Shrink sleeve for an article closure

a technology for wrapping sleeves and articles, applied in the field of wrapping sleeves for containers, can solve the problems of label adhesive to the side surface of the closure, label decoration, and various reasons that have not been applied to the side of the closure, and achieve the effect of easy volatilization, greater torsional force, and added aesthetics of the label

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

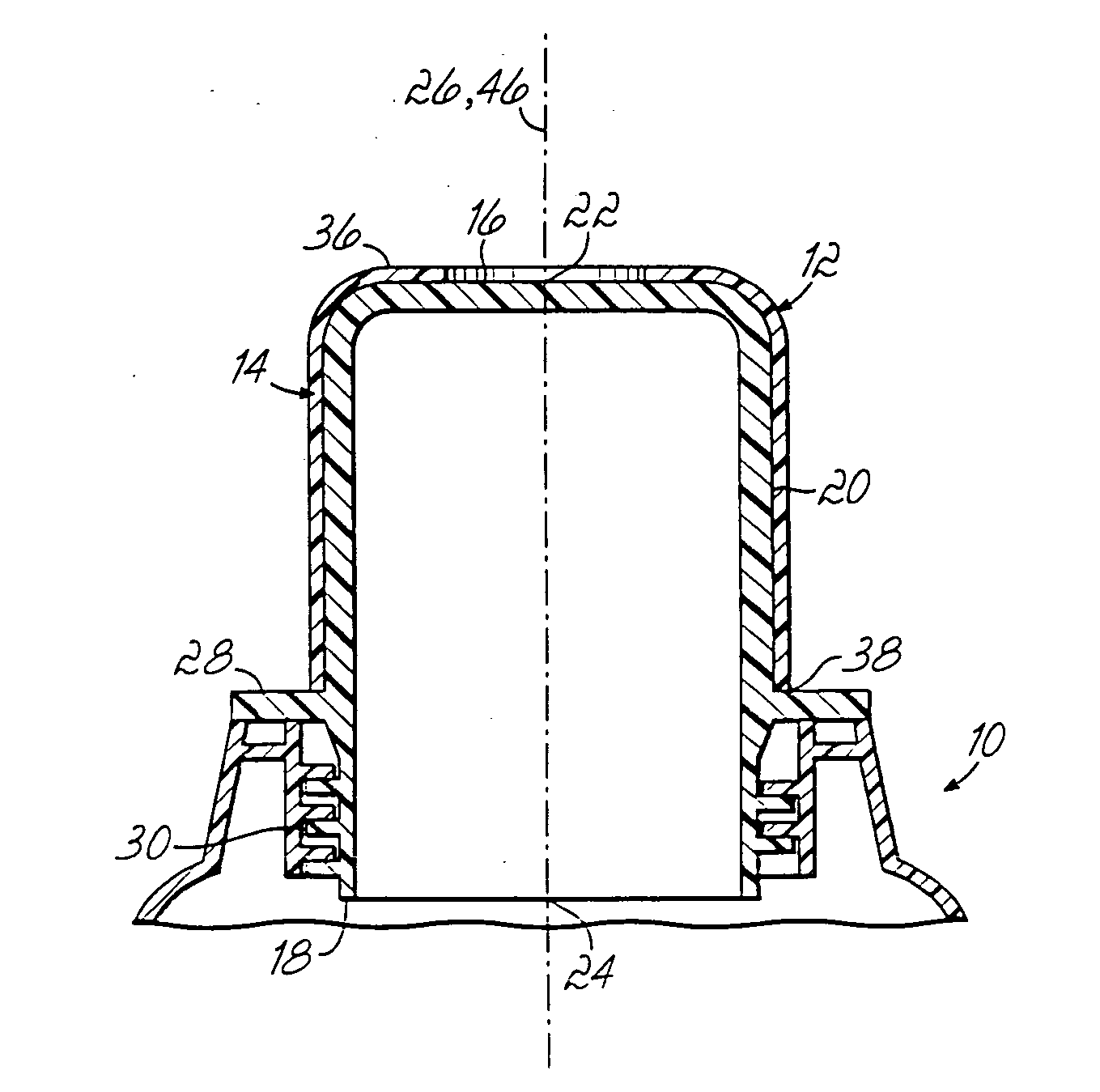

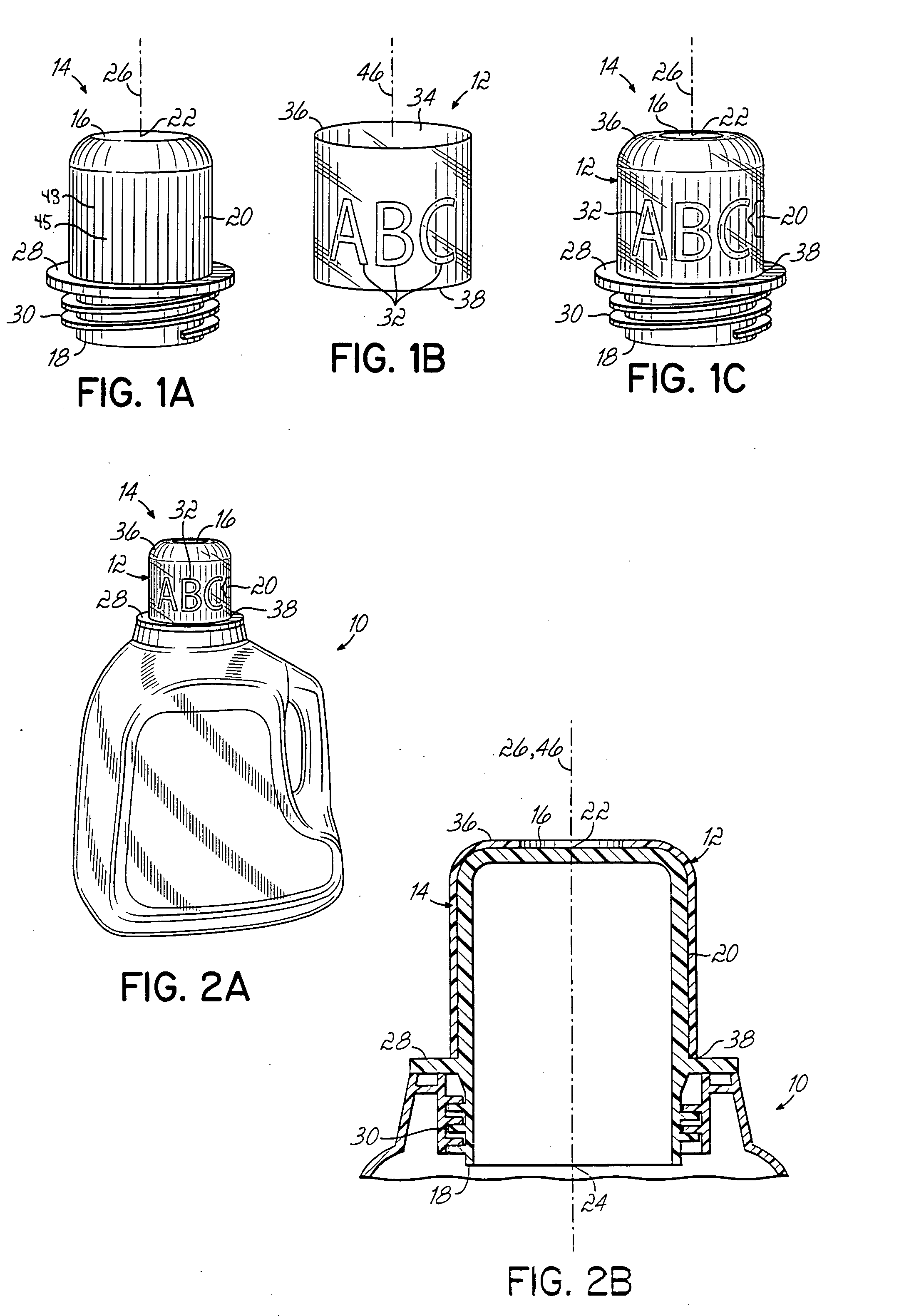

