Packaged Food Product

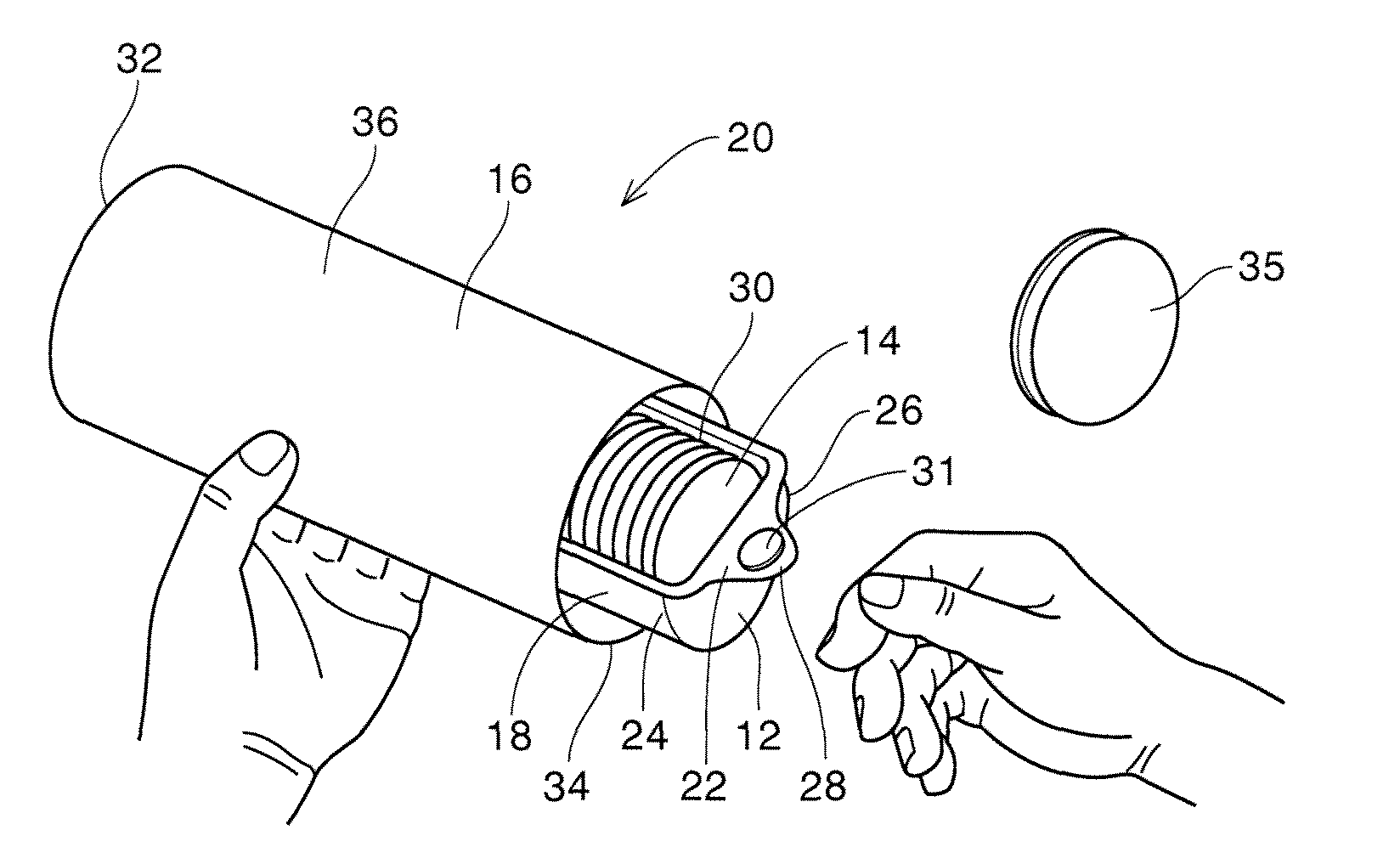

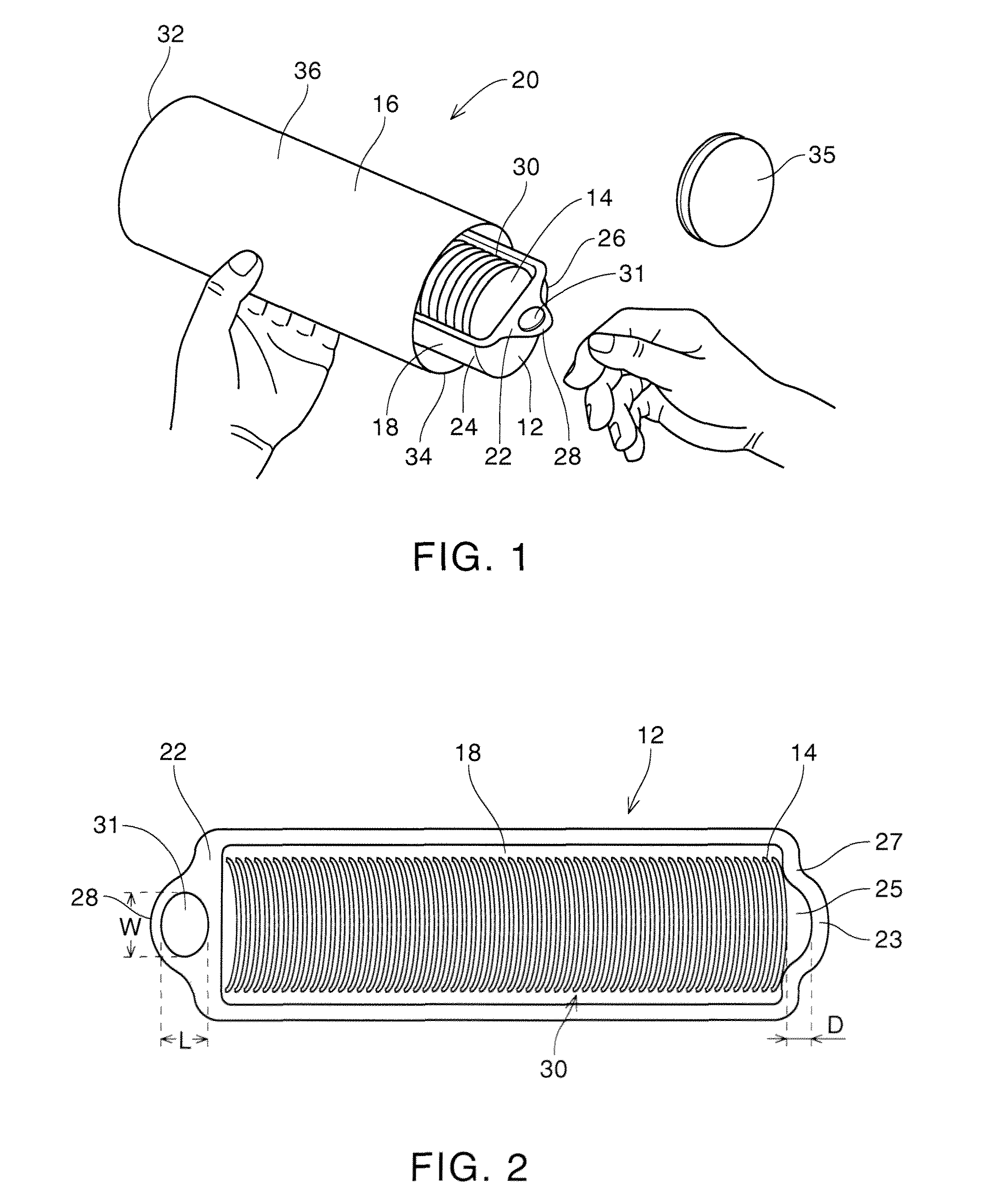

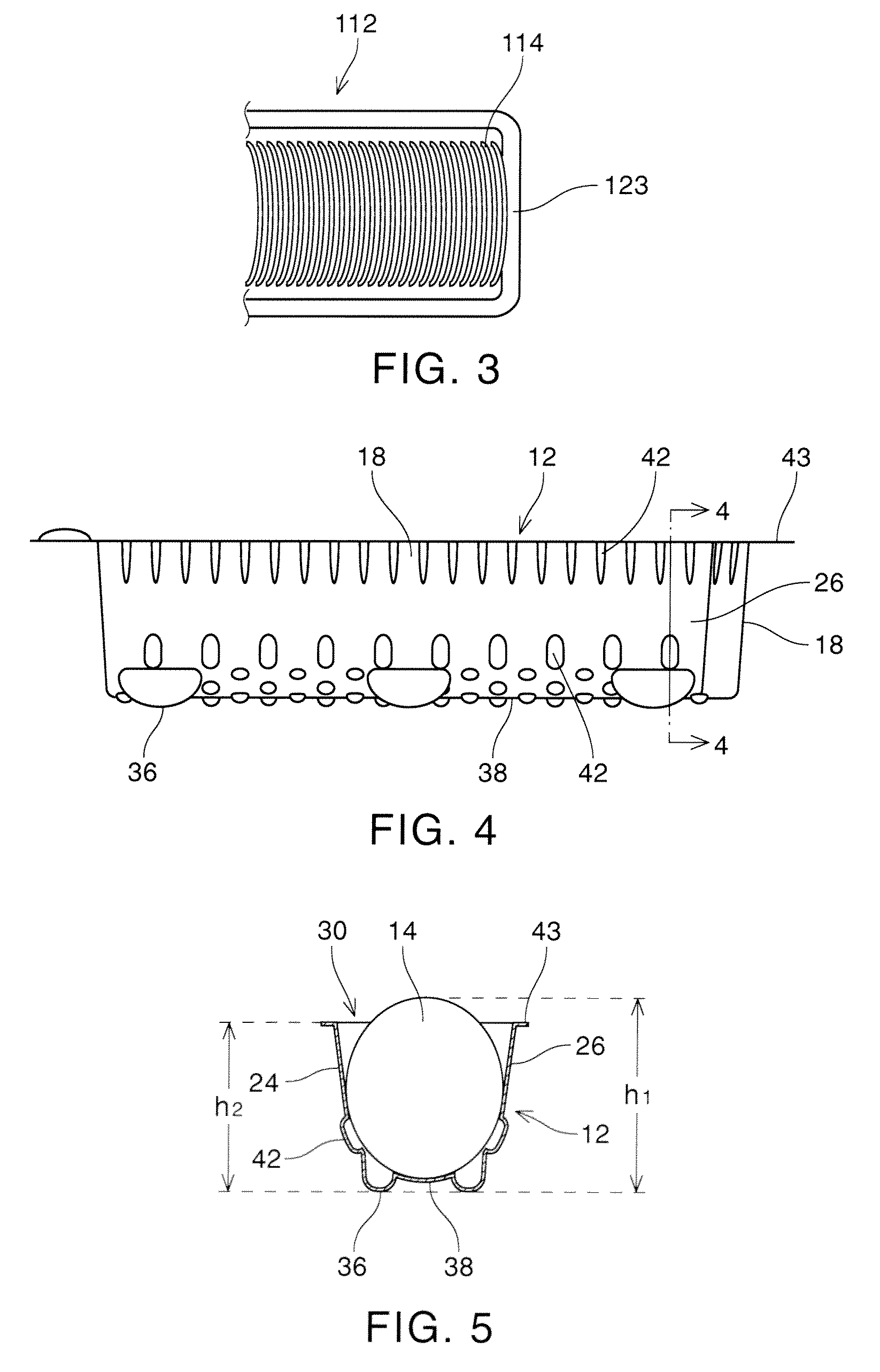

a food product and packaging technology, applied in the field of packaging food products, can solve the problems of requiring space for transportation and display, chip snacks in tubular containers may crack or break during shipping, and sometimes fragile chips, so as to reduce the transmission of force and reduce the effect of breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0049]A tray was manufactured by extruding a biodegradable corn starch material. The tray has a thickness of 0.55 mm. 100% whole molded potato chips (brand name; Pringles® Original Mix, manufactured by The Procter & Gamble Company) were manually stacked into the trays (74 chips per tray) and the potato chips on the trays were put in each tubular container (container size: diameter 65 mm, and height 210 mm). 12 (Twelve) tubular containers were packed into a cardboard case (3 (columns)×4 (lines) cases) as seen in FIG. 5. The cardboard case was subjected to a drop test. There were seven (7) free drops of the cardboard case during the dropping test, following the instruction shown in Table 1 and FIG. 6. In FIG. 6, the numbers from 1 to 6 shows each plane of the cardboard case. After the dropping test, the molded potato chips were retrieved from the tubular container. The molded potato chips were carefully sorted by (i) whole chips (>90% weight), (ii) broken chips (>50%, <90% we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com