Vibration control technology and interface for computer printers and scanners

a computer printer and scanner technology, applied in the field of vibration suppression in computer printers and scanners, to achieve the effect of increasing the “speed” of the machine, reducing the settle time, and increasing the acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

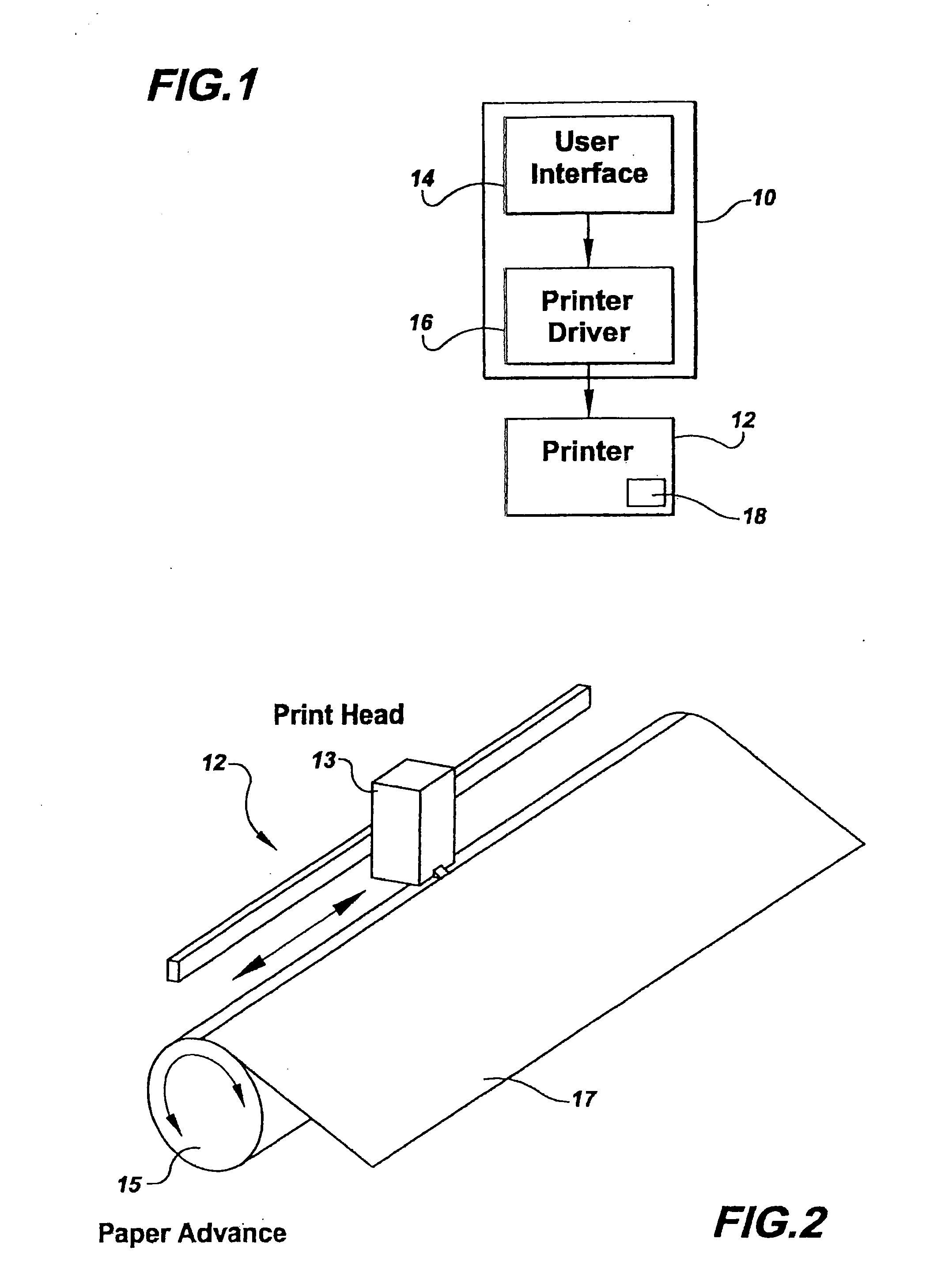

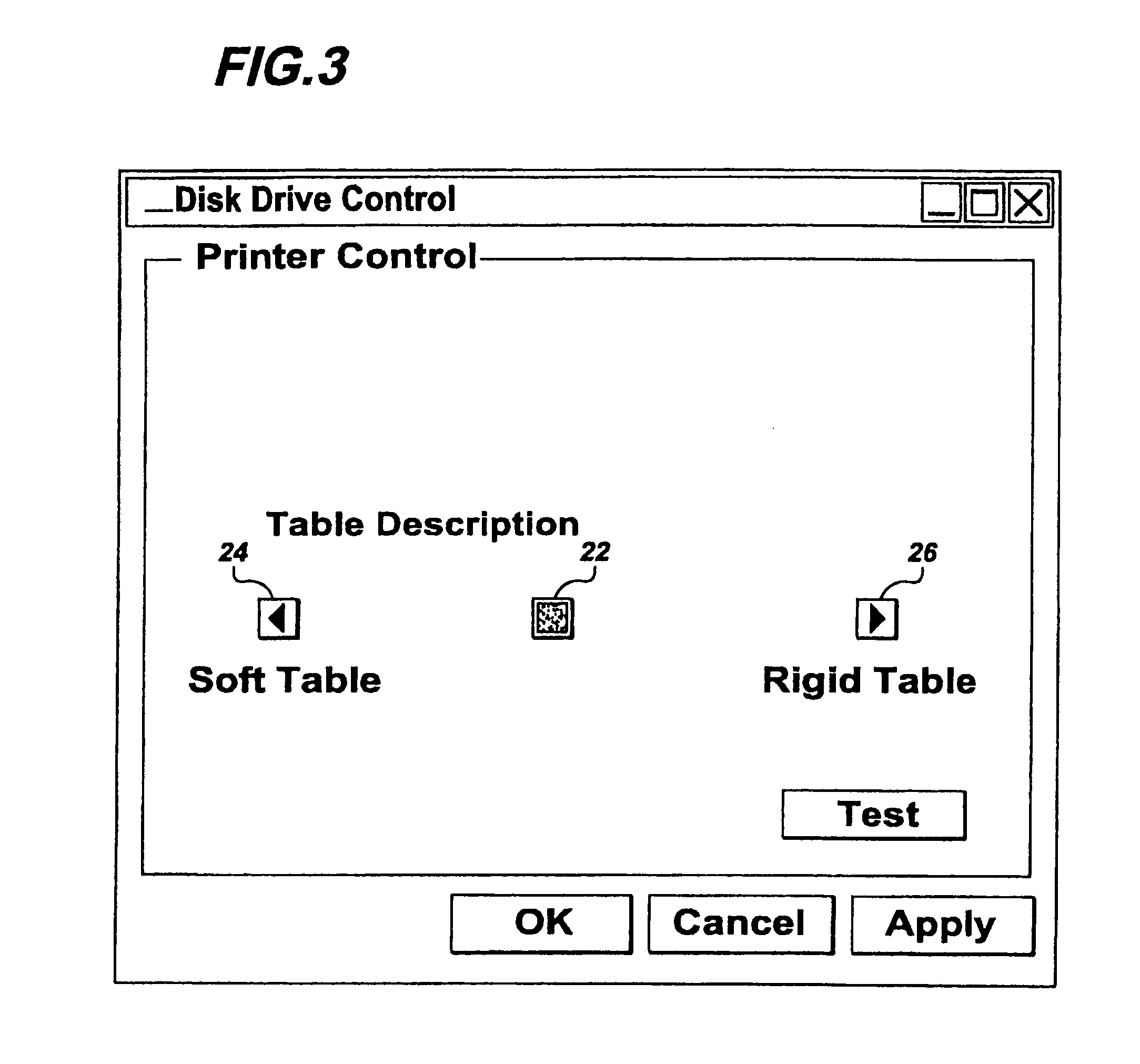

[0022]The exemplary description provided below is in terms of a printer. It is fully recognized that the same description would apply to scanners or any other computerized reproduction device that works in a similar fashion. FIG. 1 shows a block diagram of a computer 10 and printer 12. The user specifies information about the mode of operation of the printer12 (i.e. “Quick” or “Quiet”). The user does this through a command or user interface 14. The interface 14 could be built into a printer driver 16 and appear on a print dialog box. Alternatively, the interface 14 could be a stand-alone configuration program that the user uses to periodically (or even once) change the printer's mode of operation. Alternatively, the interface 14 could be part of the printer 12 installation program.

