Removable trigger guard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

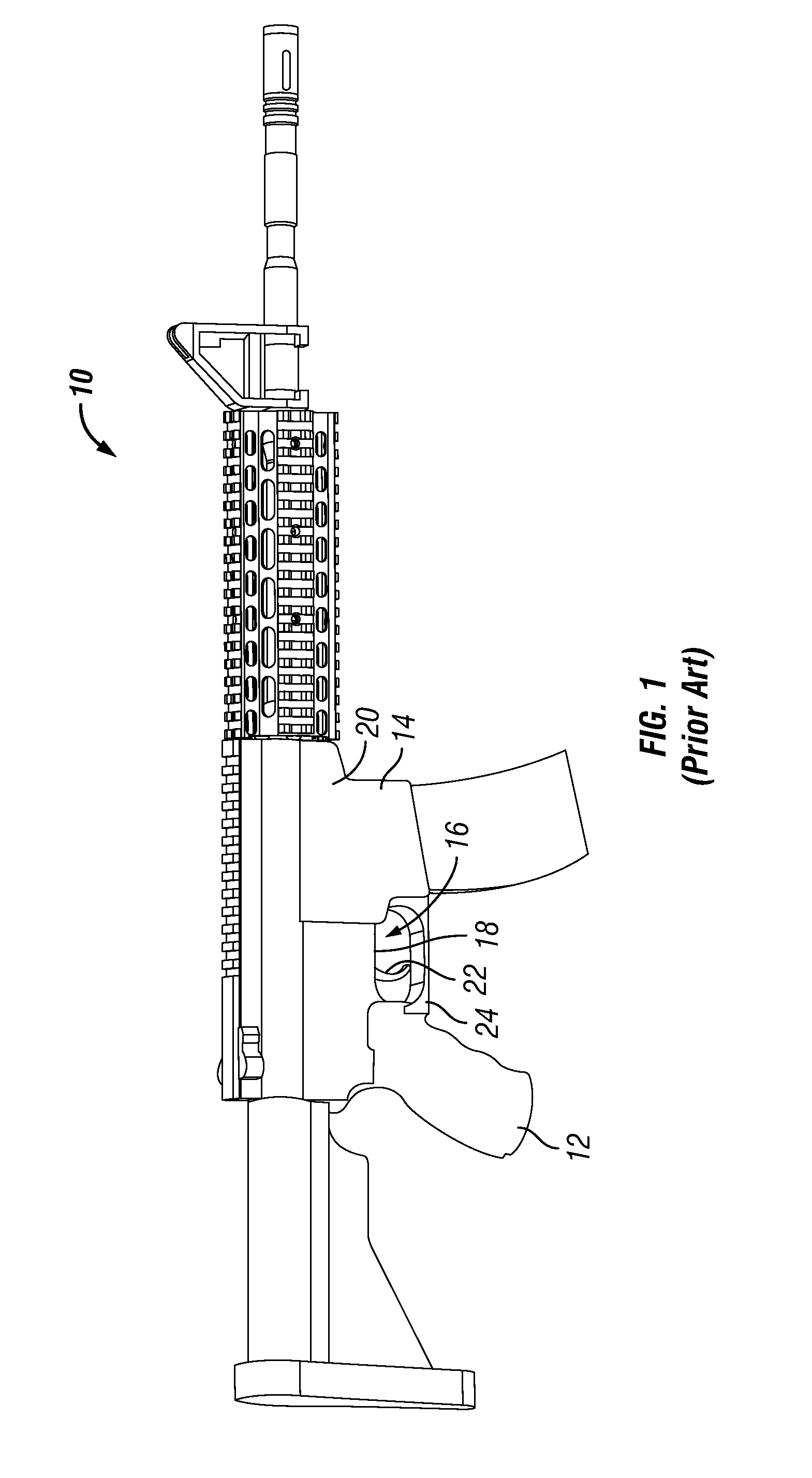

[0032]Referring to FIG. 1, a firearm 10 according to the prior art, such as a M-16 style firearm, is shown. The firearm 10 has a grip 12 and a magazine well 14 that, together, define a trigger space 16 disposed adjacent to a partly-opened lower surface 18 of a receiver 20 of the firearm 10. The grip 12 commonly is mounted to the receiver 20, while the magazine well 14 may be formed integral with or as a part of the receiver 20. The receiver 20 houses a trigger mechanism (not shown in FIG. 1) that is operable by a trigger 22, which protrudes through the lower surface 18 of the receiver 20 into the trigger space 16. The firearm 10 also has a trigger guard 24 disposed between the grip 12 and the magazine well 14 to define and enclose the trigger space 16. The trigger guard 24 prevents actuation of the trigger 22 by inadvertent insertion of an object or finger into the trigger space 16.

