Dishwasher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

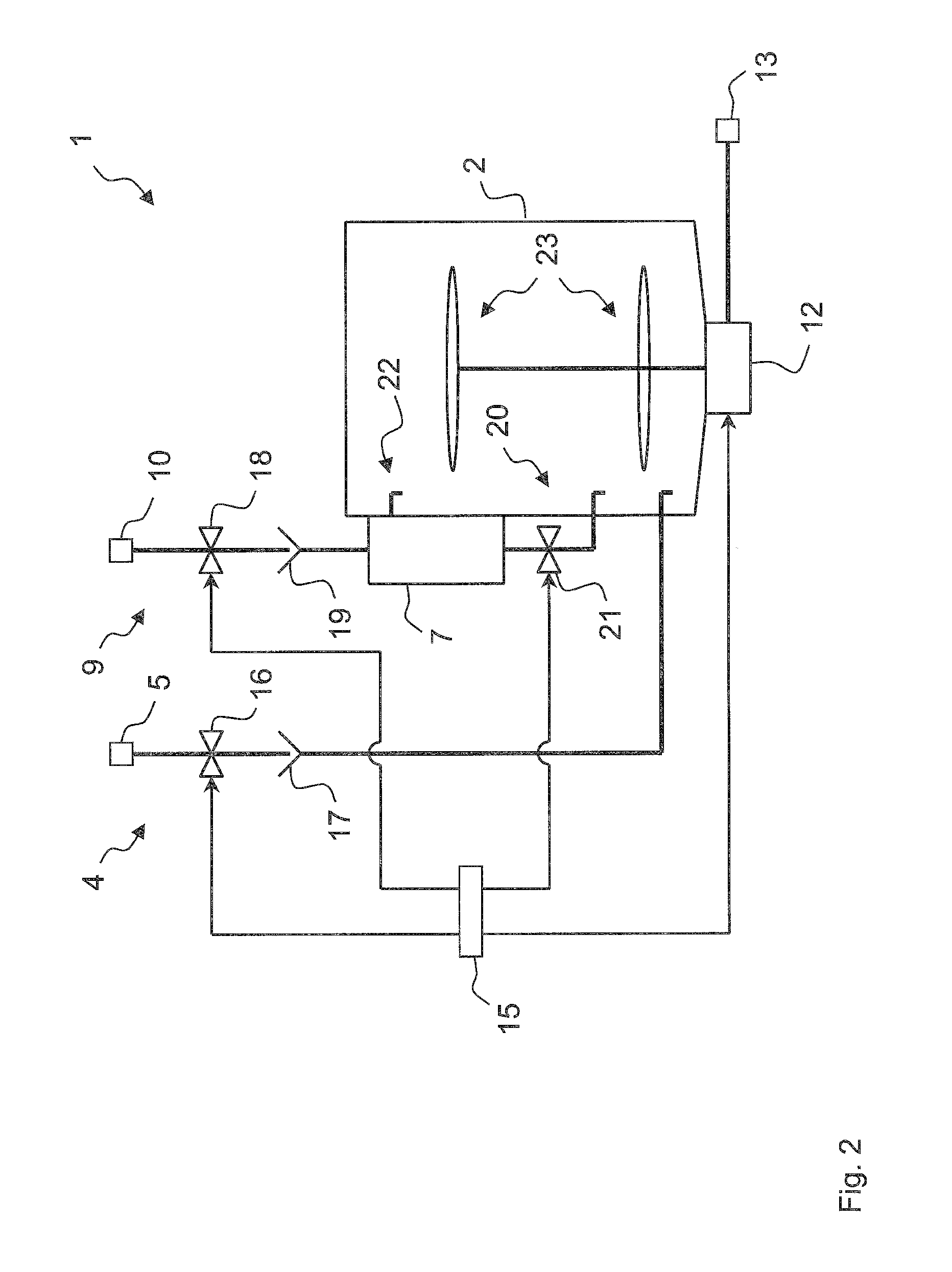

[0038]In the following figures, corresponding parts are given the same reference symbols. A reference symbol and explanation is given here only to those components of a dishwasher that are necessary for understanding the invention. Obviously the dishwasher according to the invention may contain other parts and components.

