Composite downhole tool with reduced slip volume

a technology of tooling and slippage, applied in the direction of fluid removal, sealing/packing, borehole/well accessories, etc., can solve the problems of metal components that require numerous trips in and out, tool damage, and longer milling operation, so as to reduce the volume of metal, improve the uniformity of fracturing, and increase the speed of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

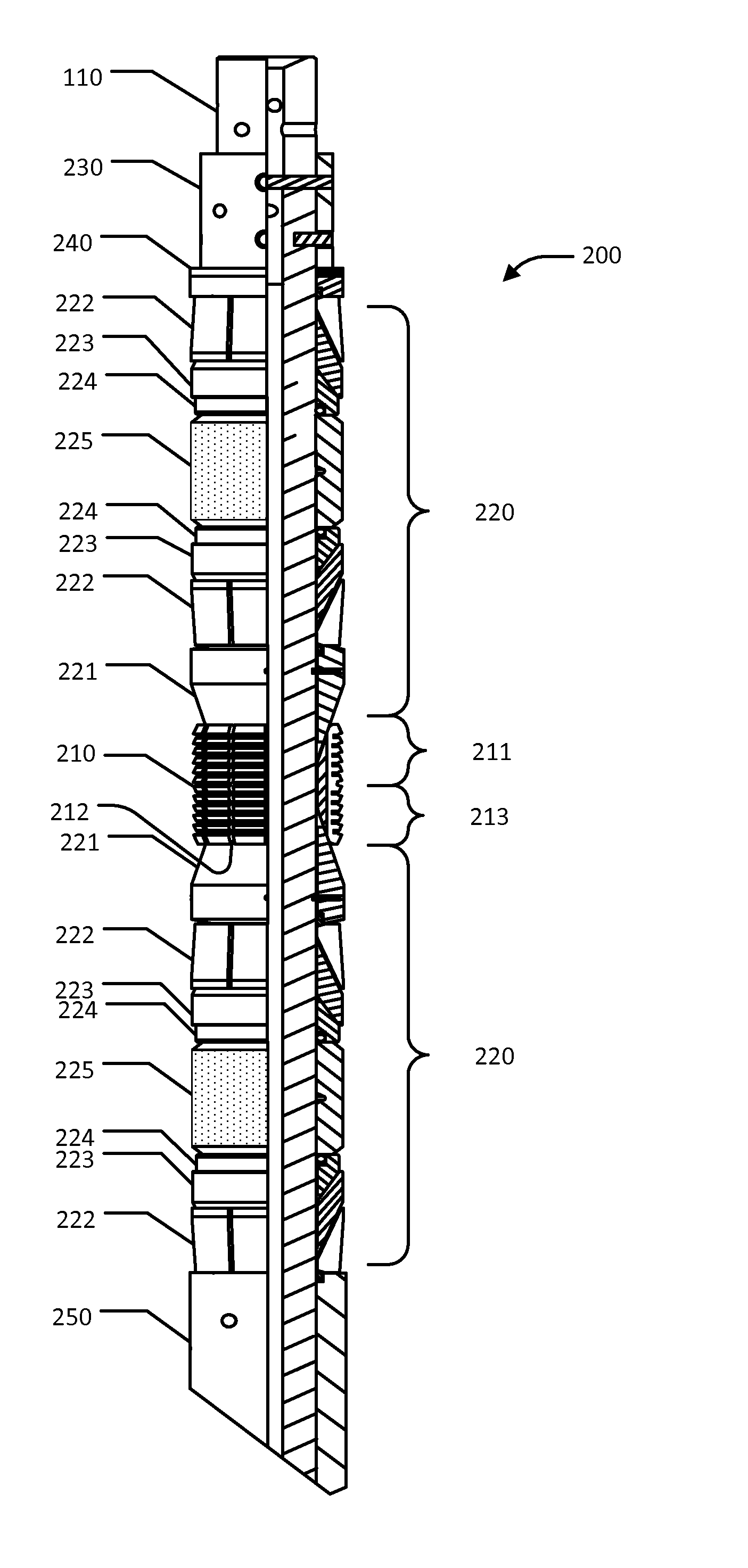

[0015]FIG. 1 is a cutaway view of a conventional bridge plug 100 according to the prior art. The bridge plug 100 comprises a mandrel 110, about which are disposed various elements, which are typically formed of metal, but can be made of a composite material, such as is described in U.S. Pat. No. 7,124,831, which is incorporated herein by reference in its entirety for all purposes. Even when most of the bridge plug 100 is made of composite materials, the two slips 130 are typically made of metal, such as a ductile cast iron.

[0016]As shown in FIG. 1, a sealing member 120 and other related elements 125 are disposed about the mandrel 110. Axial force through the slips 130 and the other elements 125 compress the sealing member 120, causing it to expand and to seal with the surrounding tubular (not shown). The two slips 130, oriented opposite to each other, expand to engage with the surrounding tubular and help retain the downhole tool in place in the wellbore. Boost forces from the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com