Oiler for producing low-smoke and halogen-free cables and production method for low-smoke and halogen-free cables

A production method and technology of an oil filter, which is applied in the manufacture of cables/conductors, electrical components, circuits, etc., can solve problems such as easy scratches, rough appearance of cables, and poor brightness of appearance of cables, so as to avoid scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

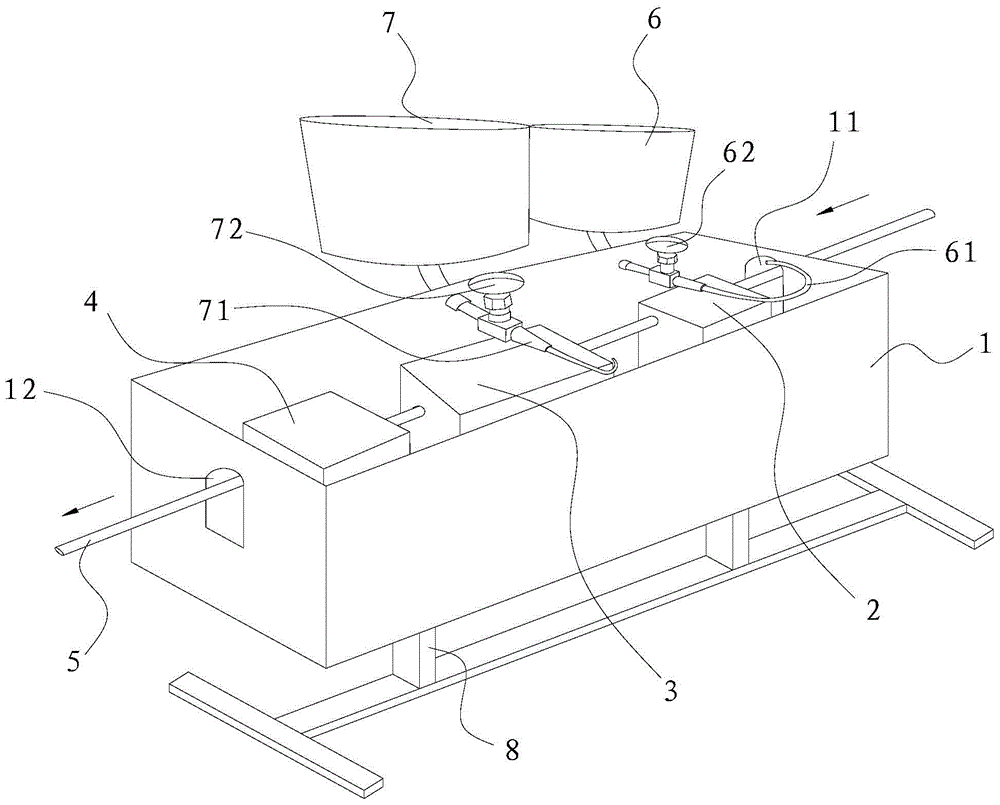

[0030] This preferred embodiment provides an oil filter for low-smoke, halogen-free cable production. like figure 1 As shown, the oil filter at least includes a hollow box 1 arranged on a bracket 8, and an oiling device 2, a water washing device 3 and a wiping device 4 are sequentially arranged in the box 1, and the box 1 is provided with an oiling device 6 and Water injection device 7. Wherein, the oiling device 2 , the water washing device 3 and the wiping device 4 are respectively provided with through holes for receiving the low-smoke halogen-free cables 5 to pass through.

[0031] The oiling device 2 is made of a sponge, and is used to coat the outer surface of the low-smoke, zero-halogen cable 5 with silicone oil; the washing device 3 is made of a sponge, and is used to wash off the outer surface of the low-smoke, zero-halogen cable 5 The excess silicone oil on the surface; the wiping device 4 is made of cotton cloth, and is used to remove excess silicone oil on the ou...

Embodiment 2

[0044] This preferred embodiment provides an oil filter for low-smoke, halogen-free cable production, the structure of which is basically the same as that of the preferred embodiment 1. The oiler at least includes a hollow box, and the box is provided with an oiling device and a wiping device in turn, and the oiling device and the wiping device are respectively provided with through holes for accommodating low-smoke halogen-free cables; wherein, the oiling device The device is used to coat the outer surface of the low-smoke zero-halogen cable with silicone oil; the wiping device is used to remove excess silicone oil on the outer surface of the low-smoke zero-halogen cable.

[0045] The difference is that as long as the amount of silicone oil in the oiling device can be strictly controlled, the thickness of the silicone oil coated on the surface of the low-smoke and halogen-free cable will be ideal after passing through the wiping device, and the low-smoke and zero-halogen cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com