Lightweight, low cost solar energy collector

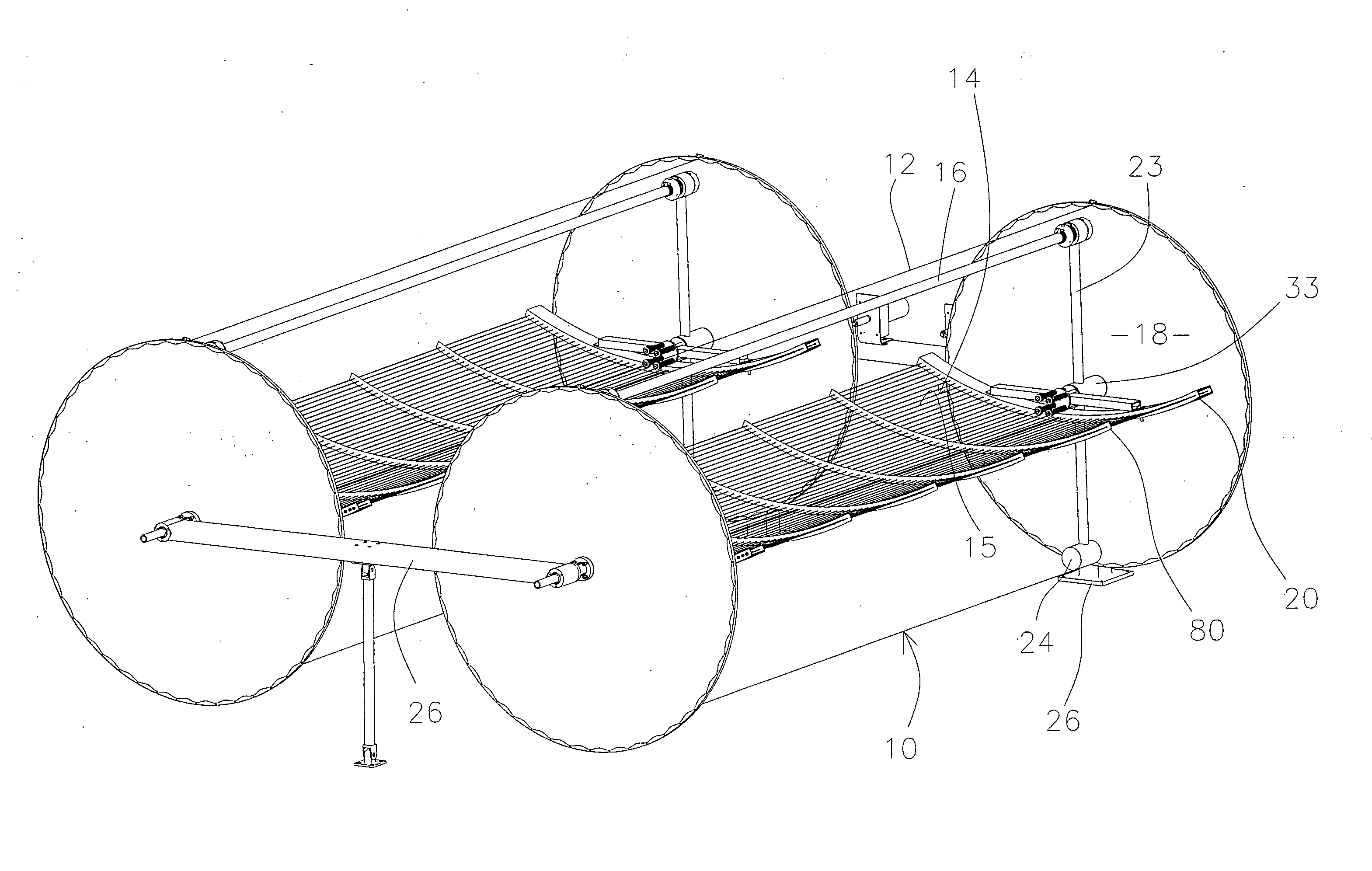

a solar energy collector, low cost technology, applied in the direction of solar heat systems, heat collector mounting/support, light and heating apparatus, etc., can solve the problems of not using additional costly structure, neither such patent discloses a transparent tubular enclosure, etc., to achieve the effect of reducing the sag or deformation of the array of fibers, reducing the cost of installation, and increasing the stiffness of the enclosure tub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

