Radial jet air impingement nozzle, oven and method

a technology of air impingement nozzle and radial jet, which is applied in the direction of baking, household heating details, containers, etc., can solve the problems of overcooked and undercooked areas of food products, and achieve the effects of high heat distribution cooking, enhanced heat transfer to the product, and more homogeneous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]It is contemplated that the jet nozzles of the present disclosure can be used in any type of oven that uses impingement air. By way of example and completeness of description, the nozzles are described herein for use with a countertop oven.

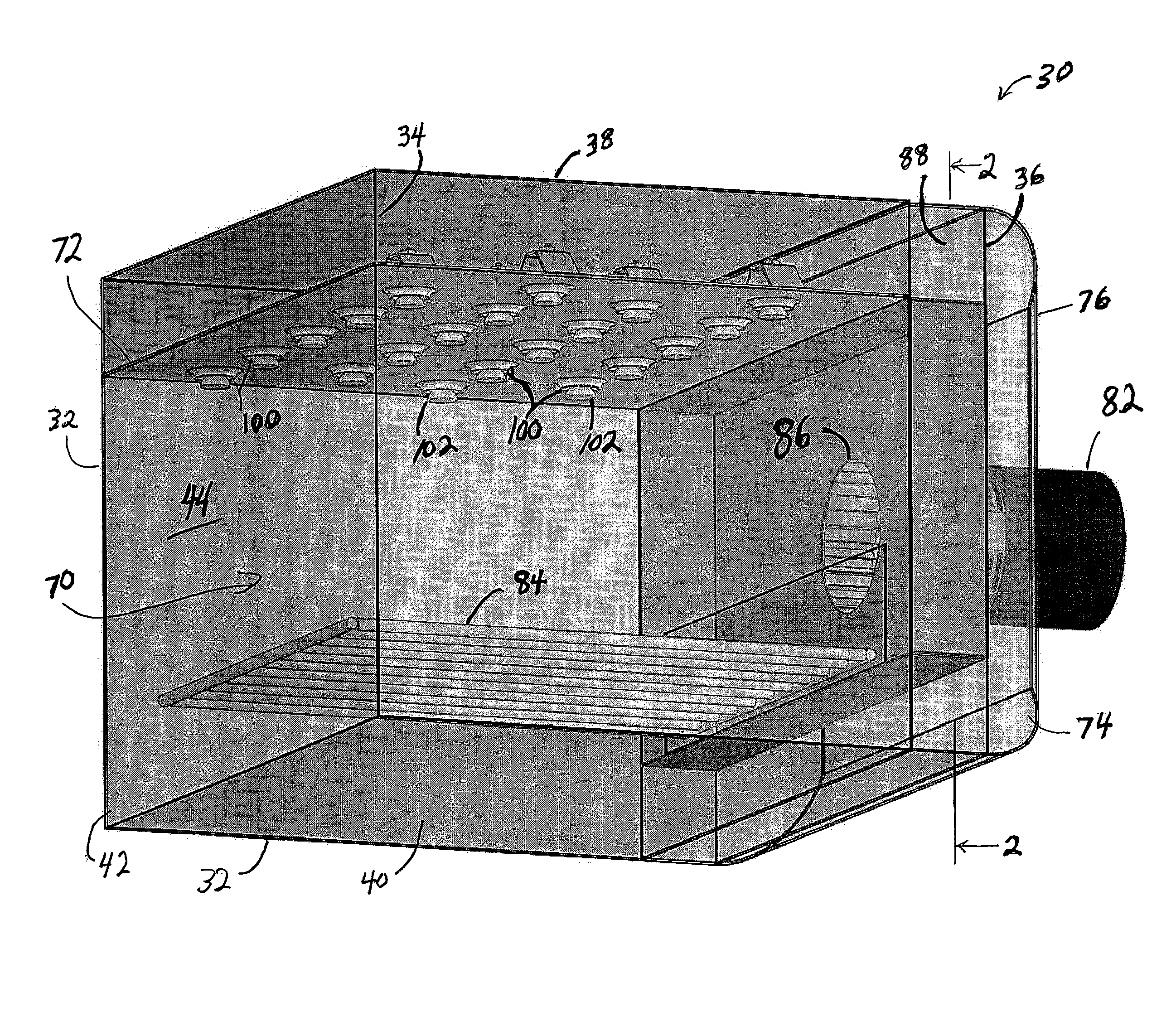

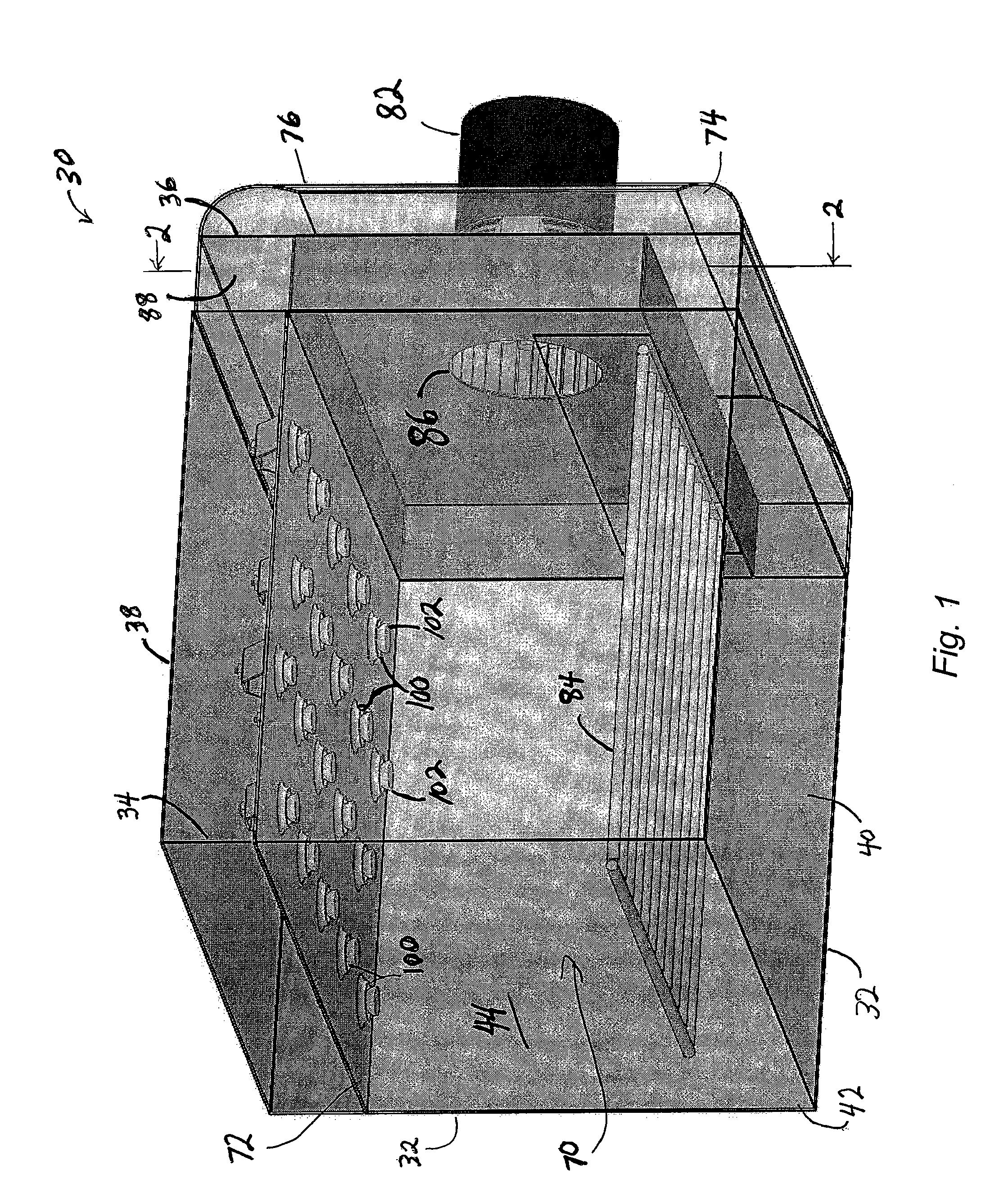

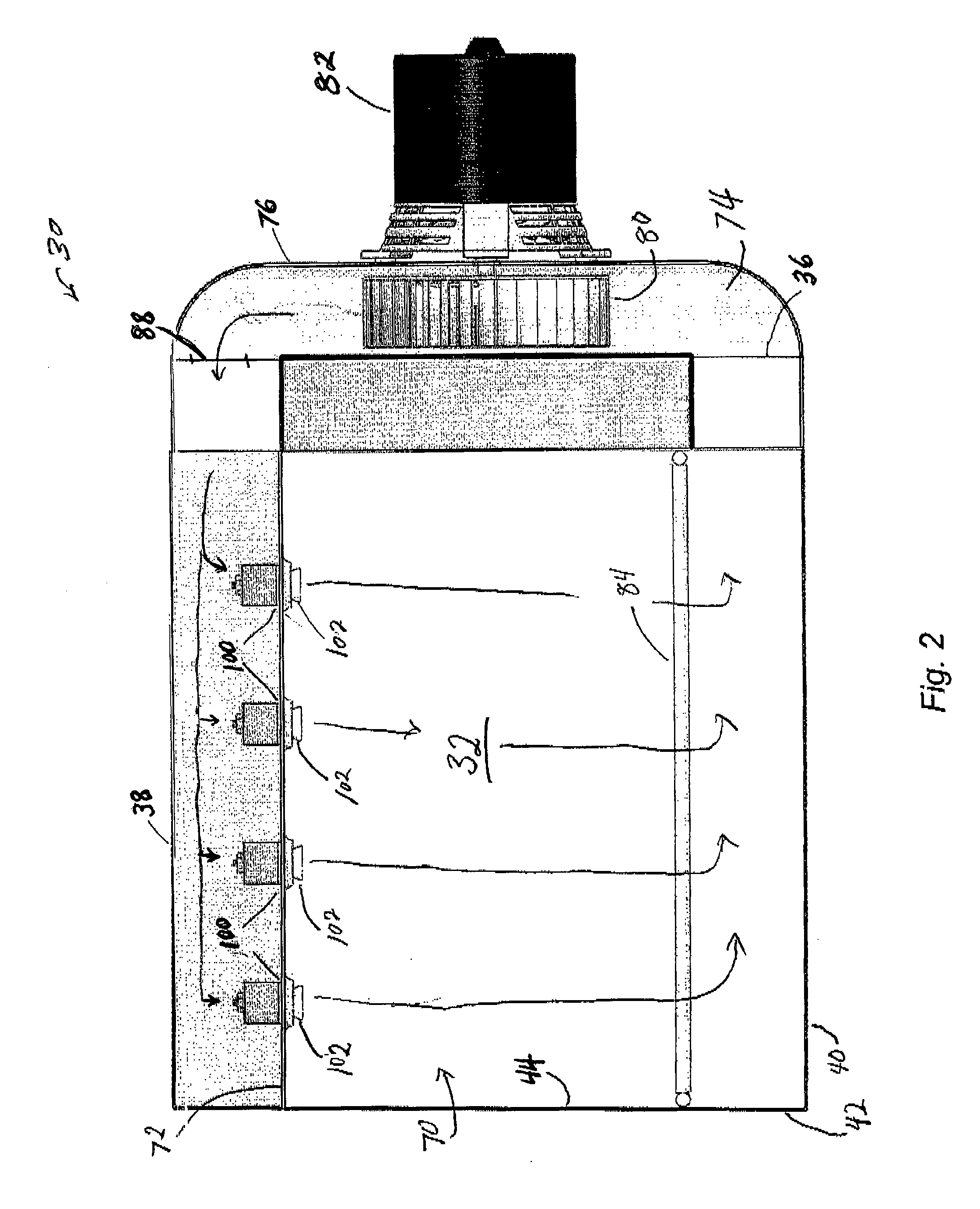

[0047]Referring to FIGS. 1 and 2, an oven 30 of the present disclosure comprises a pair of side walls 32 and 34, a back wall 36, a top wall 38, a bottom wall 40 and a front wall 42. Front wall 42 comprises a door 44 and a control panel 50 (shown in FIG. 3), which, for example, may be located above, below or beside door 44. A handle (not shown) is disposed on door 42 for opening the door in a pull down manner or a side rotatable manner.

[0048]Oven 30 comprises an oven chamber 70 defined by side walls 32 and 34, back wall 36, bottom wall 40 and a jet plate 72. Jet plate 72 is disposed below top wall 38. Oven 30 further comprises a fan box 74 defined by side walls 32 and 34, back wall 36, top wall 38 and a wall 76. A fan 80 is disposed in fan bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com