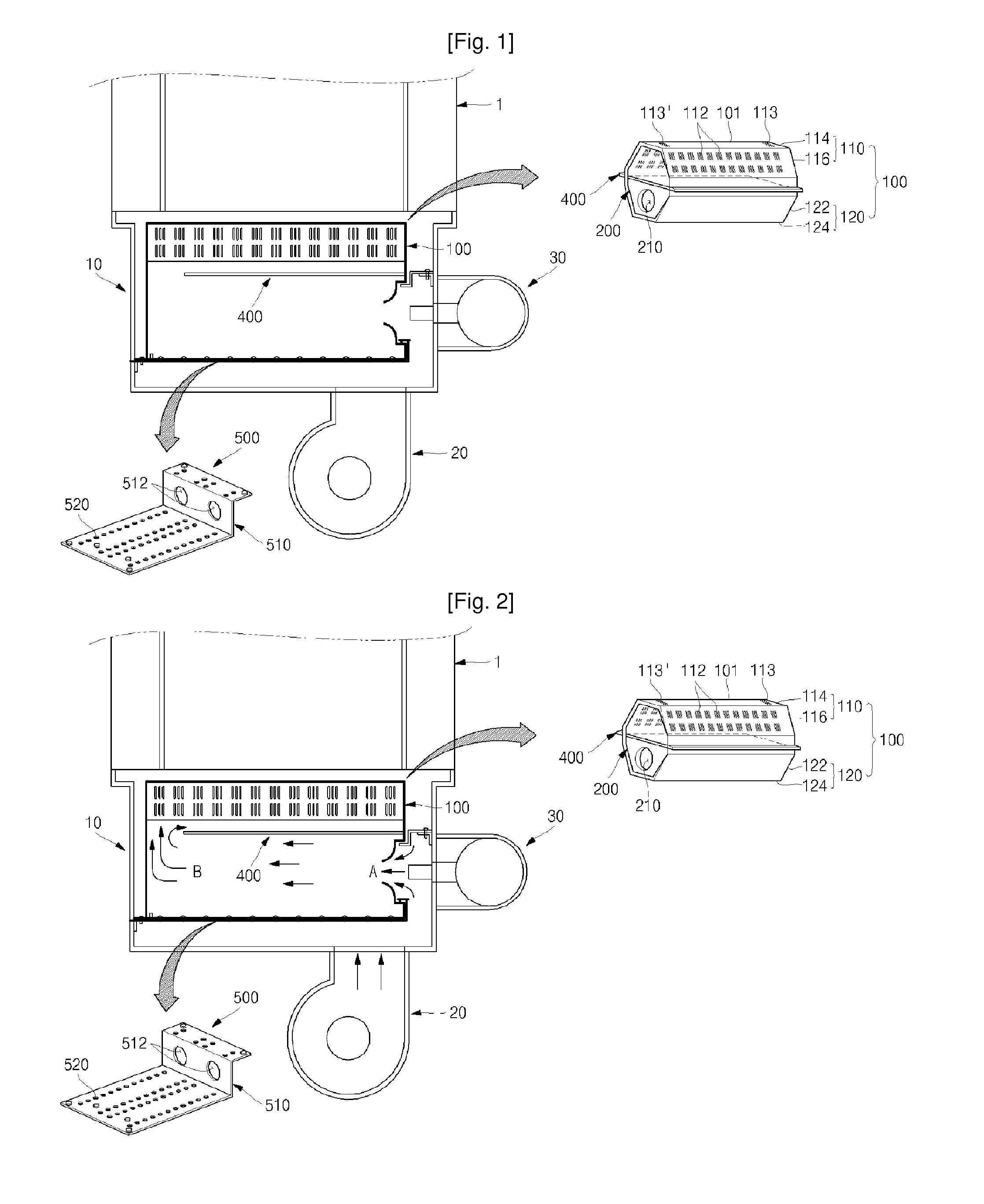

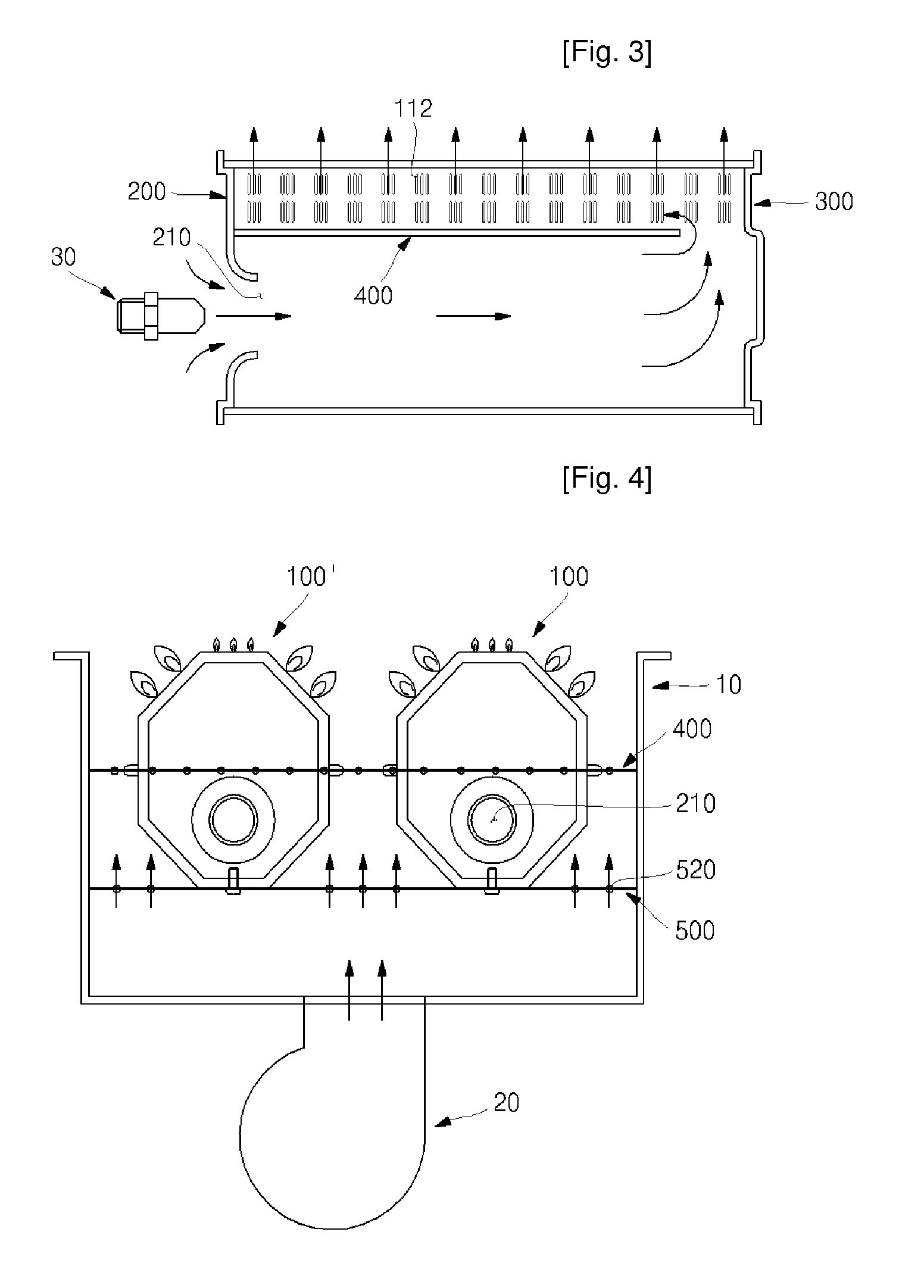

[0022]FIG. 1 is a view illustrating the configuration of a burner for a gas boiler according to the invention and FIGS. 2 to 4 are views illustrating the operation of a burner for a gas boiler according to the invention.

[0023]Referring to FIG. 1, a burner includes: a casing 10 that has a space inside; a fan 20 that is connected to the lower side of the casing 10 and supplies the external air into the casing 10; a nozzle unit 30 that is connected to a side of the casing 10 and injects gas at high speed through the front end disposed inside the casing 10; and a burner main body 100 that is disposed from a predetermined distance from the bottom of the casing 10 and has a burner upper plate 110 having main fire holes 112 formed at regular distances at both sides in the longitudinal direction of a burner body 101 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com