Organometallic-compound feeder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

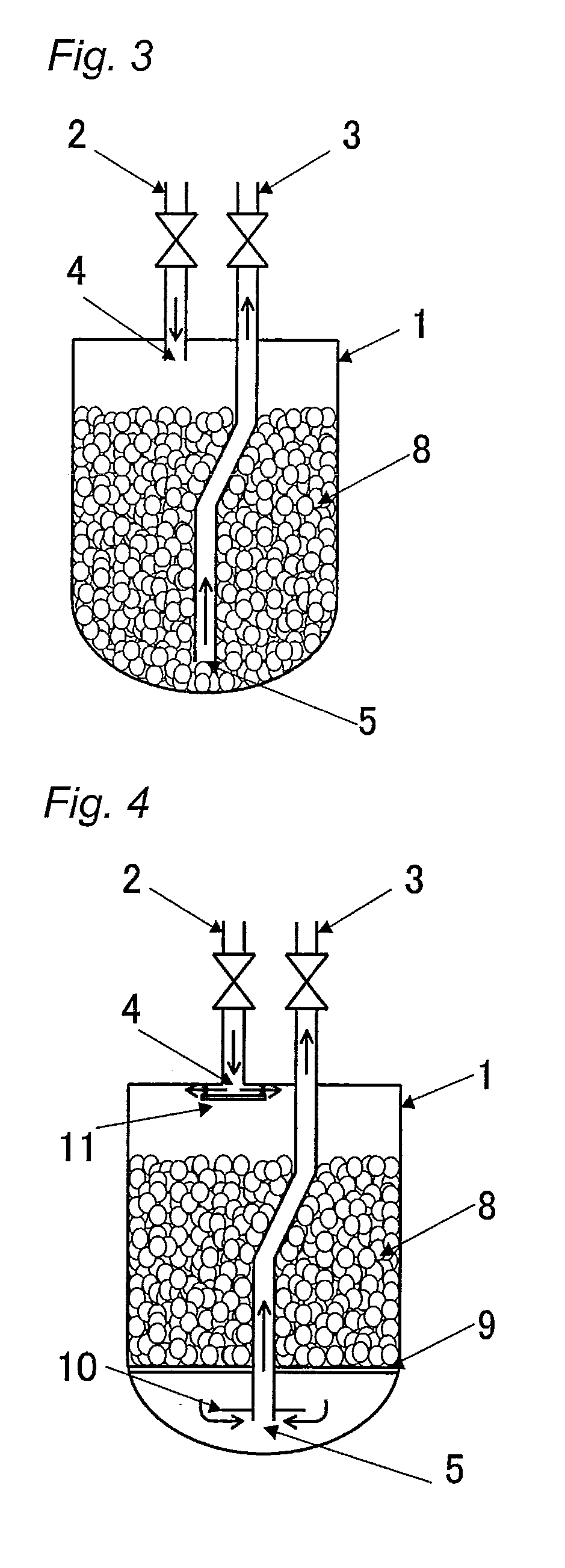

[0090]An organometallic compound feeder of the present invention was constructed which was similar to that shown in FIG. 4 except that a baffle plate was attached to a tip portion of a discharging tube, that is, a level of an outlet. A bottom portion of a packing container 1 was curved and the packing container 1 had a volume of about 1300 cm3 (an inner diameter: 108 mm, a height: 147 mm). A support plate 9 (a size of opening: 2 mm metal mesh) was placed at 26 mm from a bottommost position of the packing container. A distribution plate 11 (a disc-shaped flat plate: a diameter of 18 mm) was attached at the carrier gas inlet 4 in parallel to a top plate of the packing container 1 so that a distance between the top plate of the packing container and the distribution plate 11 was 3 mm, whereby the carrier gas was introduced in a direction almost vertical relative to the central axis of the container. Further, a carrier gas discharging tube 3 (an outer diameter 8 mm, an inner diameter 6 ...

example 2

[0095]The alumina spheres were allowed to carry TMI thereon in the same packing container 1 as that used in Example 1, in the same manner as that in Example 1 except that the diameter of the baffle plate 10 (the disc-shaped flat plate) which was attached to the tip portion of the carrier gas discharging tube 3 (the carrier gas outlet 5) was 50 mm.

[0096]The usage rate of TMI was determined in the same manner as that in Example 1. The results are shown in FIG. 8. The TMI concentration was kept stable until the usage rate reached about 87%, and then reduced.

example 3

[0097]The alumina spheres were allowed to carry TMI thereon in the same packing container 1 as that used in Example 1, in the same manner as that in Example 1 except that the diameter of the baffle plate 10 (the disc-shaped flat plate) which was attached to the tip portion of the carrier gas discharging tube 3 (the carrier gas outlet 5) was 80 mm.

[0098]The usage rate of TMI was determined in the same manner as that in Example 1. The results are shown in FIG. 9. The TMI concentration was kept stable until the usage ratio reached about 85%, and then reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com