Inner bladder structure for ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

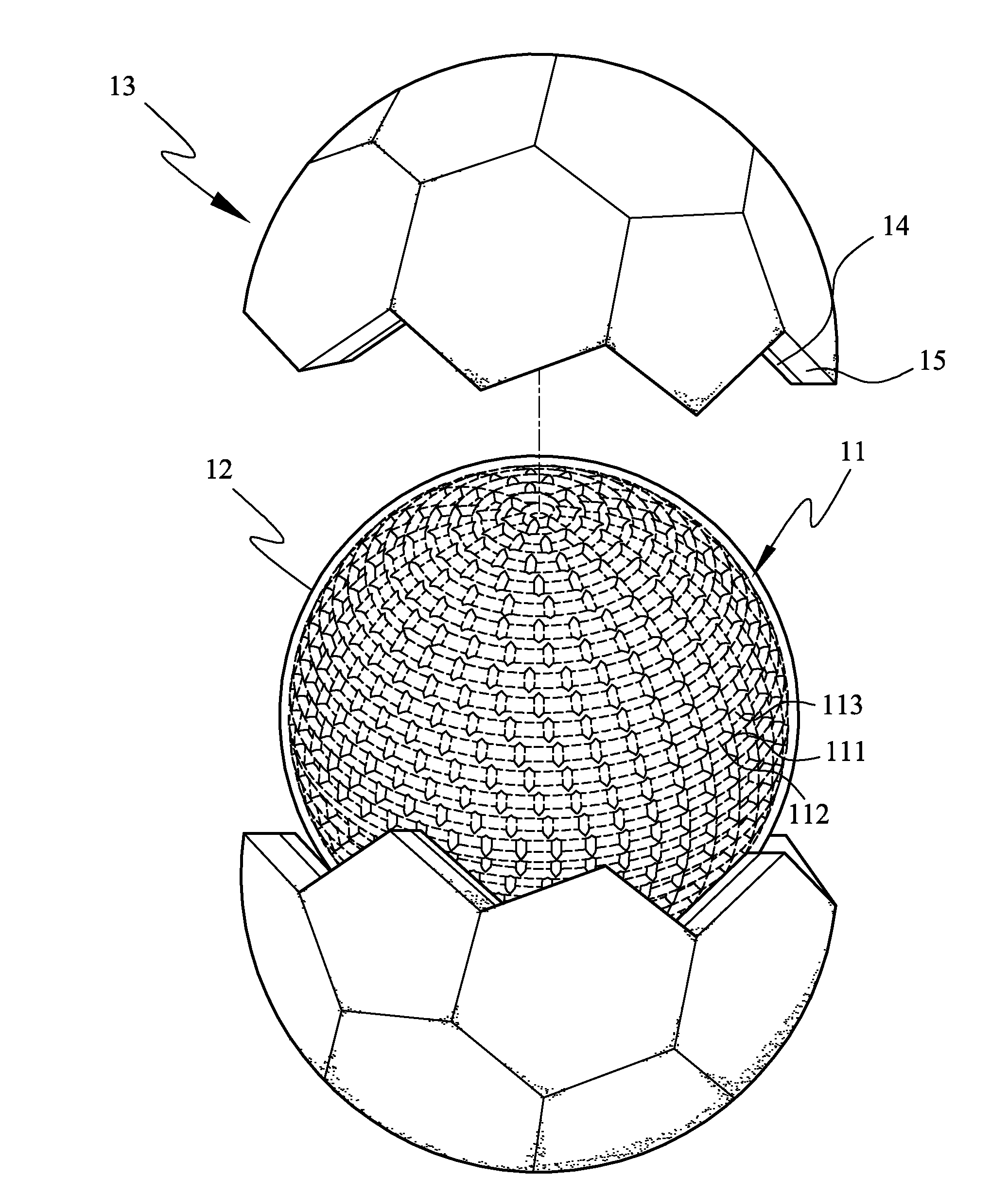

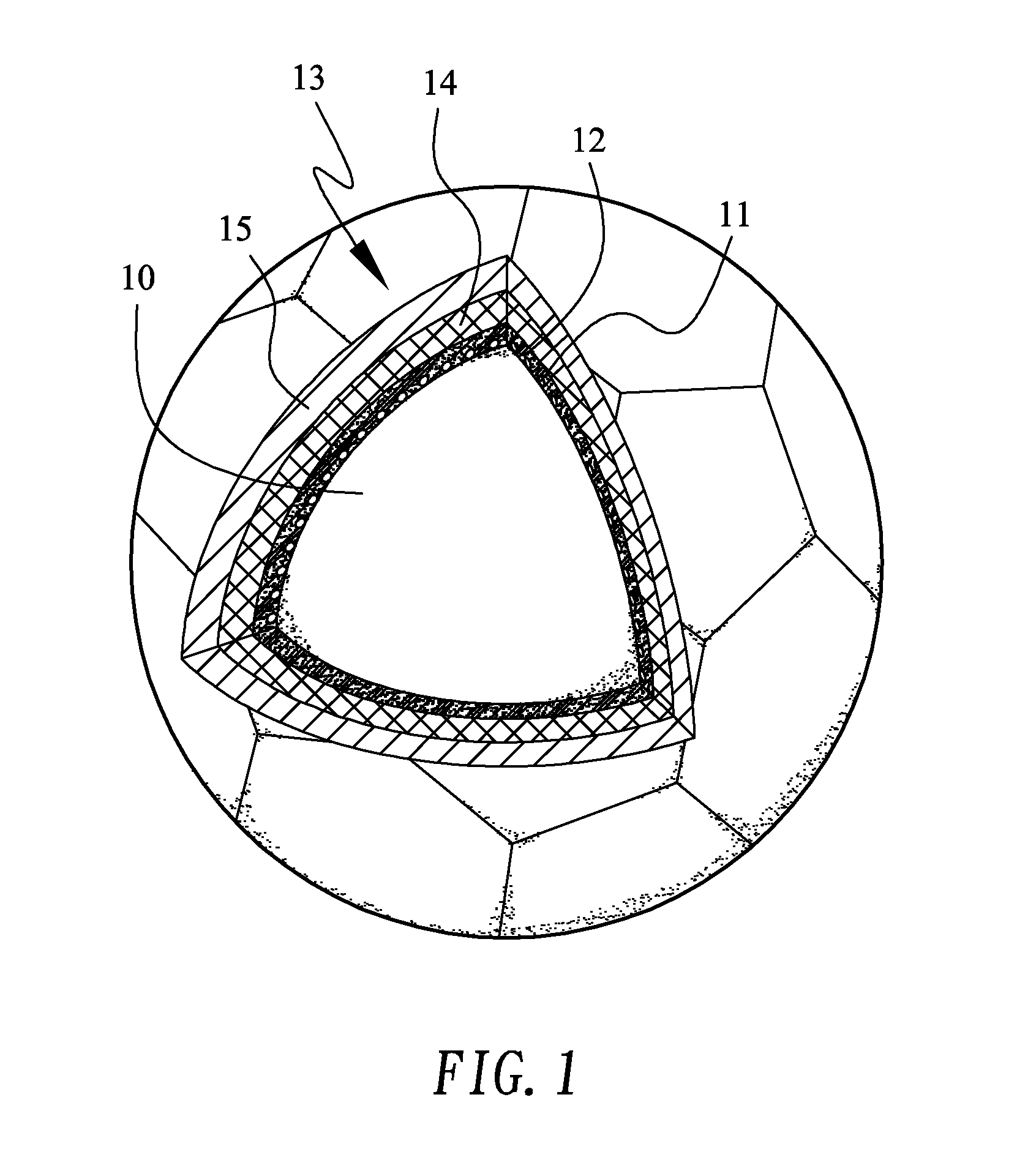

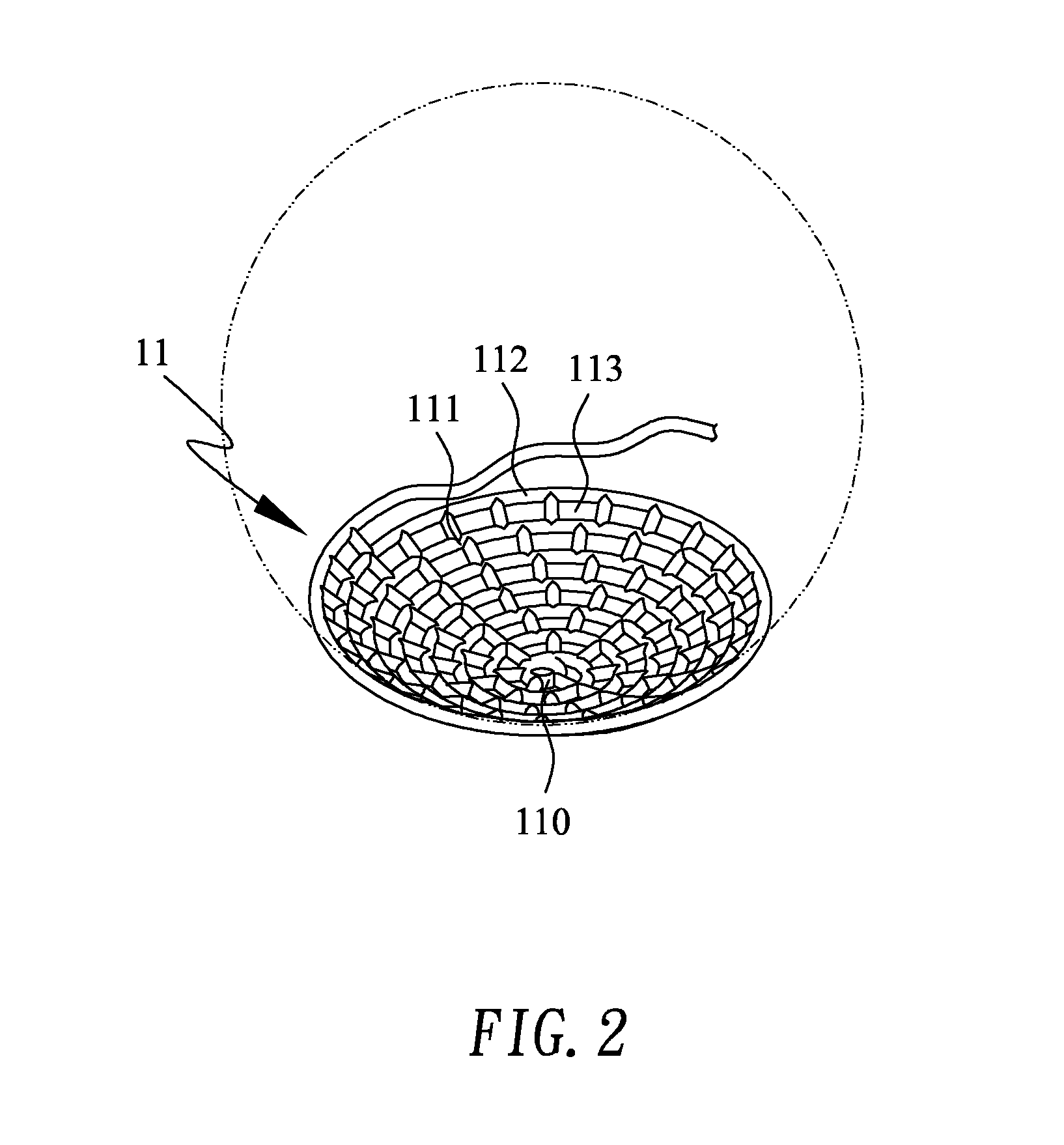

[0030]Please refer to FIG. 2. In the present invention, the yarn layer 11 is a single-layered web structure integrally knitted using knitting yarns 112 to have a three-dimensional (3D) spherical shape, so that the web structure bearing on an outer surface of the bladder 10 has minimized seams. A plurality of voids 113 is formed between adjacent knitting yarns 112, so that the knitting yarns 112 subjected to an externally applied force are displaceable relative to one another, allowing the web structure to finely adjust its surface shape and