Protective cover for smoking pipe and method

a protective cover and pipe technology, applied in the field of smoking accessories, can solve the problems of pipe formation from configurations that do not allow self-support of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

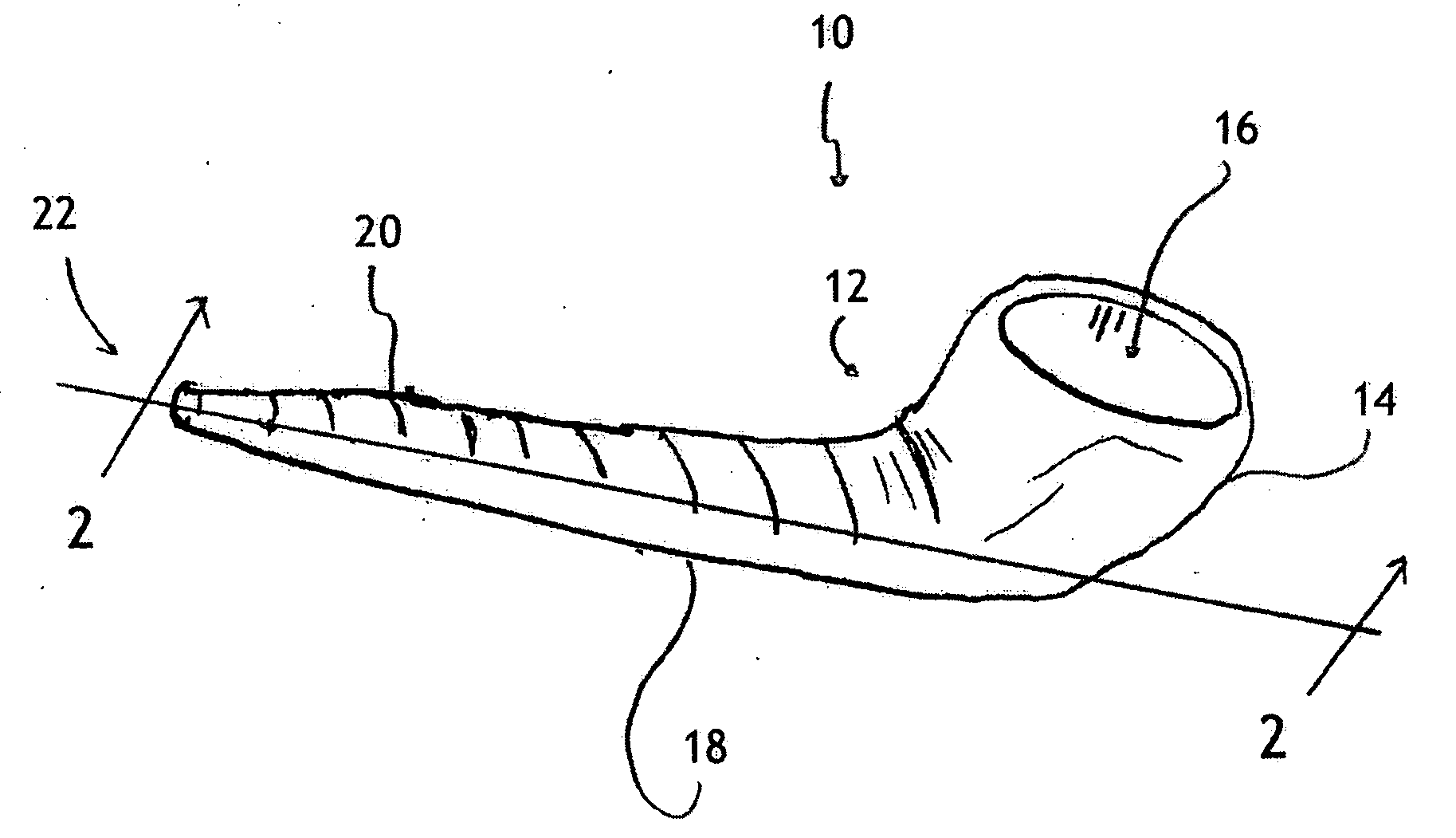

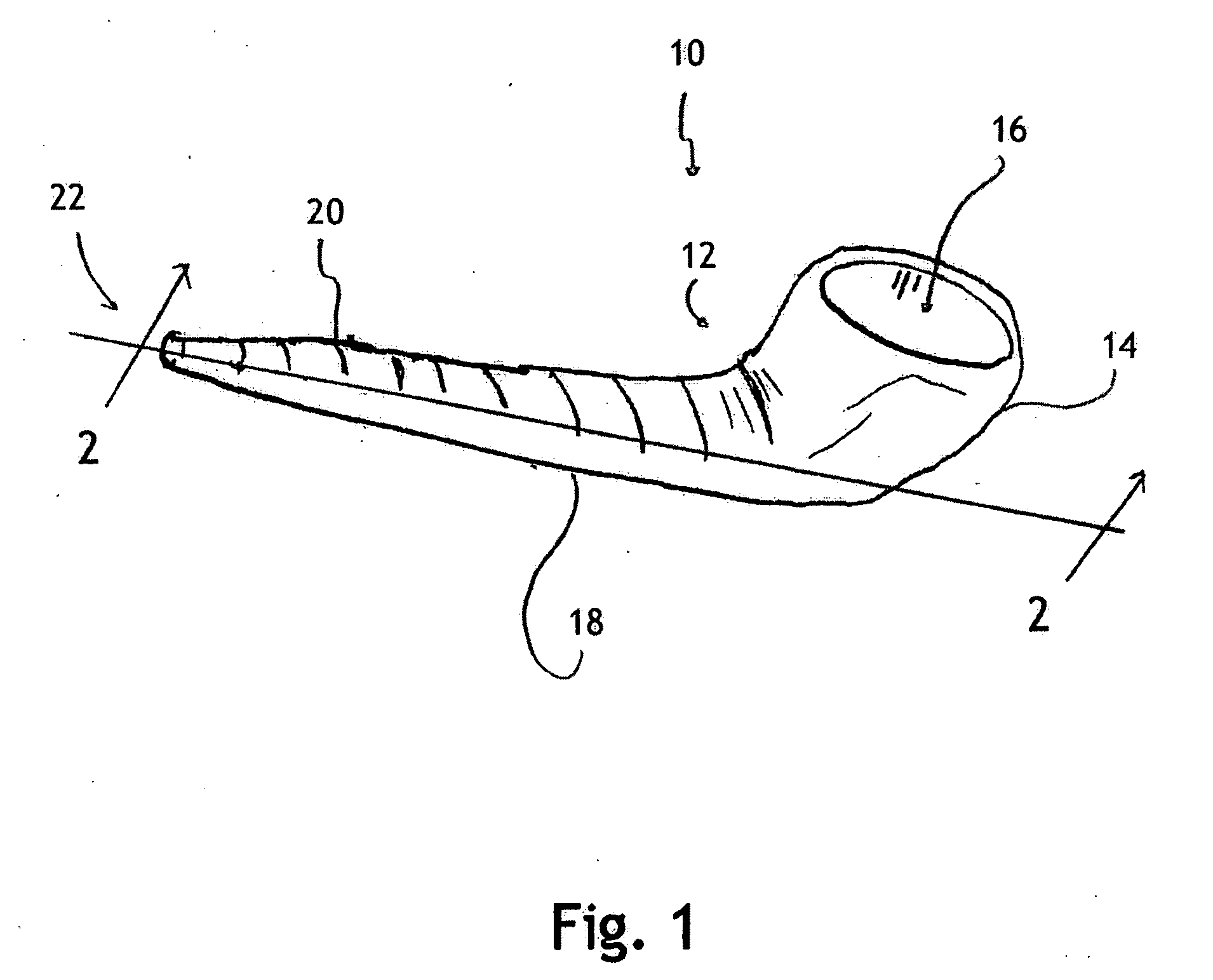

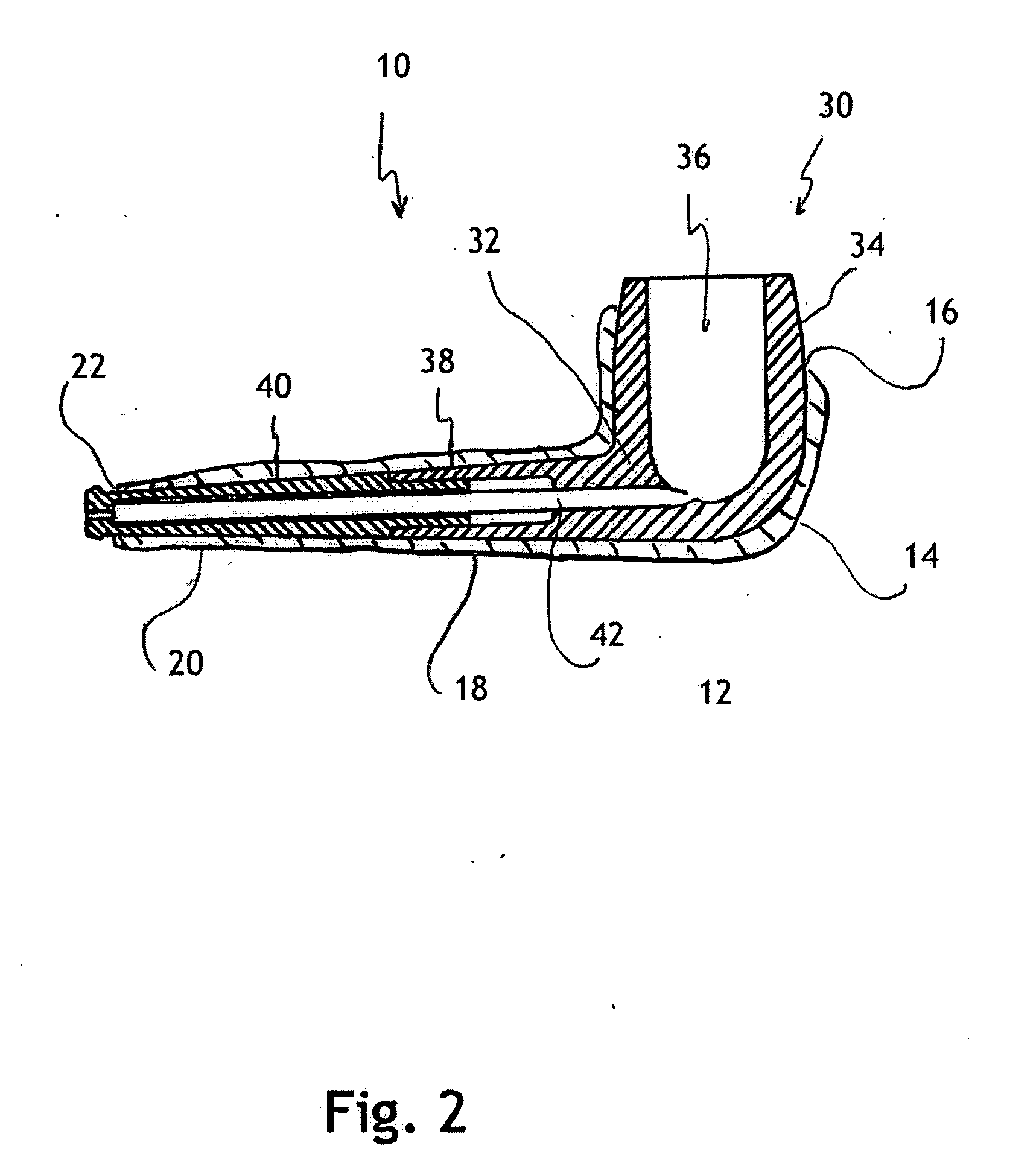

[0031]Turning now to the drawings and, more particularly to FIG. 1, a protective cover for a smoking pipe is illustrated generally at 10 and includes a generally elongate, generally tubular body member 12 which is formed from elastic material. The body portion 12 includes a bowl portion 14 formed at one end thereof, a stem portion 20 formed at an opposite end thereof and a shank portion 18 extending intermediate the bowl portion 14 and the stem portion 20. The bowl portion 14 is formed with an access opening 16 therein. The shank portion 18 and stem portion 20 extend linearly from a generally upstanding bowl portion 14 and terminate at a utility opening 22 in the stem portion 20. The body member 12 is configured in the general manner of a smoking pipe and is hollow.

[0032]The entire protective cover 10 is formed from a generally elastic resilient material. An object of invention is to provide a protective cover for the surface of a smoking pipe and the resilient material which may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com