Apparatus and method for compensating for stress deformation in a press

a technology of stress deformation and apparatus, which is applied in the direction of presses, manufacturing tools, shaping tools, etc., can solve the problems of extreme stress, deformation of hydraulic press parts, and so on, and achieve the effect of uniform compression depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

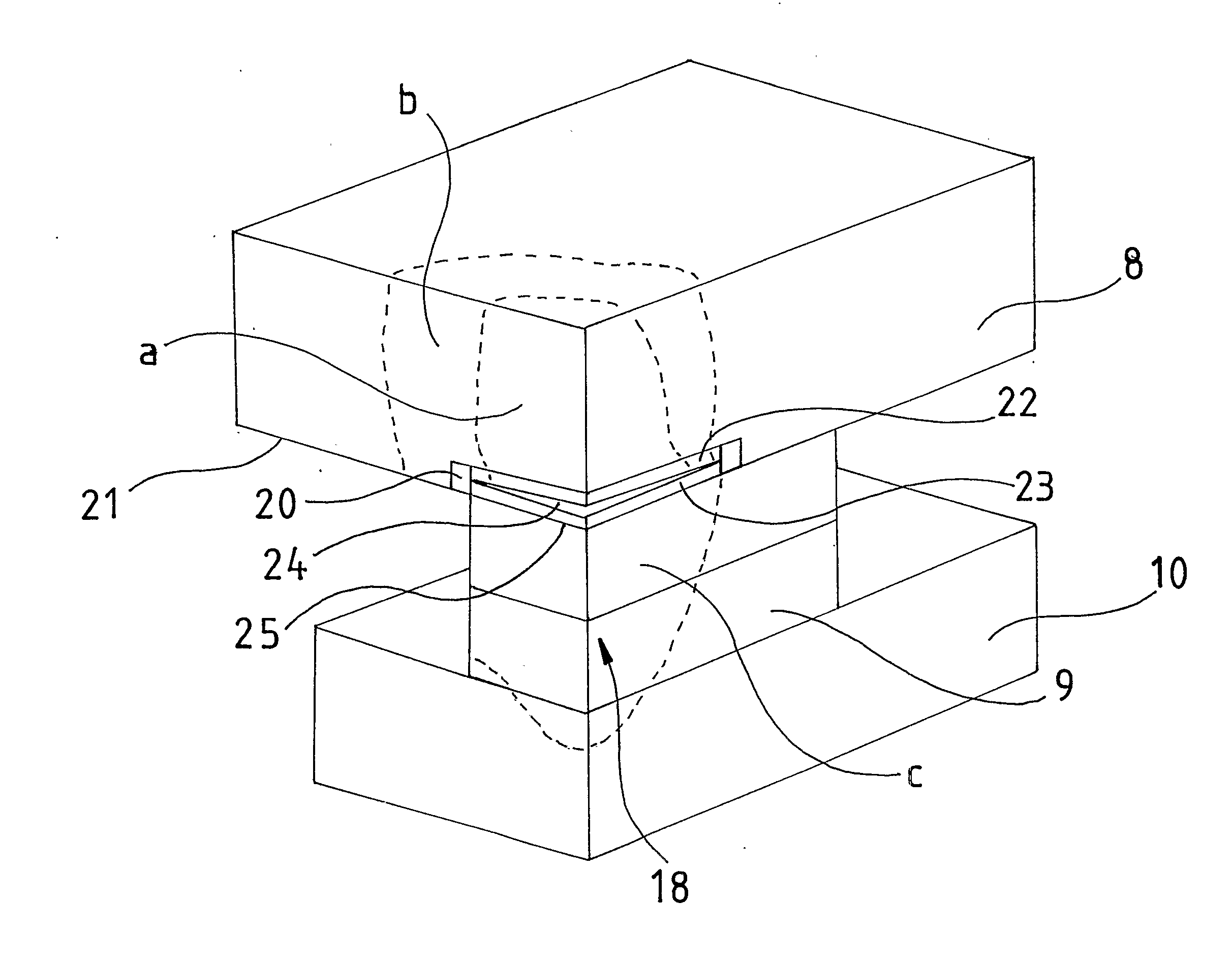

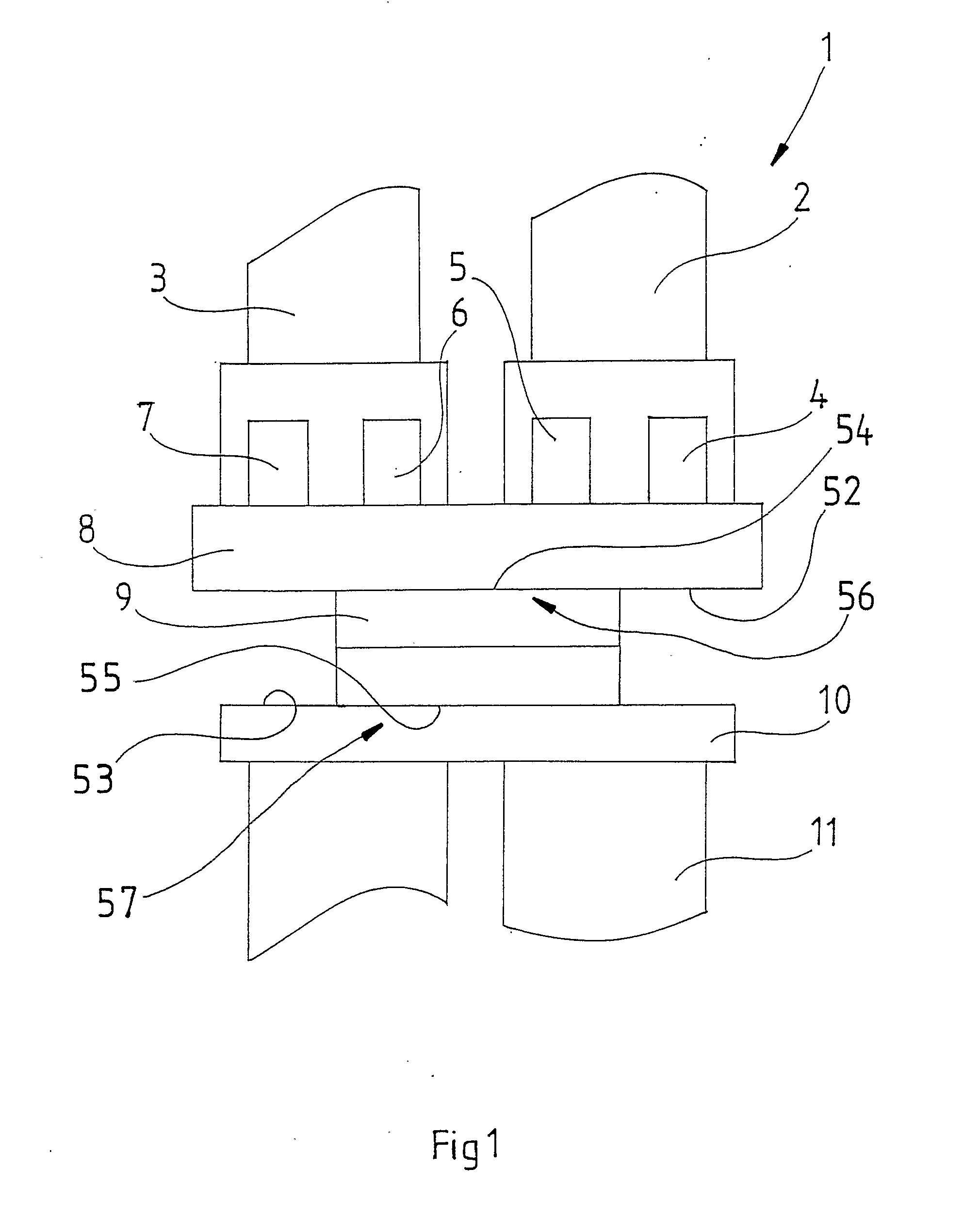

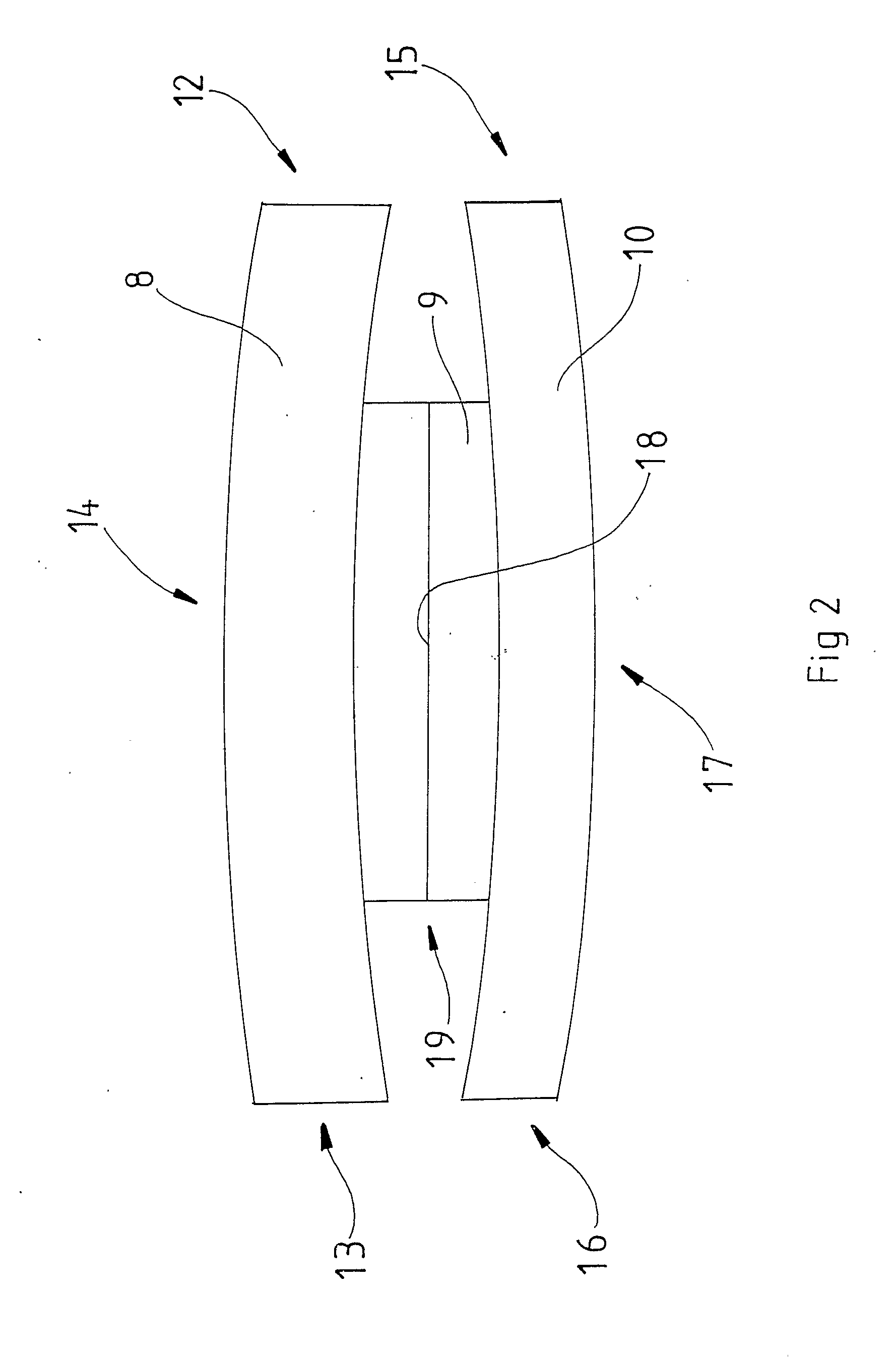

[0024]FIG. 1 shows a hydraulic press 1 in which two large press cylinders 2, 3 together with four smaller press cylinders 4, 5, 6 and 7 act on a slide 8. Beneath the slide, a tool 9 is disposed which rests on a work table 10. The lower part 11 of the hydraulic press is disposed beneath the work table 10.

[0025]The tool 9 is of dual construction and has an upper part which is fixed in the slide 8 and a lower part which is fixed on the work table 10.

[0026]The illustrated type of hydraulic press 1 operates as follows. Between the slide 8 and the work table 10, the tool 9 is positioned. In this tool 9, there is placed a work piece (blank) which is to be formed by this tool. When the work piece is in place in the tool 9, the slide 8 presses the tool 9 against the work table 10 with the aid of the press cylinders 2, 3, 4, 5, 6 and 7. Once these press cylinders have acted for a given time interval which is sufficiently long for the work piece placed in the tool 9 to have achieved the desire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressing pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| STRESS DEFORMATIONS | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com