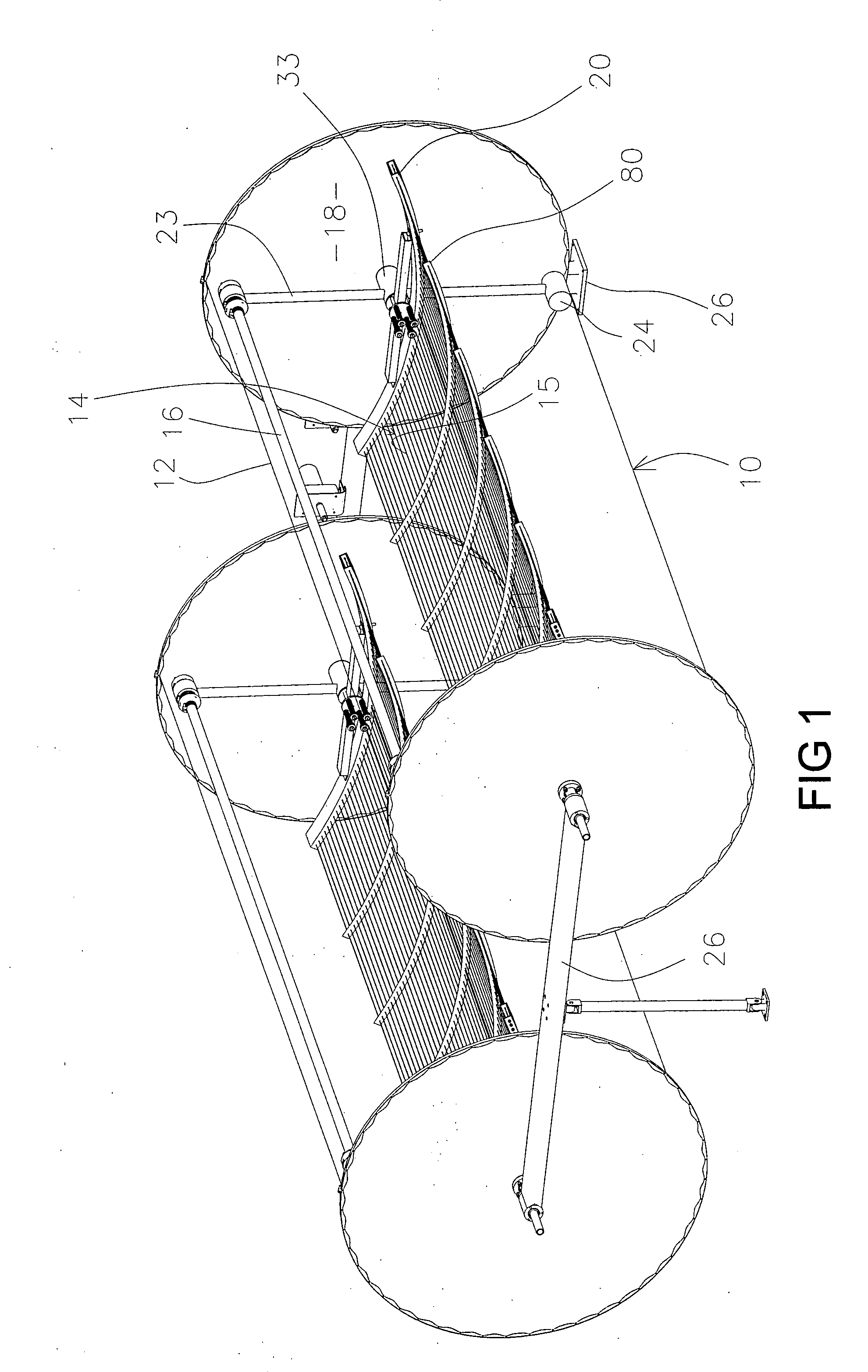

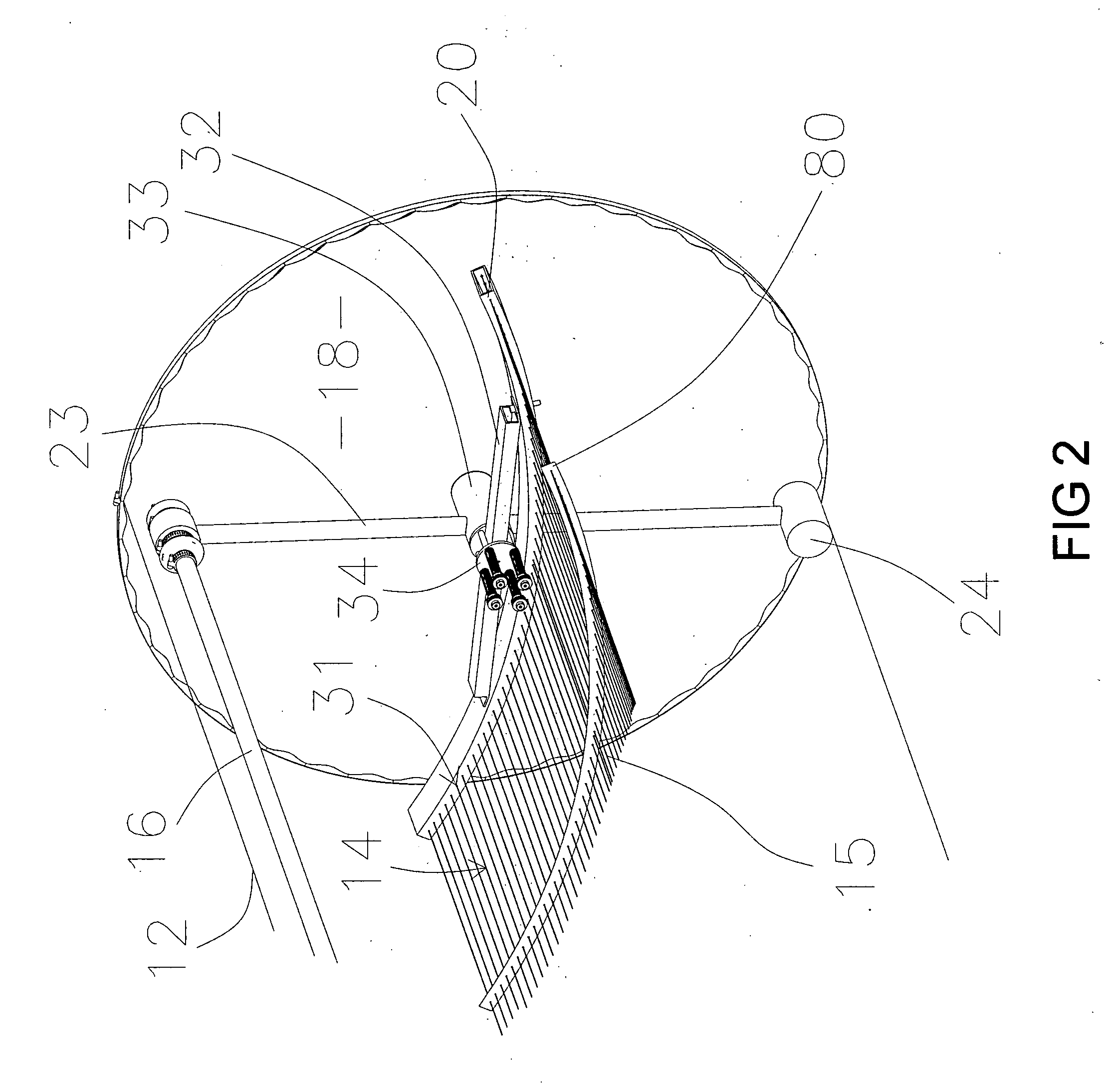

[0041]FIGS. 3 and 4 illustrate two embodiments used to secure anchorplate 20 to the hub 33. The first embodiment, shown in FIG. 3 utilizes springs to enhance axial compliance between the reflector assembly and transparent enclosure tube assembly. As shown therein, four symmetrically located shoulder bolts 28 extend through a pair of spaced anchorplate hubs 34 which are welded to the anchorplate crossbar 32. Each shoulder bolt 28 supports a corresponding helical spring 25 between hub 34 and a retainer 30. This arrangement precisely positions the anchorplate 20 relative to the hub 33 in all directions and rotations except along the hub axis. In the direction of the hub axis, the compliance of the helical springs 25 allow the anchorplate 20 to attain an optimal position relative to the hub 33 for maintaining string tension under a variety of the pressure and thermal loadings.

second embodiment

[0042]The second embodiment, shown in FIG. 4 depends upon an endplate 18 and or strings 15 and or enclosure tube 12 to provide axial compliance between the reflector assembly and tube assembly. As shown therein, the anchorplate 20 is attached to the hub 33 via a pinned and bolted joint. The pins 27 precisely position the anchorplate 20 relative to the hub 33 in all directions and rotations. The bolts 29 transfer loads from the anchorplate 20 to the hub 33.

[0043]FIGS. 5 and 6 illustrate the manner in which the hub 33 is attached and sealed from air leakage to the endplate 18. FIG. 5 provides a cross section view of the hub 33 to endcap 18 interface. As shown therein, the hub 33, is reduced in diameter to provide a shoulder 41 for axial positioning and sealing against the endcap 18. A gasket 39 is provided to ensure the seal and provide a soft interface with the endcap 18. A bolt ring 20 and gasket 42 are located on the outside of the collector enclosure. Bolts 43 secure the bolt ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com