Valve assembly, repair kit, and method for salvaging an aerosol container

a valve assembly and aerosol container technology, applied in liquid handling, instruments, volume meters, etc., can solve problems such as inability to refill, and achieve the effect of enhancing the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

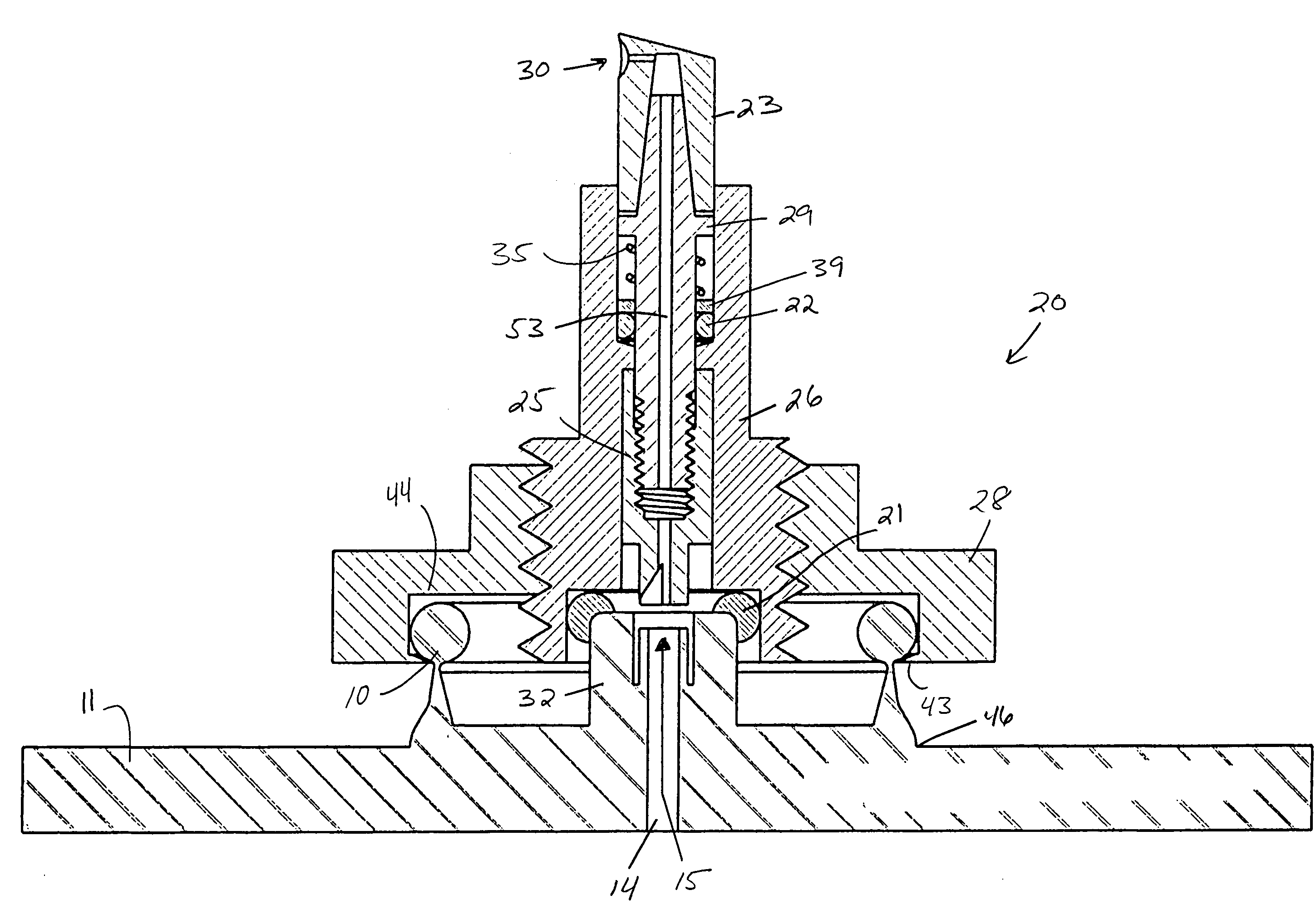

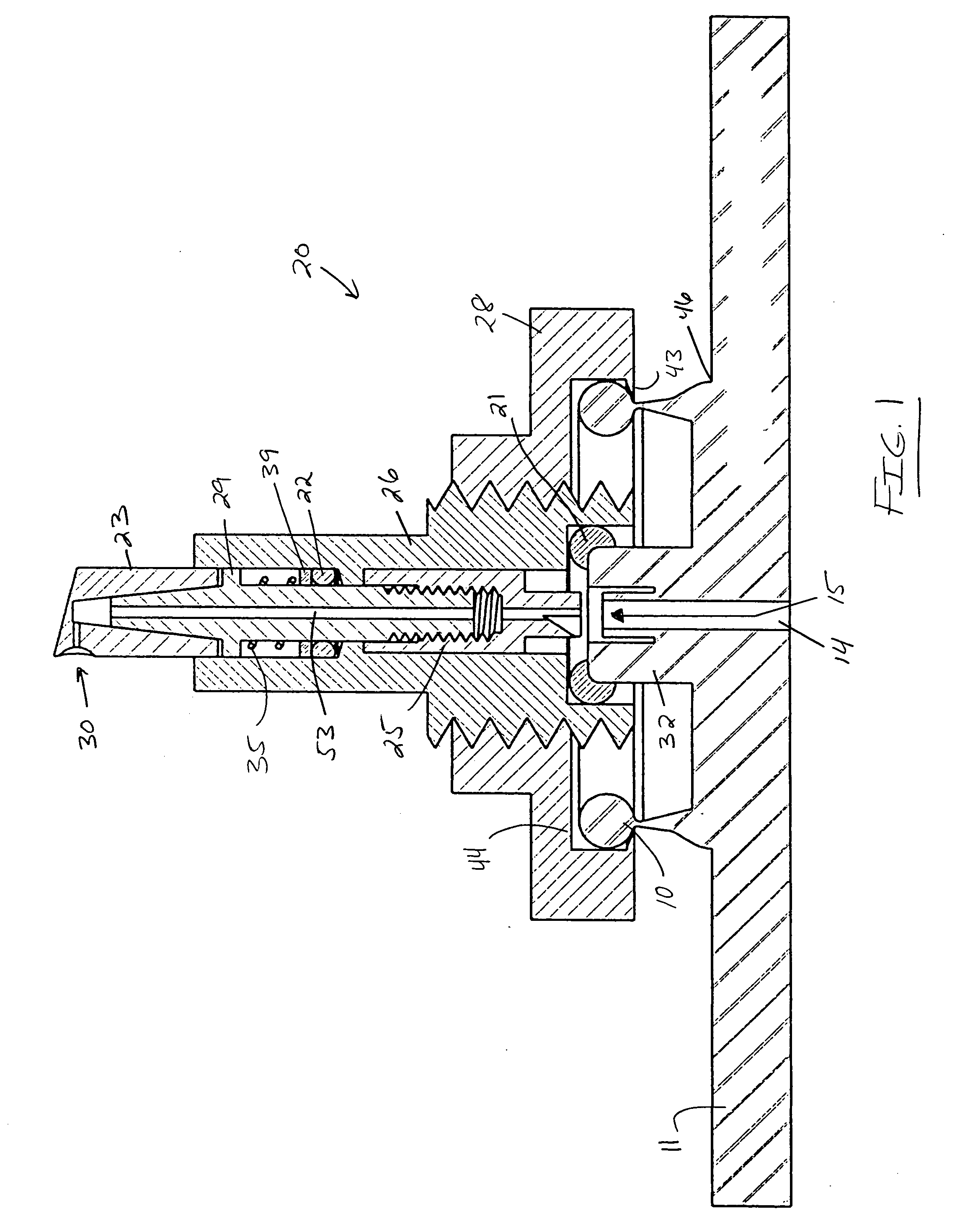

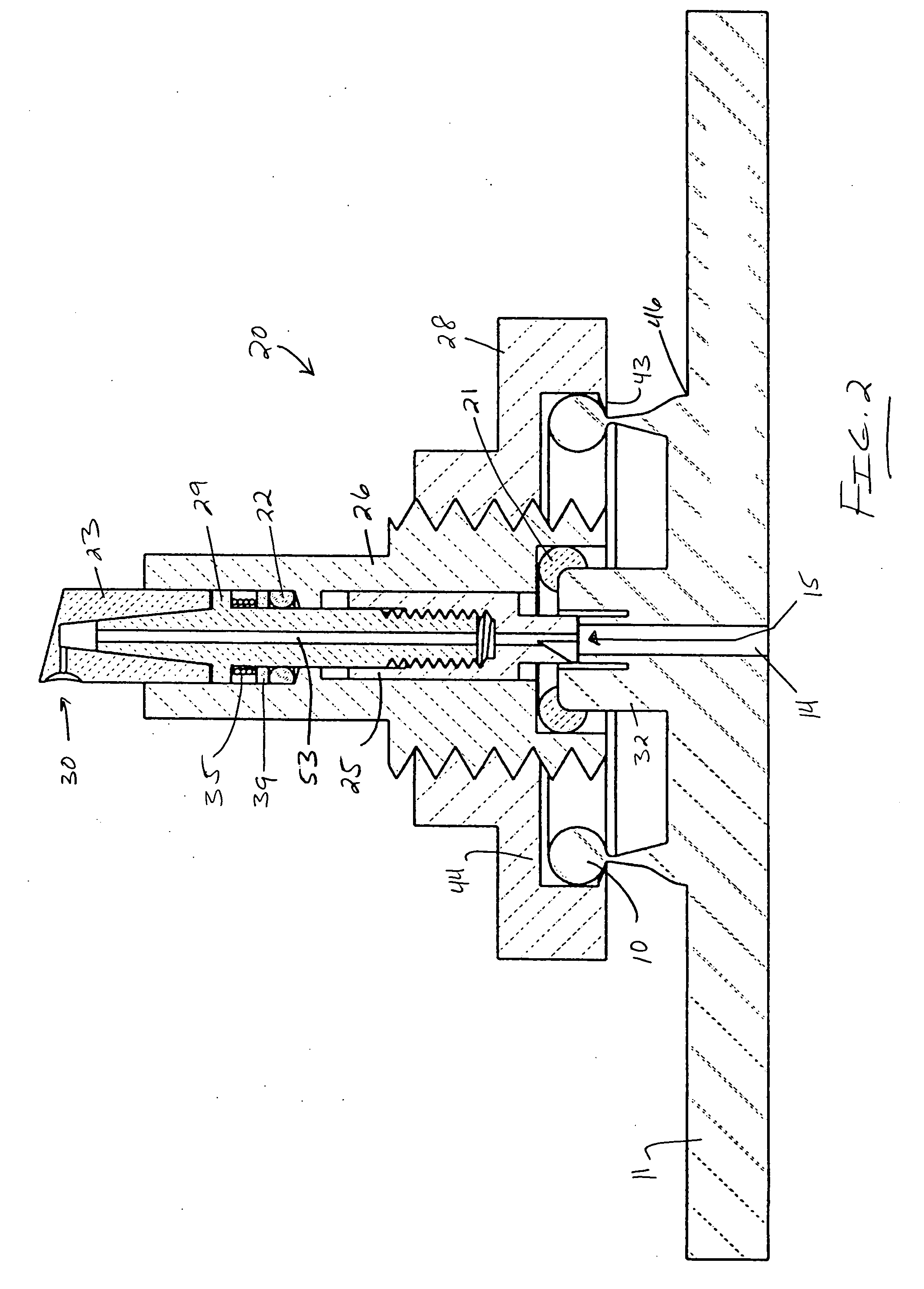

[0053]A typical aerosol can or container (as at 11) contains two substances. One substance is an inert gas used as a propellant 12. The second substance is a liquid product 13, such as a lubricant, to be delivered by way of the propellant 12. The inert gas or propellant 12 is at high pressure and essentially pushes on the product 13 such that the product 13 travels through the container conduit 14 and exits the container 11 via a container outlet 15 as generally depicted in FIG. 18 via a product flow path generally depicted by arrows 100.

[0054]The aerosol can or container 11 is valved such that the product 13 cannot escape the aerosol can or container 11 until the valve is opened, usually by pushing down on its nozzle. A container conduit 14 extends from the valve, which is at the top of the aerosol container 11, to the bottom of the aerosol container 11. If the valve is opened and the aerosol container 11 is upright, the product 13 is pushed by the pressurized inert gas 12 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com