completely bear against the outer surface of the bladder 10 to ensure the highest possible roundness of the bladder 10. The emulsion layer 12 fills up all the voids 113 on the yarn layer 11 to form a smooth spherical body.

[0031]In a preferred embodiment, the web structure of the yarn layer 11 is formed by knitting the yarns 112 around the bladder 10 from a predetermined starting point 110 on the outer surface of the bladder 10, so that the web st...

second embodiment

[0035]Please refer to FIG. 8. According to the present invention, the yarn layer 11 is in the form of a spherical-shaped knitted fabric 20. The spherical-shaped knitted fabric 20 is formed by knitting yarns at a fixed spacing around an axis of a preset spherical surface, which has a radius corresponding to that of the bladder 10, and the knitting is started from a preset one of the longitudes of the preset spherical surface. The spherical-shaped knitted fabric 20 is knitted using an elastic 3D knitting technique, and has a locating section 21 formed at each of two opposing edges thereof. A releasable connecting yarn 22 is provided between each of the locating sections 21 and the spherical-shaped knitted fabric 20 to form a separable joint 221 thereat, so as to facilitate later separating of the locating sections 21 from the spherical-shaped knitted fabric 20.

[0036]FIG. 9 is an enlarged view of the circled area A of FIG. 8. As shown, in the illustrated second embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com