Method and Apparatus for Cementing a Liner in a Borehole Using a Tubular Member Having an Obstruction

a tubular member and cementing technology, which is applied in the direction of drilling casings, borehole/well accessories, pipes, etc., can solve the problems of inability to use the wiper dart of the drill pipe member, the procedure just discussed is not suitable for use with the tubular member, and the inability to cement the liner in the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

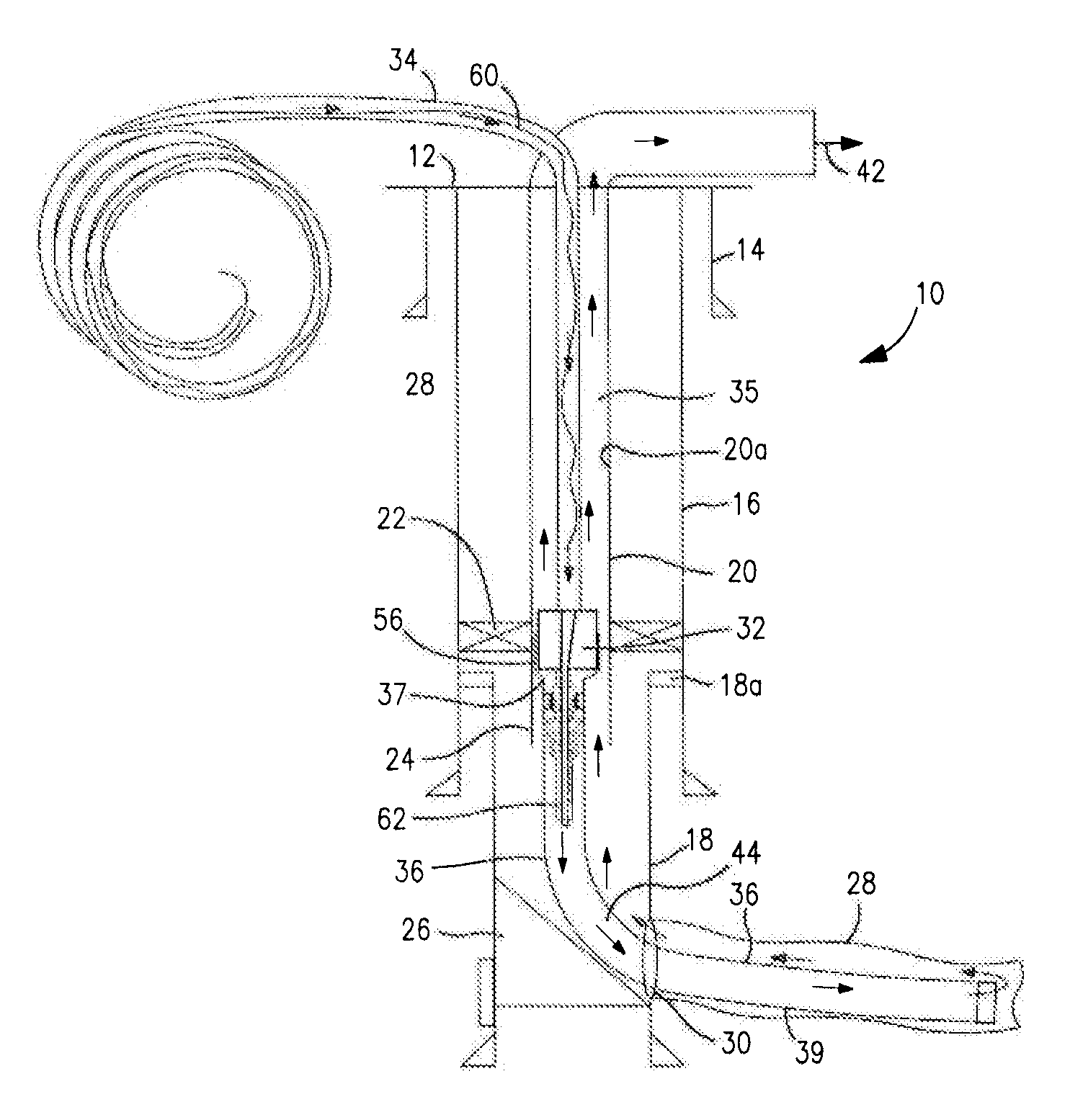

