Cam driving device and processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

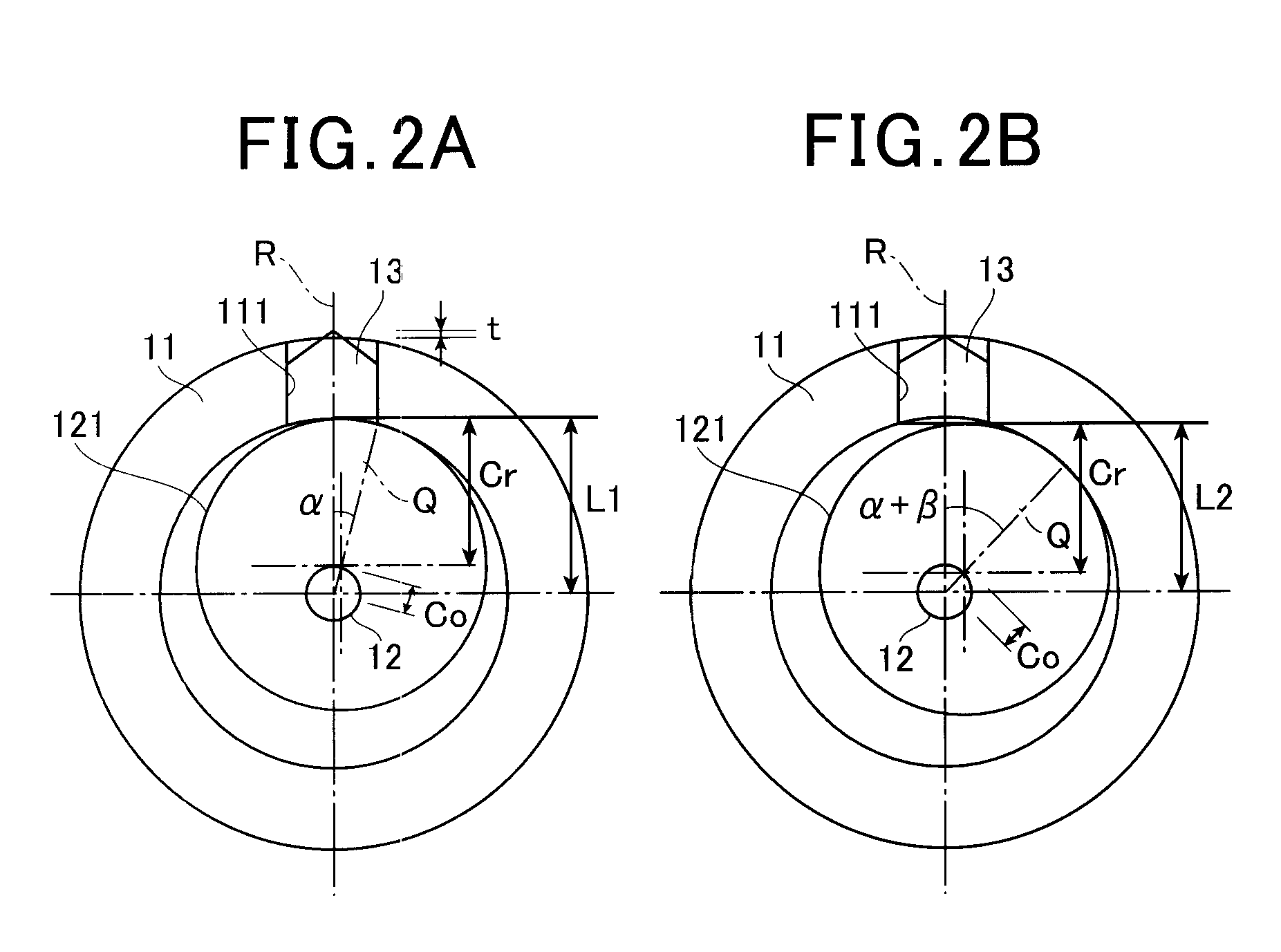

[0038]An embodiment according to the present invention will be described with reference to the accompanying drawings.

