Golf balls comprising thermoplastic or thermoset composition having controlled gel time

a technology of thermoplastics and compositions, applied in the field of golf balls, can solve the problems of not having resilience or light stability comparable to ionomer covers, providing inferior spin and feel to golf balls, etc., and achieves the effects of longer ball flight, higher cor, and more total energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The cover of the golf ball provides the interface between the ball and a club. Desirable properties for the cover include good moldability, high abrasion resistance, high tear strength, and high resilience. The cover generally should provide sufficient strength for good performance characteristics and durability. The cover may have a single-layer construction, or a multi-layer construction that includes one or more inner cover layers and an outer cover layer. The material compositions described herein, while applicable in any portion of the golf ball, are preferably used to form cover layer(s), including single-layer covers, inner cover layers, and / or outer cover layers.

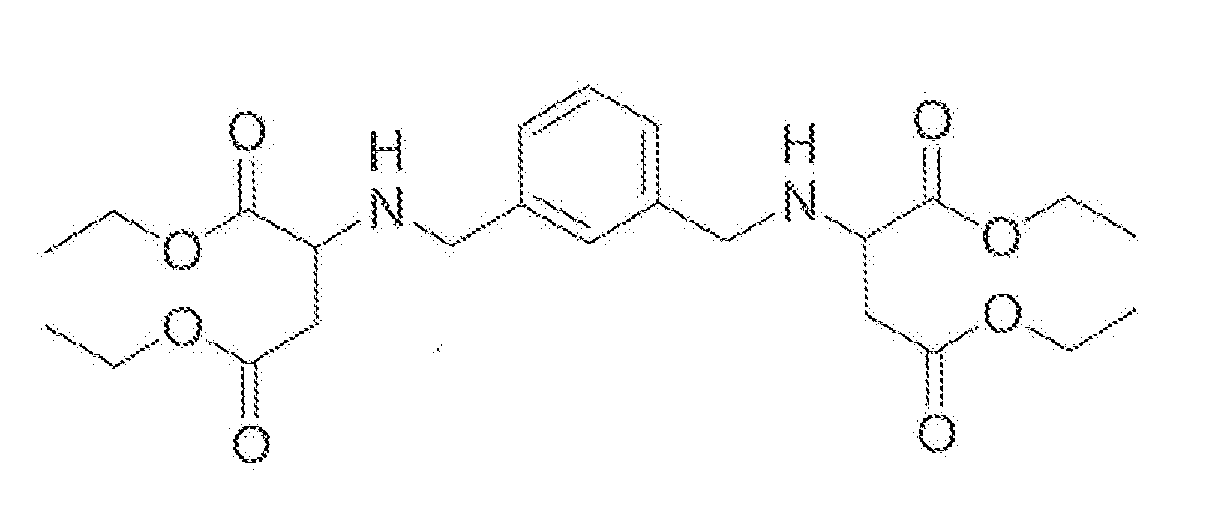

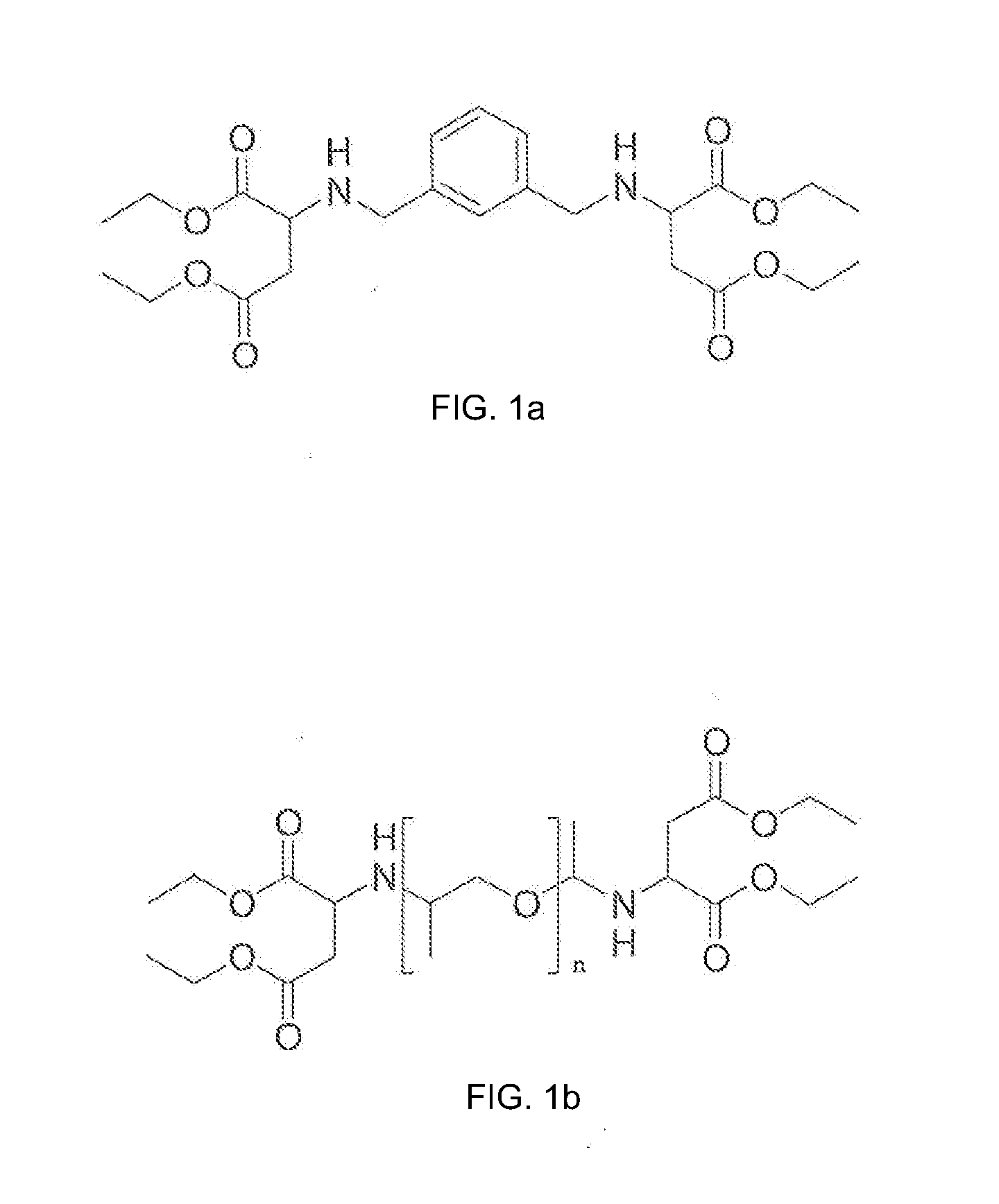

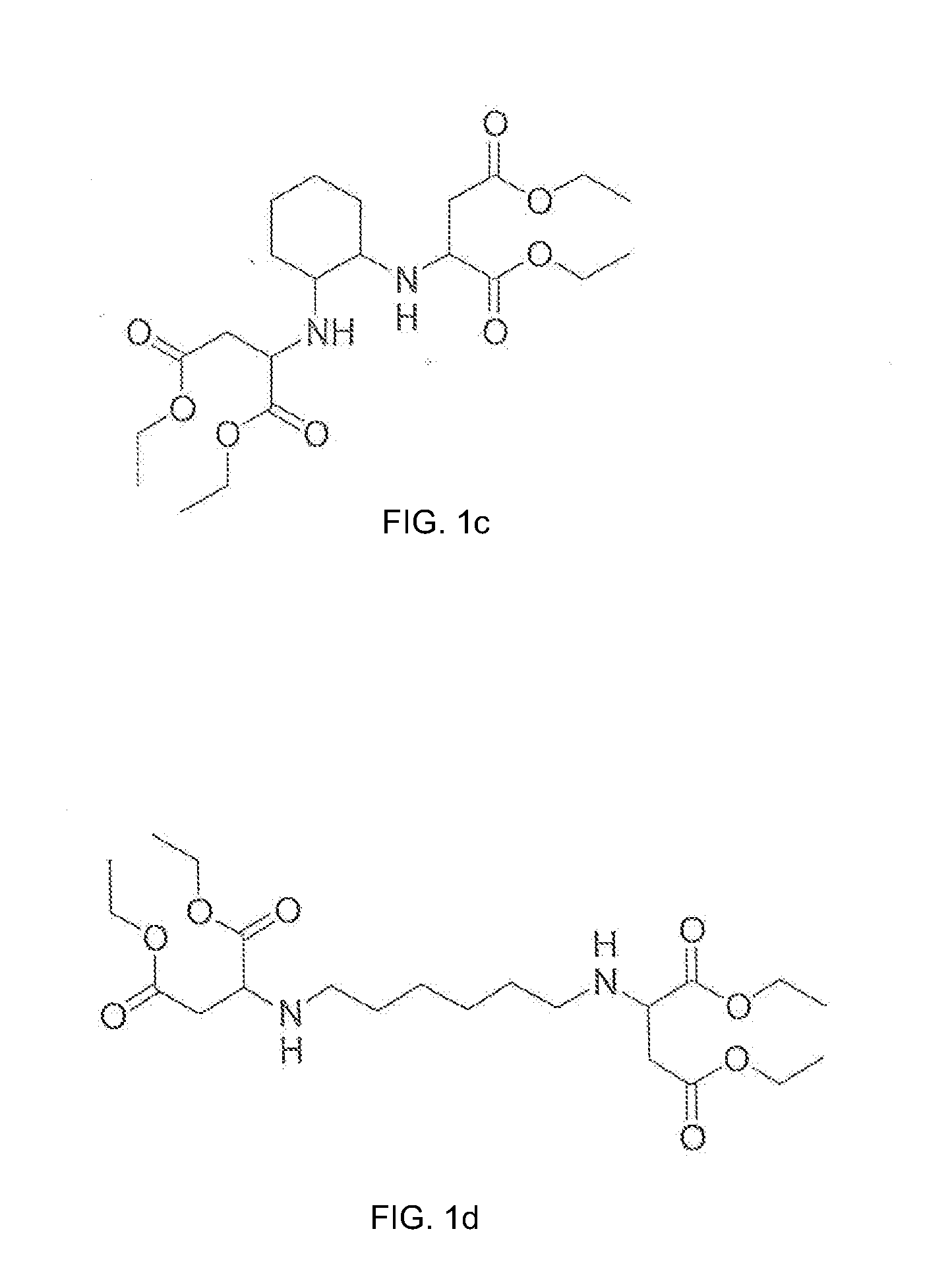

[0048]The cover layer, particularly the outer cover layer, of the present invention may comprise about 1 weight percent to about 100 weight percent, preferably about 5 weight percent to about 95 weight percent, of a thermoplastic or thermoset composition. The composition, preferably formed from a castable liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com