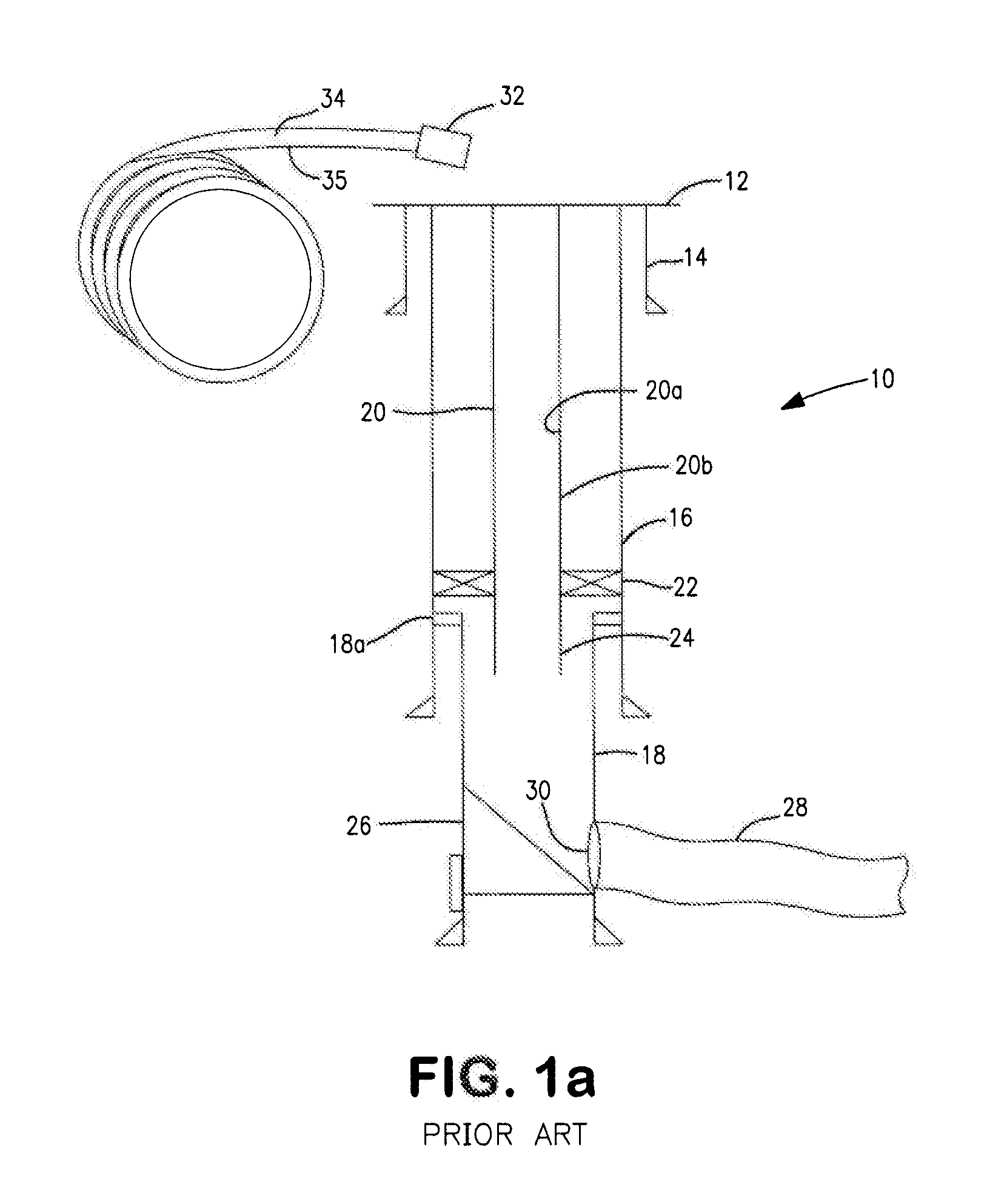

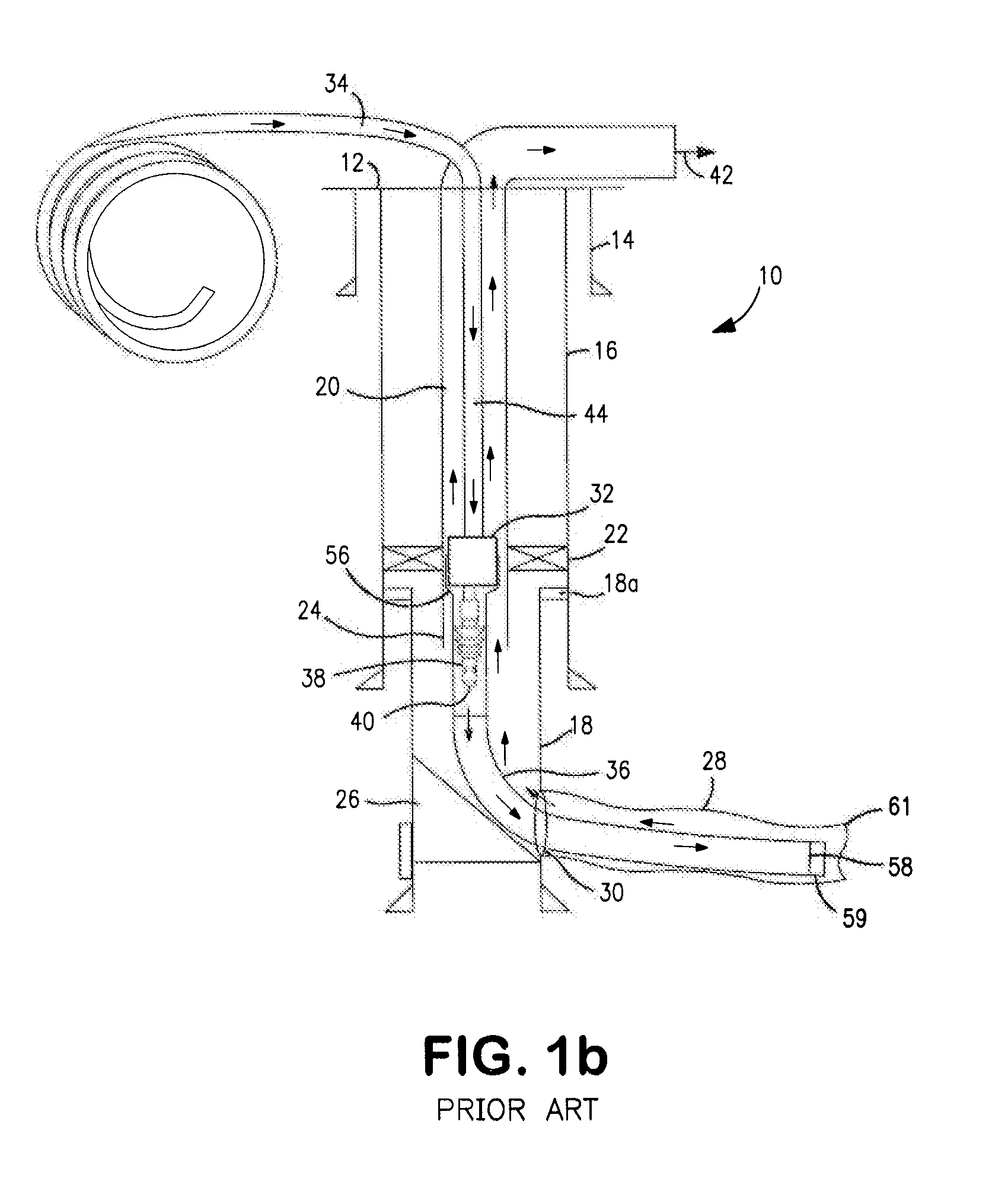

[0067]In the discussion of the Figures which follows, the same numbers will be used throughout to refer to the same or similar components. Various components are shown schematically which are otherwise considered to be well known to those skilled in the art for simplicity.

[0068]The method and apparatus of the present invention are useful with coiled tubing or other tubular members used for cementing liners in position in boreholes, such as drillpipe. For illustration, the method and apparatus are shown and discussed by reference to a coiled tubing system working through production tubing. The use of the method and apparatus is essentially the same with or without the production tubing.

[0069]In FIGS. 1a-1e a prior art method for cementing a liner in a borehole is shown. The first step, shown as FIG. 1a, is the completion of a cased wellbore 10 which extends from an earth surface 12 to a subterranean formation and includes an outer casing 14, a second casing 16 and a third casing 18 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com