Foamable alcoholic composition

a foaming composition and alcoholic composition technology, applied in the direction of drug compositions, aerosol delivery, detergent compounding agents, etc., can solve the problems of aerosol products generally more expensive to manufacture than non-aerosol foams, and the foam products based on alcoholic compositions are problematic. to achieve the effect of reducing dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

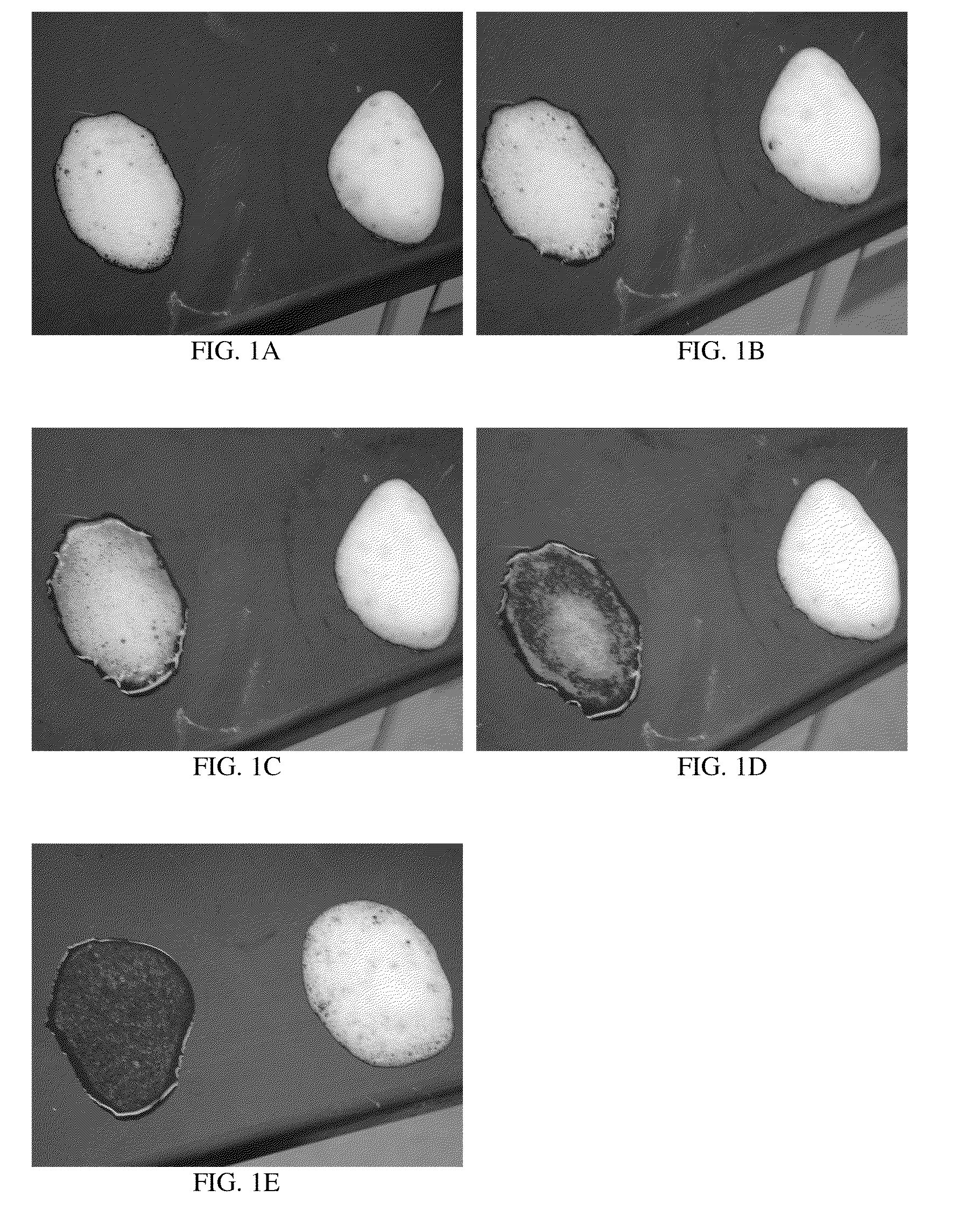

Image

Examples

examples

[0065]Example 1 was prepared by dispersing the fluorosurfactant, DEA-C8-18 perfluoroalkylether phosphate, in ethanol with slow to moderate agitation until a homogeneous dispersion was achieved. Next, humectant was added and mixed until the mixture was homogeneous. Water was added, with mixing. The solution was agitated until a homogeneous mixture was achieved.

[0066]The foamable mixture was passed through an Airspray® foaming pump. The foam was rated for quality and stability as described hereinbelow, and the results are summarized in Table 2.

[0067]A simple 1-5 rating system was used to rate the foam of each system, with 5 being the best.

[0068]Foam Quality Rating Scale: Quality is a measurement of the visible appearance of the dispensed foam when dispensed from a typical commercial foaming pump.

[0069]Scale 0-5

[0070]0 No foam

[0071]1 Watery, weak foam with large loose bubbles

[0072]2 Large, loose bubbles, some small bubbles

[0073]3 Foam has about equal amounts of smaller and larger bubbl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| foamable | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com