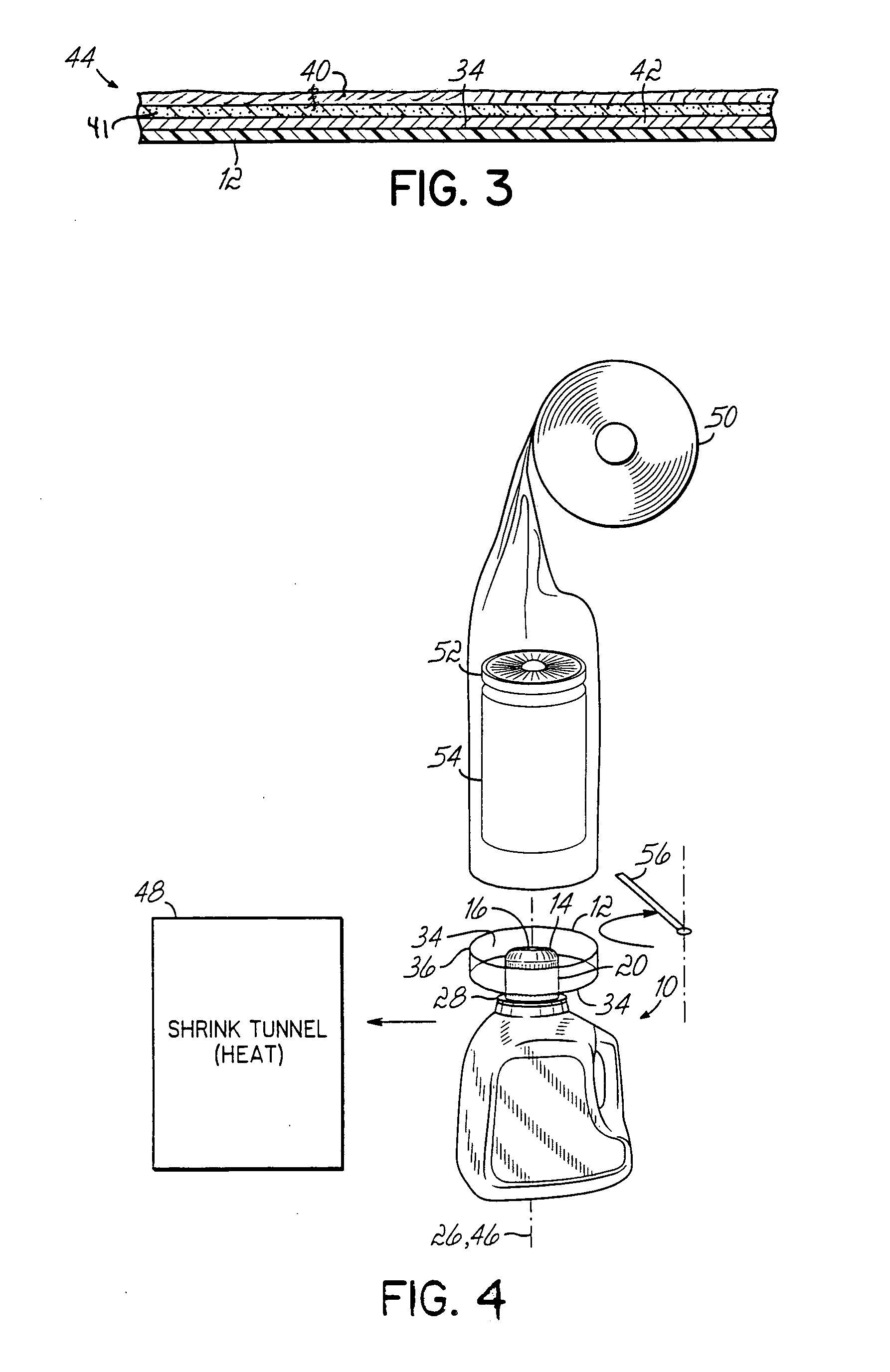

[0029] Referring now to the Figures, the present invention provides a labeled article 10 for packaging an item or items. This labeled article 10 includes a shrink sleeve 12 and an article 10 including a closure 14. In particular, and referring to FIGS. 1A-1C, in a first aspect, the present invention provides a decorated closure 14 for an article 10, such as a container used to package an item or items. The decorated closure 14 includes a shrink sleeve 12 and a closure 14 for an article 10. The closure 14 has a top end 16, a bottom end 18, and a side surface 20. The closure 14 may further include a centerpoint 22 of the top end 16 and a centerpoint 24 of the bottom end 18 with a longitudinal axis 26 passing therethrough. As shown in FIG. 1A, the closure 14 includes a flange 28 and screw threads 30 proximal its bottom end 18. It should be recognized that the closure 14 including flange 28 and screw threads 30 is merely exemplary, and any type of closure 14 may be used.

[0030] As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com