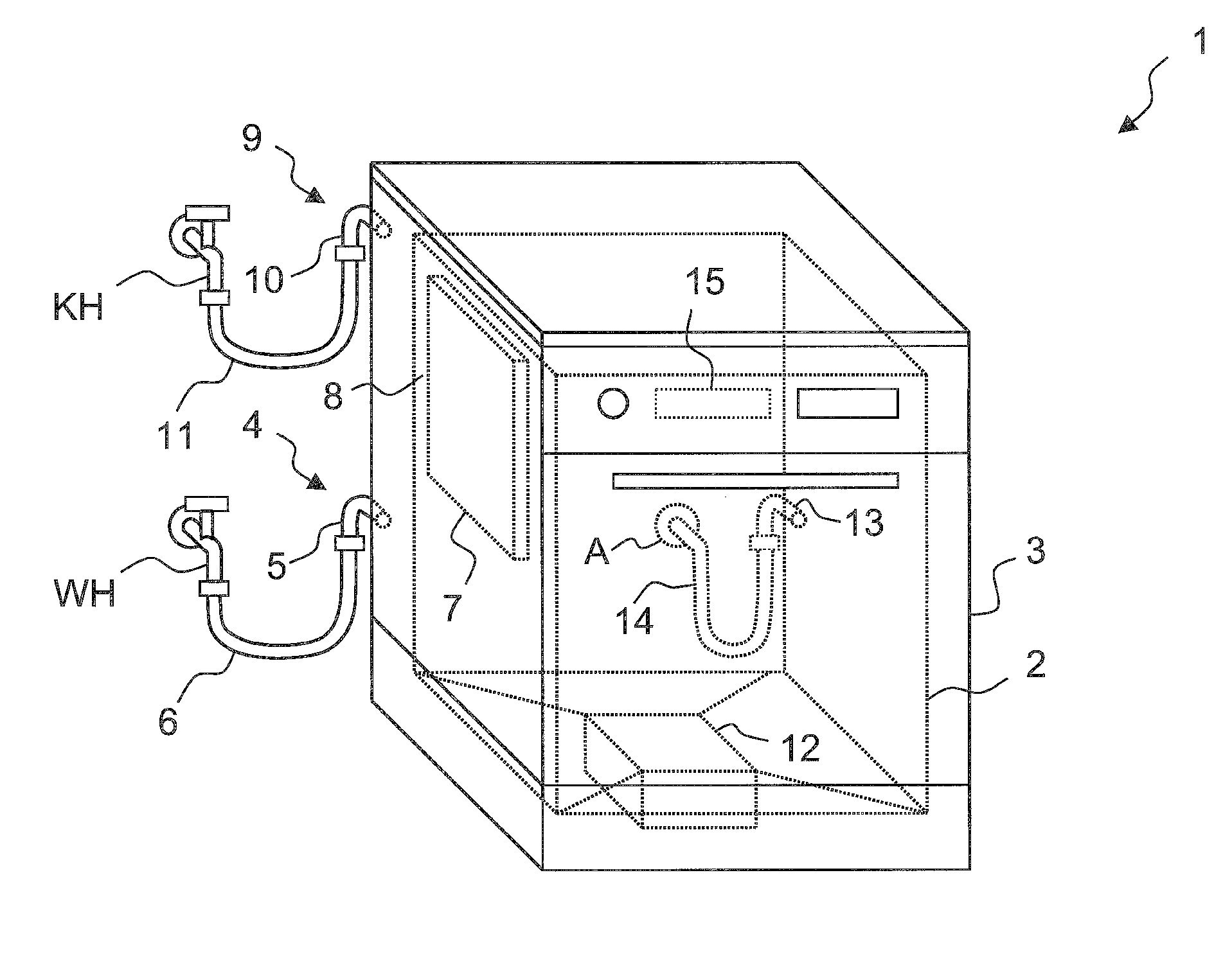

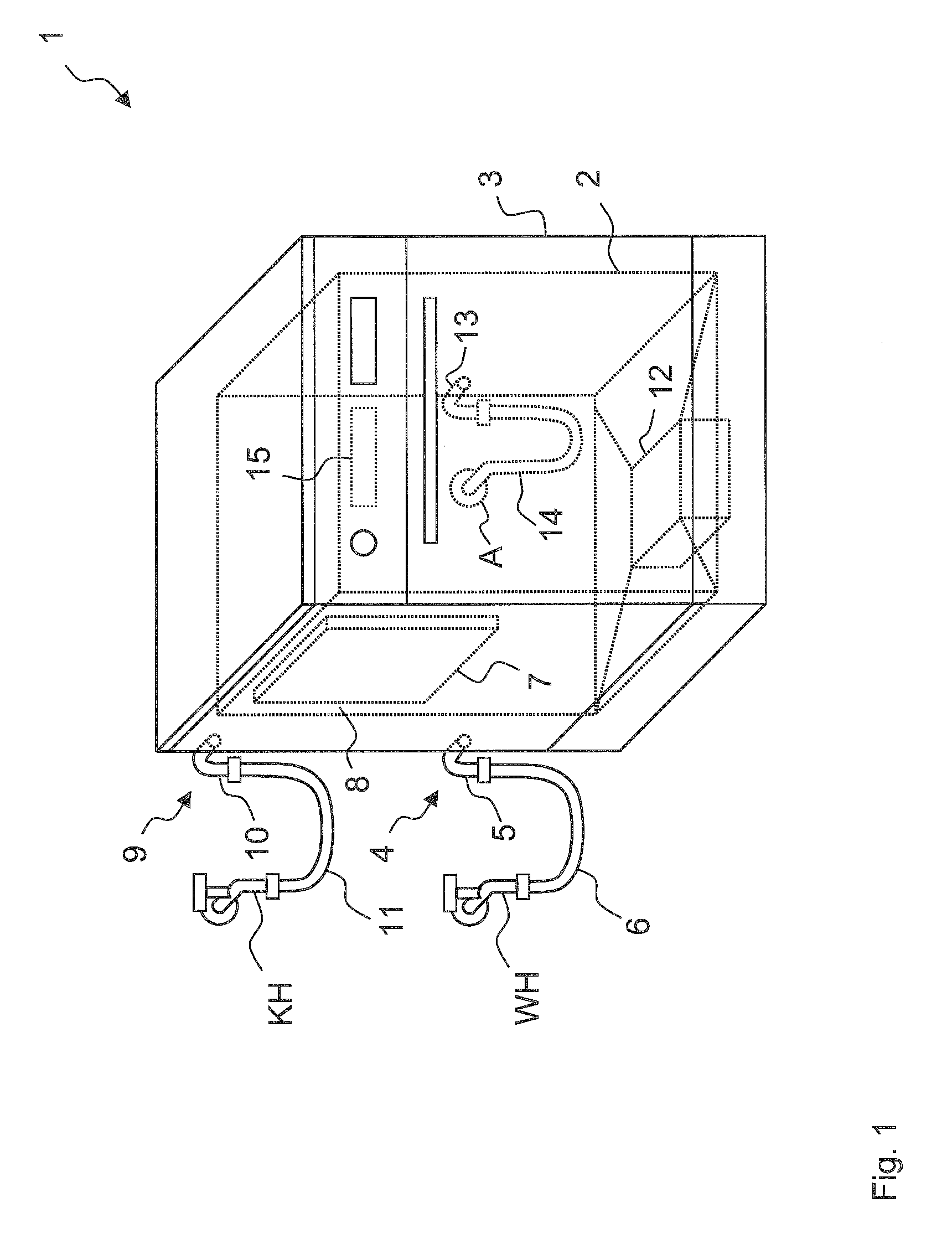

[0039]FIG. 1 shows a schematic 3-dimensional diagram of an advantageous exemplary embodiment of a dishwasher 1 according to the invention. This comprises a washing container 2, which can be closed by a door 3, to create a wash cabinet for washing dishes.

[0040]A hot-water intake fitting 4 (shown schematically) is arranged on the rear side of the dishwasher 1, as is common practice with dishwashers provided for the North American market. Said fitting comprises a hot water connector 5, to which a connecting hose 6 is connected. The connecting hose 6 is connected to an external hot water supply WH in the intended manner. The standard practice is to connect it, as shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com