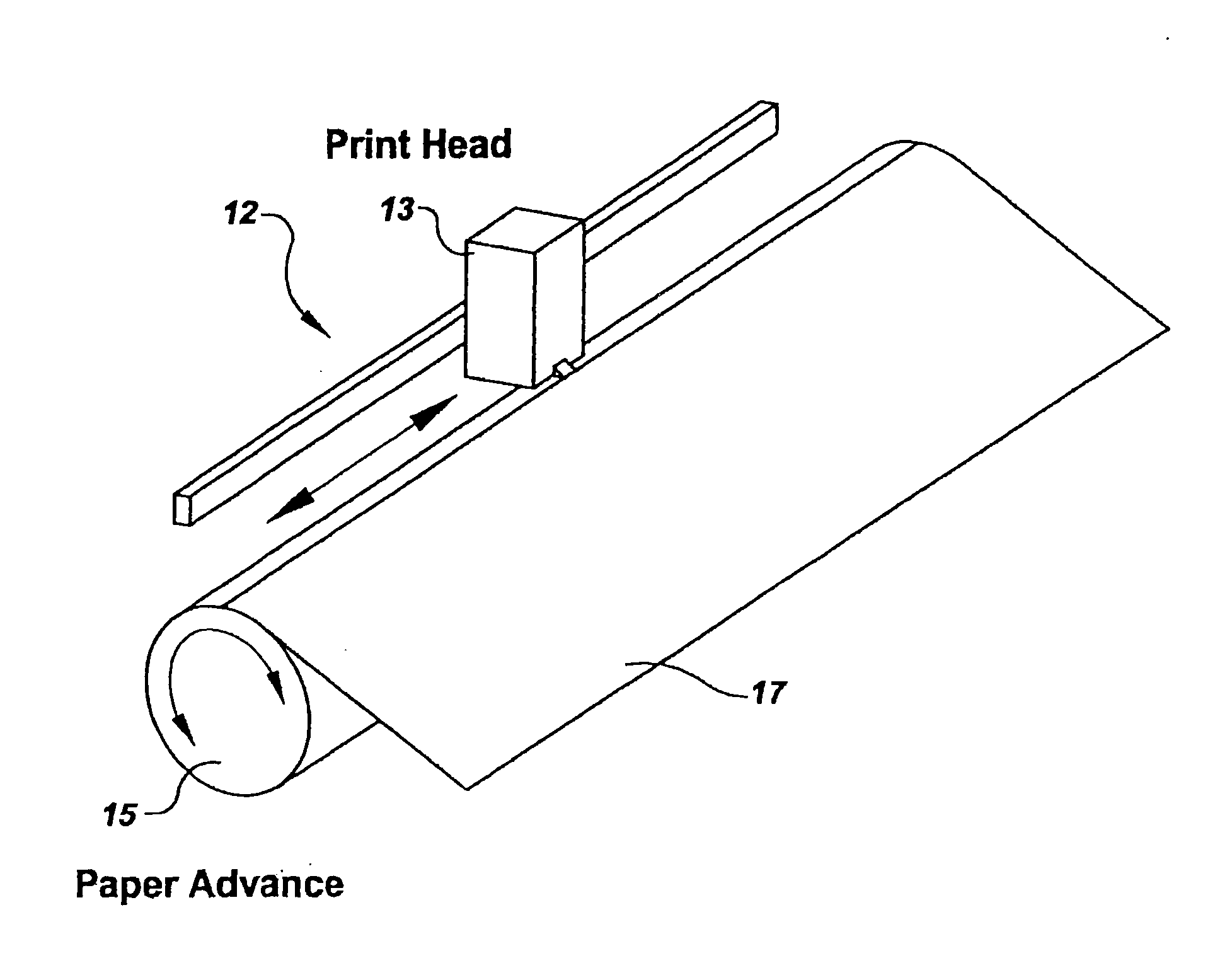

[0023]With reference to FIG. 2, the printer 12 includes a print head 13 that is mounted for lateral translation. The printer 12 also includes a paper feed mechanism 15 that advances paper 17.

[0024]Once a u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com