Efficient punching-free laser cutting process and cutting equipment

A laser cutting and drilling-free technology, applied in laser welding equipment, welding/cutting auxiliary equipment, metal processing equipment, etc., can solve problems such as poor fixing effect, improve processing effect, improve use effect, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

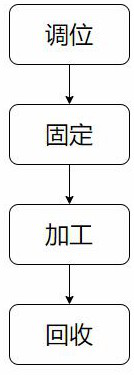

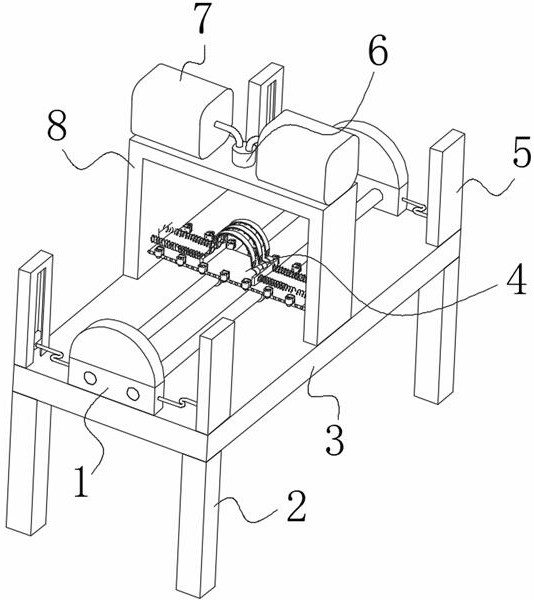

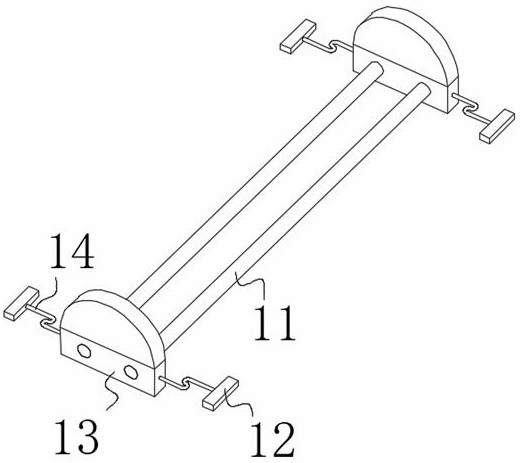

[0032] use Figure 1-Figure 7 A high-efficiency perforation-free laser cutting process and cutting equipment according to an embodiment of the present invention are described as follows.

[0033] Such as Figure 1-Figure 7 As shown, a kind of high-efficiency perforation-free laser cutting process and cutting equipment according to the present invention comprises the following steps:

[0034] S1: Position adjustment, by adjusting the height of the supporting part according to the volume of the workpiece;

[0035] S2: Fixing, fixing the workpiece through the fixing parts on the cutting machine;

[0036] S3: processing, through the processing parts on the cutting machine to perform specific processing on the workpiece;

[0037] S4: Recycling, recycling the machined parts after processing.

[0038] A high-efficiency drilling-free laser cutting equipment, comprising a mounting plate 3, the top of the mounting plate 3 is uniformly provided with a guide frame 5, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com