Tie foundation for a railway tie

a technology for tie foundations and railways, applied in the direction of railway tracks, lamination, track maintenance, etc., can solve the problems of insufficient resistance of tie foundations and early destruction of tie foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

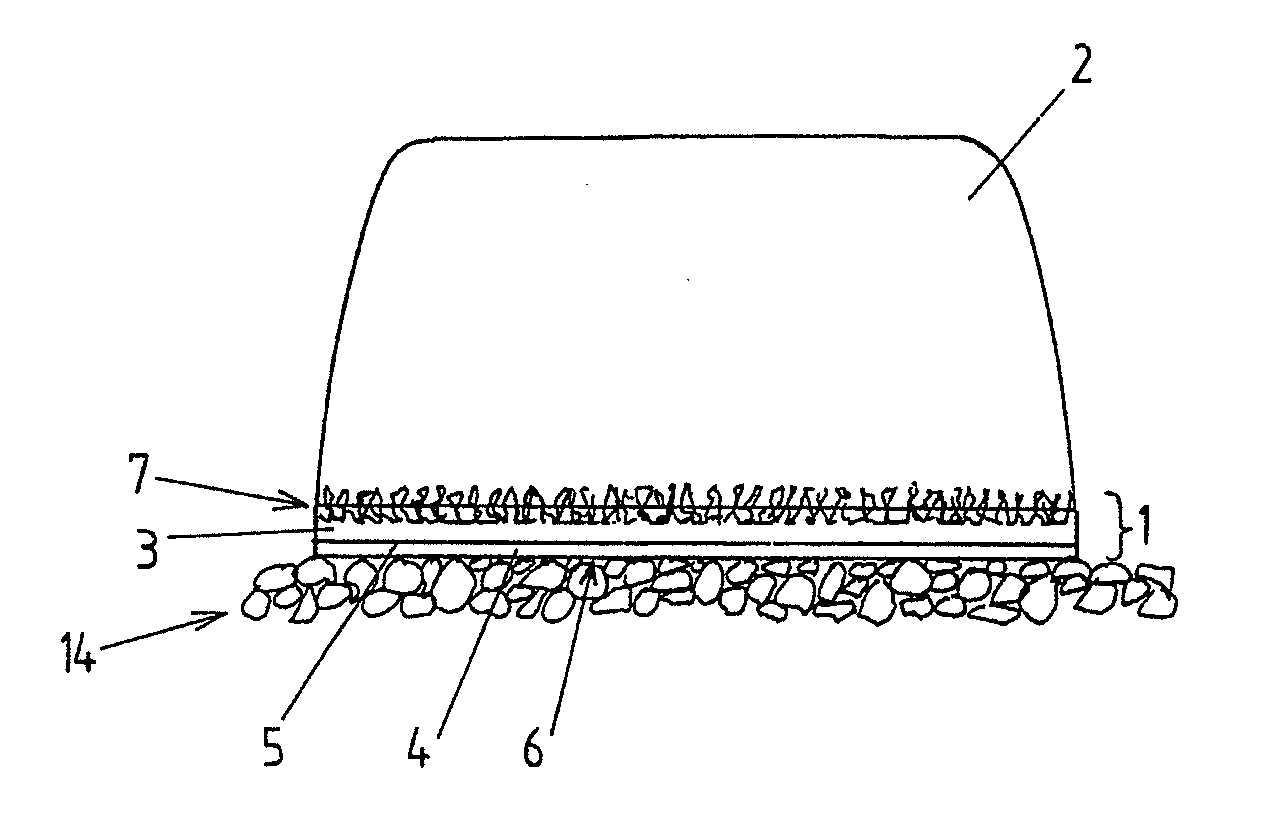

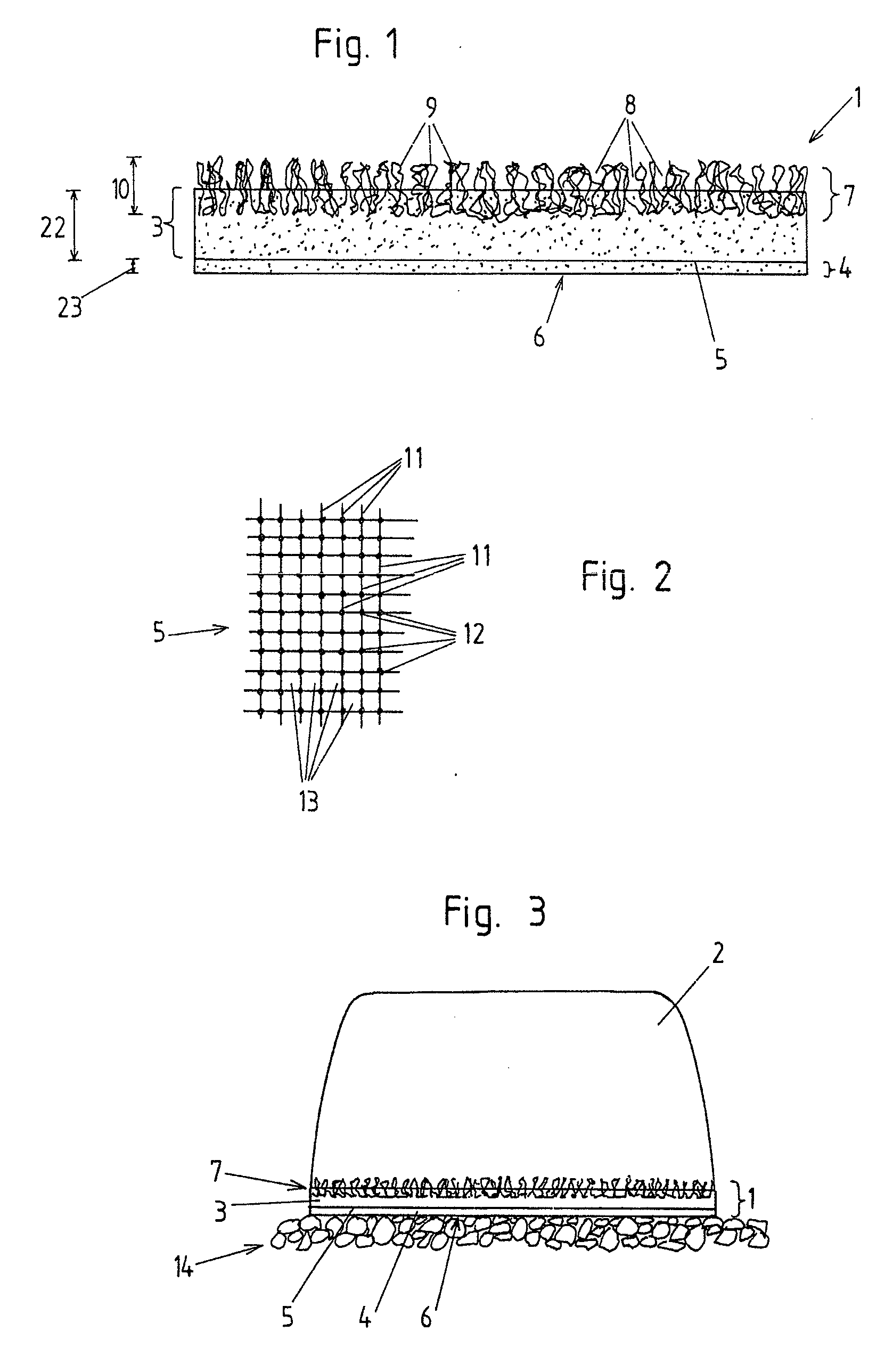

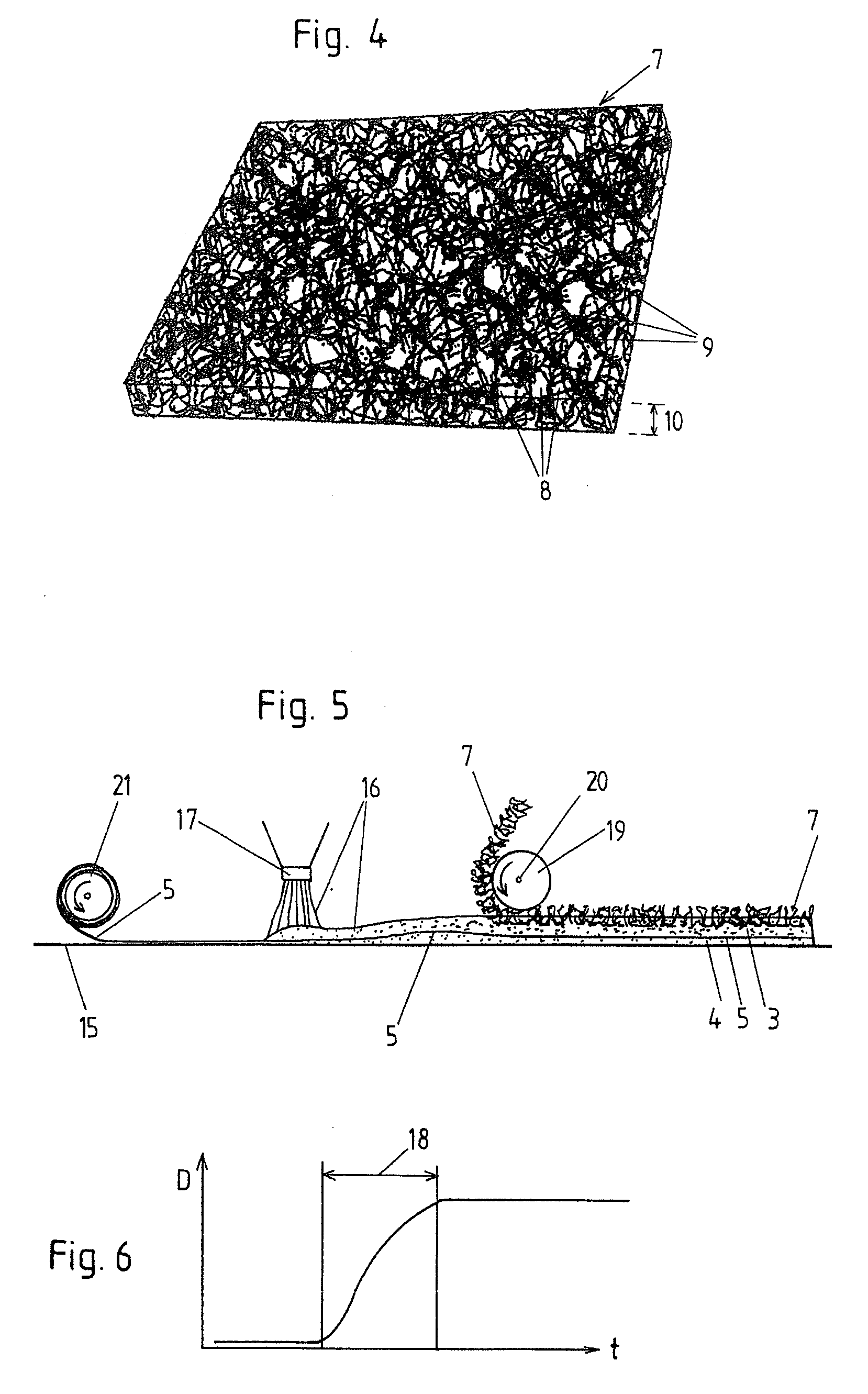

[0034]In a preferred exemplary embodiment according to FIG. 1, the reinforcement layer 5 is arranged between the first elastic layer 3 and the second elastic layer 4 of the tie foundation 1. Here, the second elastic layer 4 forms the lower exterior surface 6 of the tie foundation 1, i.e. in the operating position facing away from the railway tie and / or opposite thereto. On the opposite side, i.e. the one pointing towards the railway tie 2 in the operational position, the tie foundation 1 is provided with the connection layer 7, which in the exemplary embodiment shown here is embedded in the first elastic layer 3. The connecting layer 7 forms a spatially expanded grid made from threads 9. The clear spaces 8 are formed between the threads 9, into which the material of the railway tie can penetrate in the sense of a form-fitting, material-fitting, or fabric-fitting connection. In order to fasten it to the first layer 3, the connection layer 7 is embedded by approx. 40% of its thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com