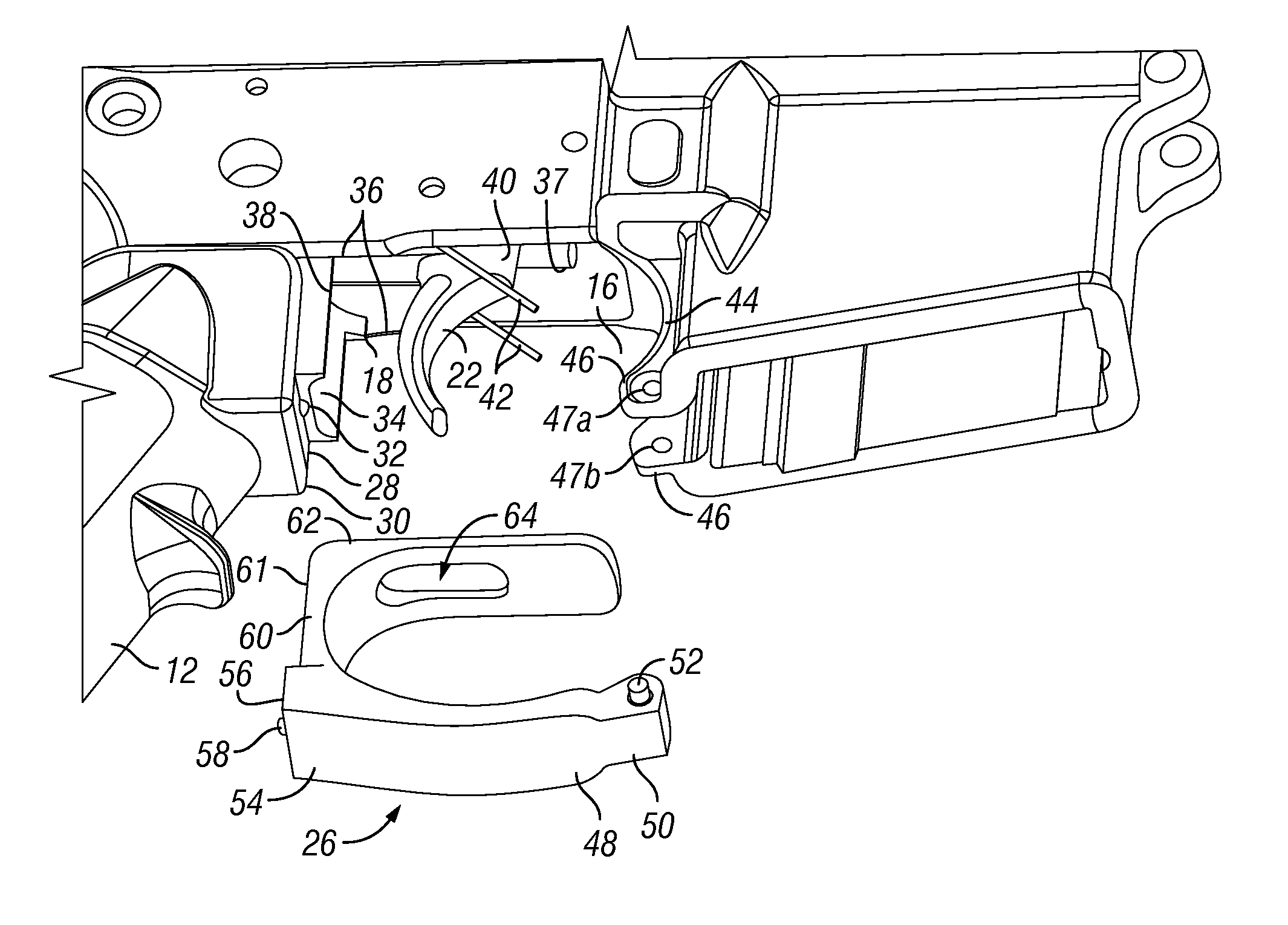

[0033]Referring to FIG. 2, the trigger space 16 is shown with a removable trigger guard 26, according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com