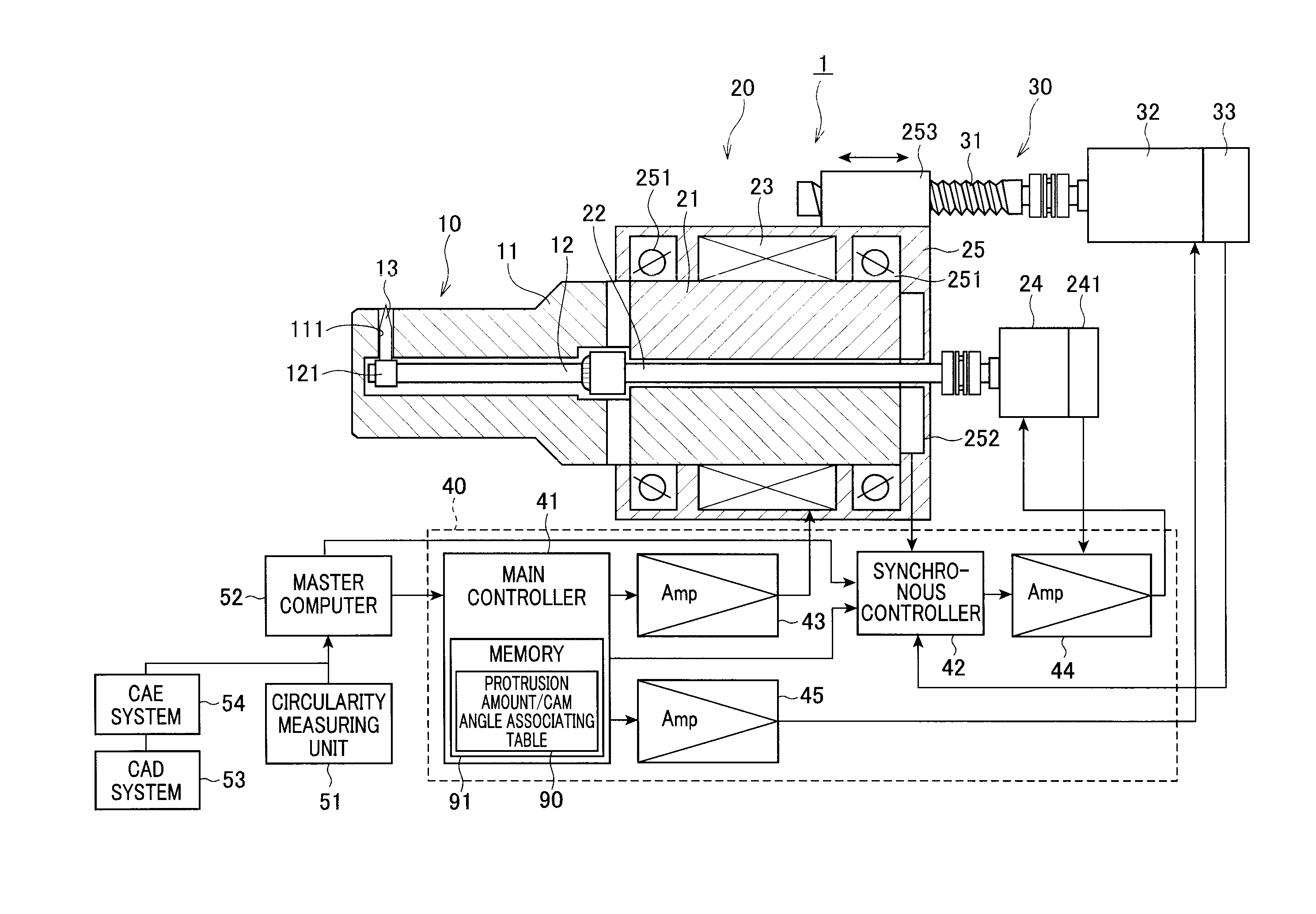

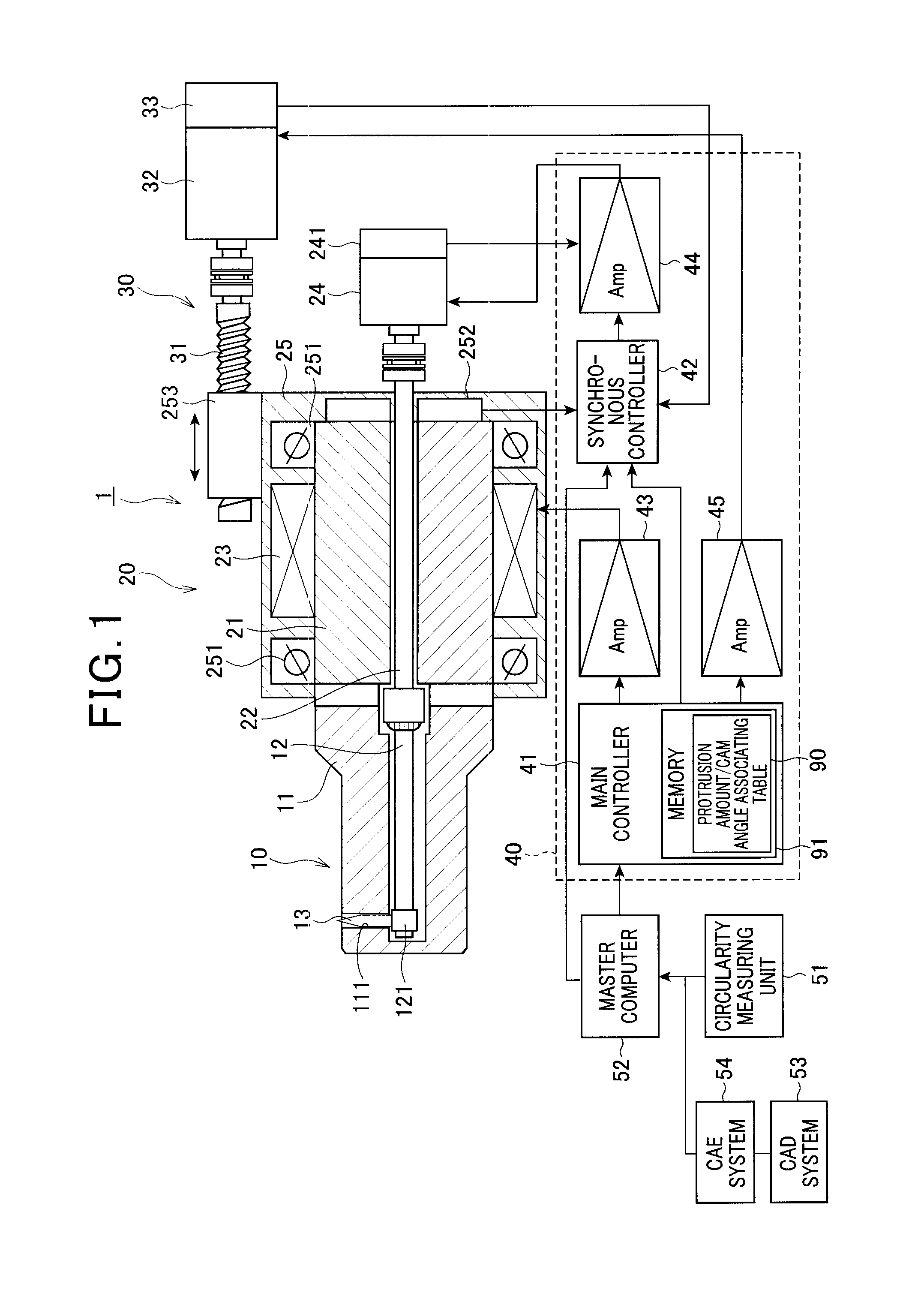

[0039]FIG. 1 is a diagram showing the construction of a non-circular bore processing device 1 according to an embodiment of the preset invention.

[0040]The non-circular bore processing device 1 inserts a processing head 10 into a bore of a cylinder block of a vehicle engine as a work and performs boring processing. The non-circular bore processing device 1 comprises a rotational driving mechanism 20 for rotating the processing head 10, a reciprocating mechanism 30 for advancing and retracting the rotational driving mechanism 20, a controller (cam driving device) 40 for controlling the above parts, a circularity measuring unit 51 for measuring the internal shape of the bore of the work, and a master (superordinate) computer 52 analyzing the measurement result of the circularity measuring unit 51 and outputting an analysis result to the controller 40.

[0041]The rotational...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap