Burner with flame ring stabilization chamber

a technology of flame ring and stabilization chamber, which is applied in the direction of gaseous heating fuel, combustion types, domestic stoves or ranges, etc., can solve the problems of not teaching not disclosing a chamber to stabilize the flame, and achieve the effect of maintaining flame stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

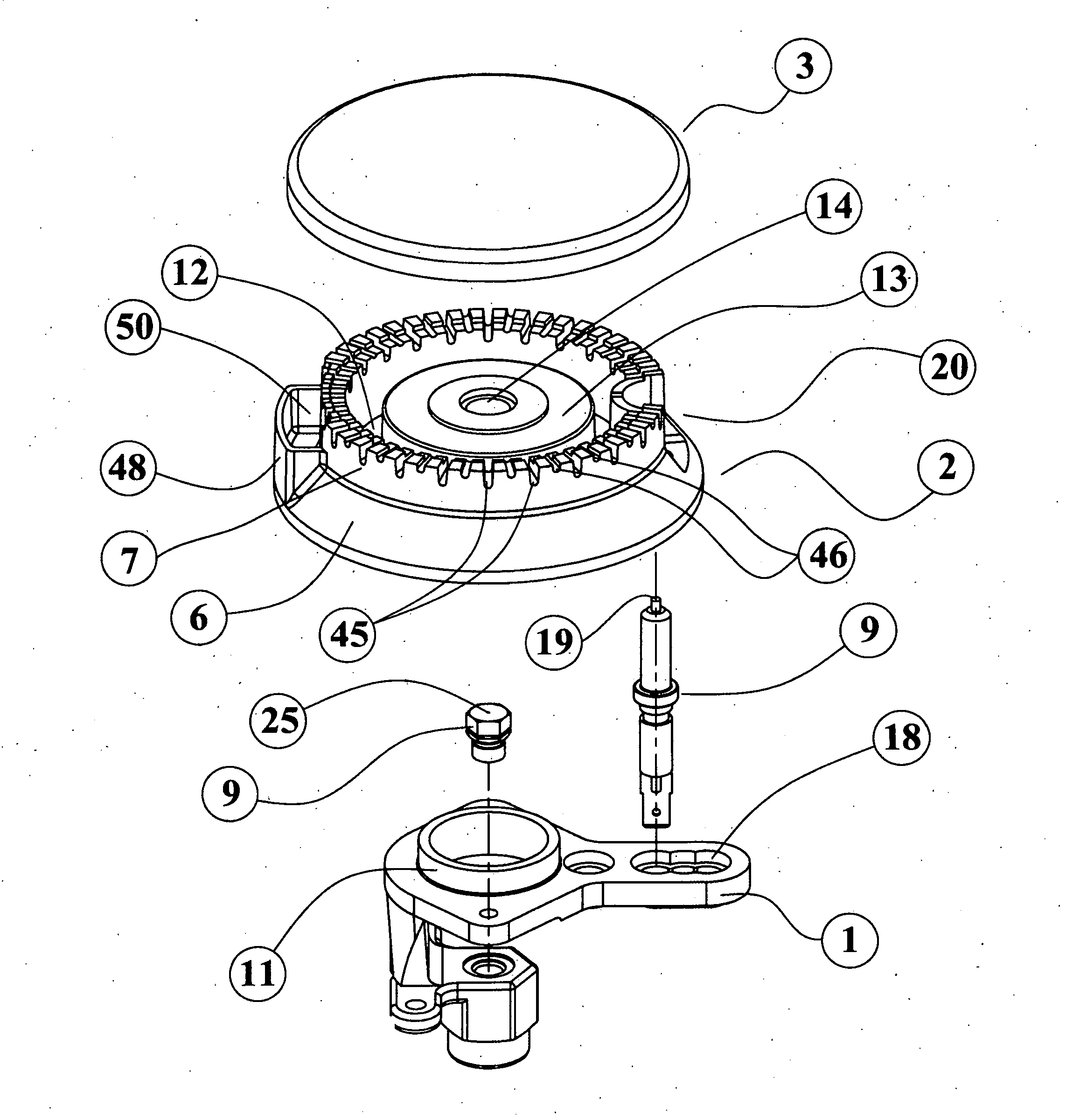

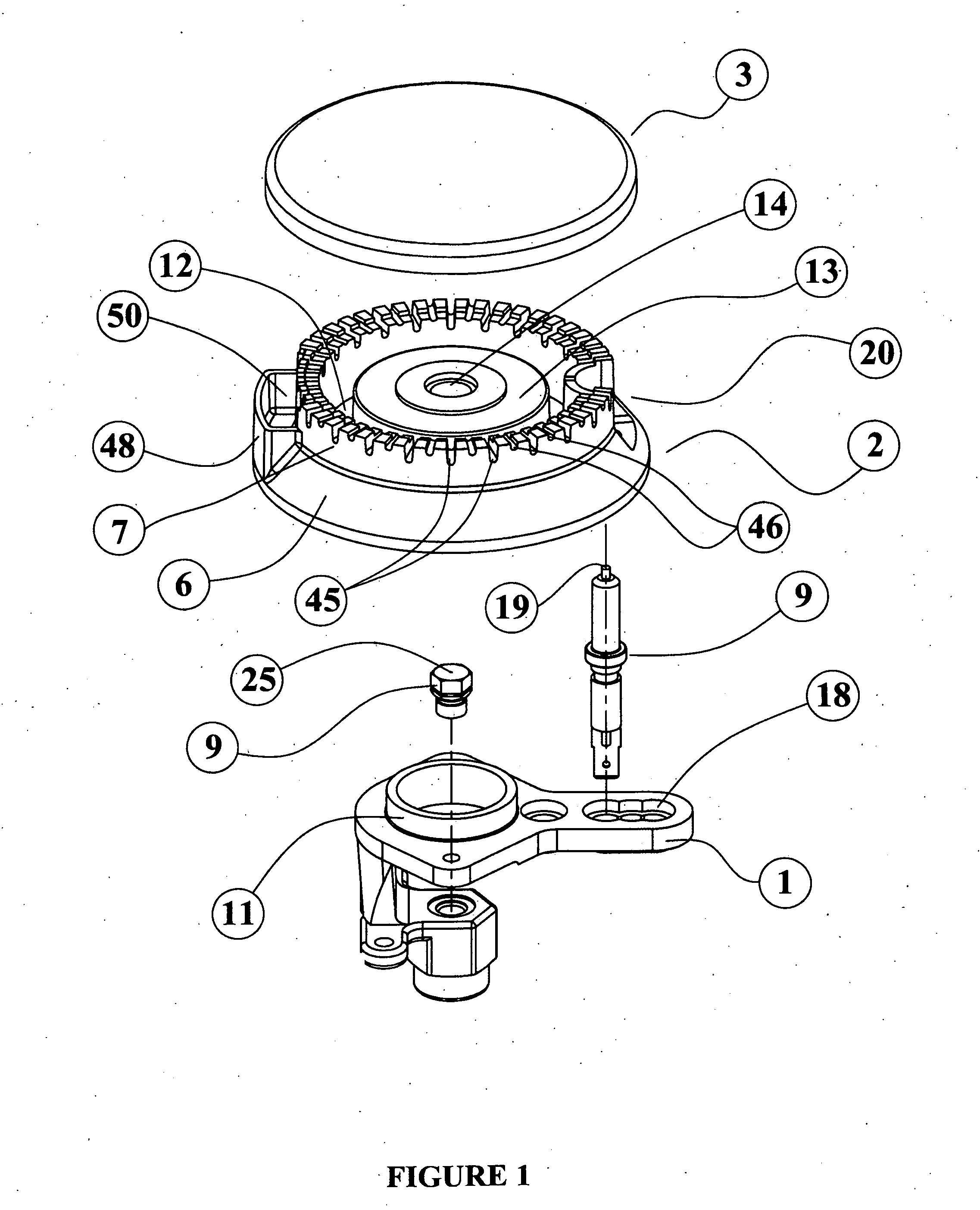

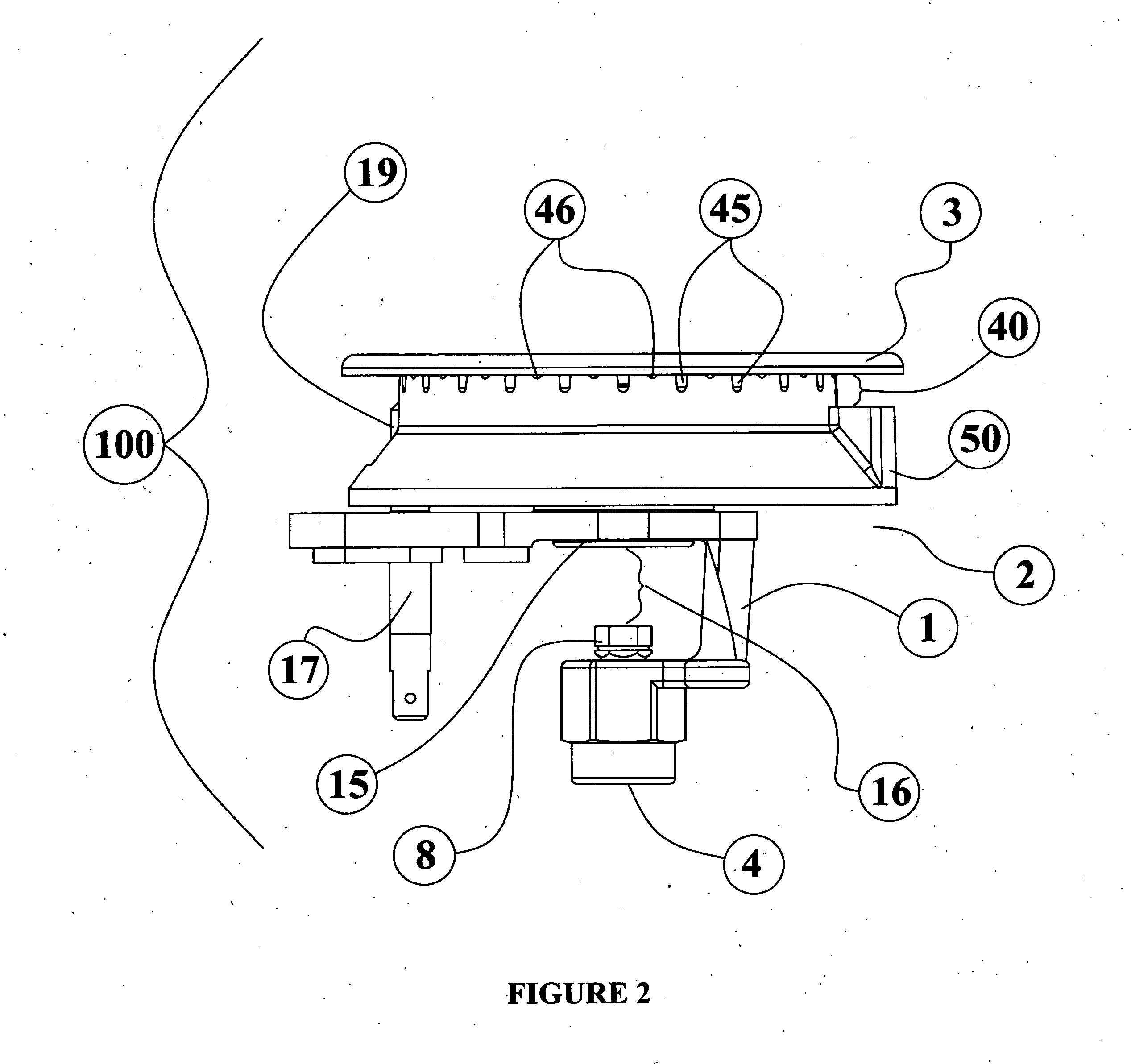

[0033]The present invention relates to a burner flame ring for a gas burner having at least one flame stabilization chamber provided therein. The flame stabilization chamber serves to retain a small amount of the gas / air mixture and preserve flame stabilization of the burner. The flame stabilization chamber is located on the outer wall of the burner flame ring. The small amount of the gas / air mixture that is caught inside the flame stabilization chamber is relatively isolated from the main burner chamber of the burner flame ring. When any gas / air flow or pressure changes occur in the ports of the burner flame ring, the gas / air mixture contained in the flame stabilization chamber is available to stabilize the flame at the ports and to preserve the correct performance of the burner.

[0034]The present invention is described with reference to the drawings and it is to be appreciated that the various drawings are not drawn to scale from one figure to another nor inside a given figure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com