Laying and mechanically joining building panels or construction elements

a technology for building panels and construction elements, applied in mechanical apparatus, building repairs, fastening means, etc., can solve problems such as loss of saleable panel surface materials, and achieve the effect of cost saving and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

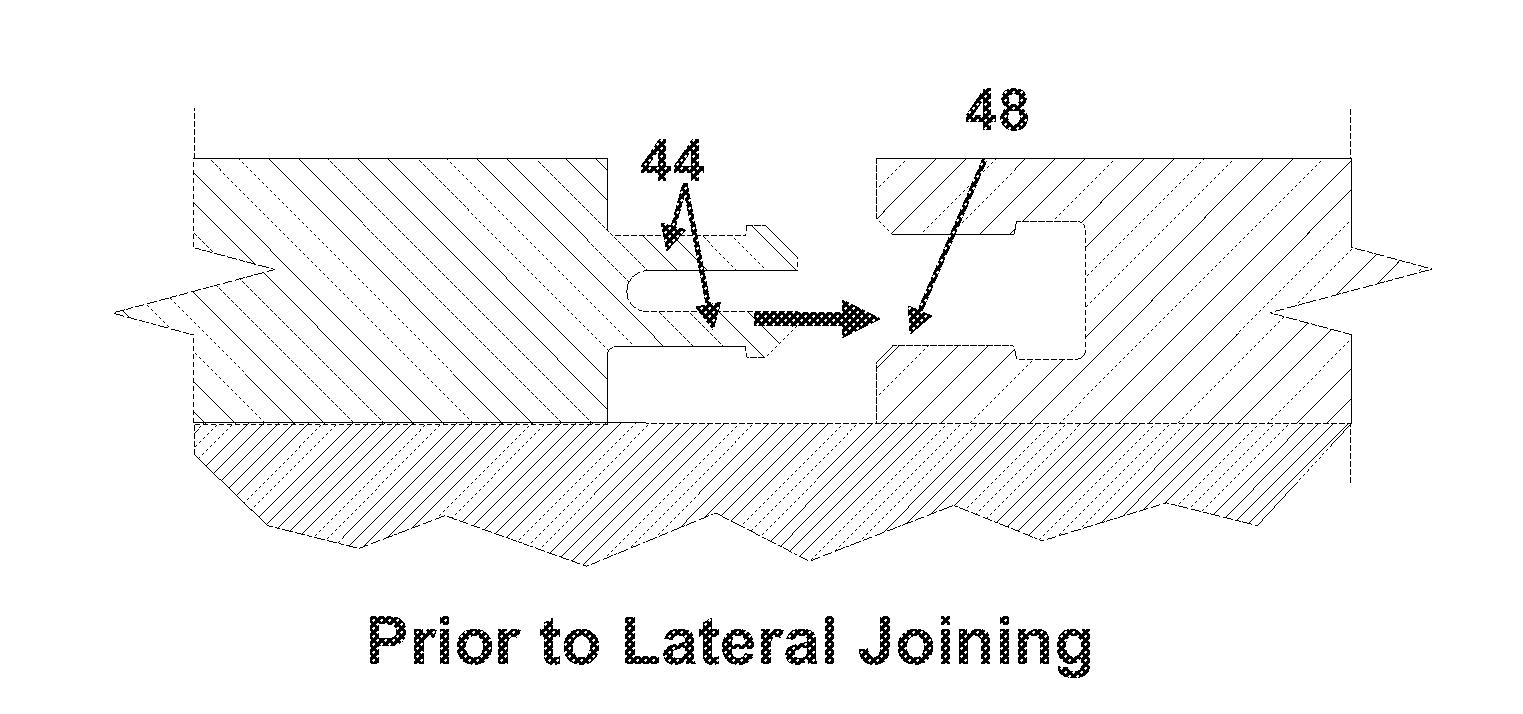

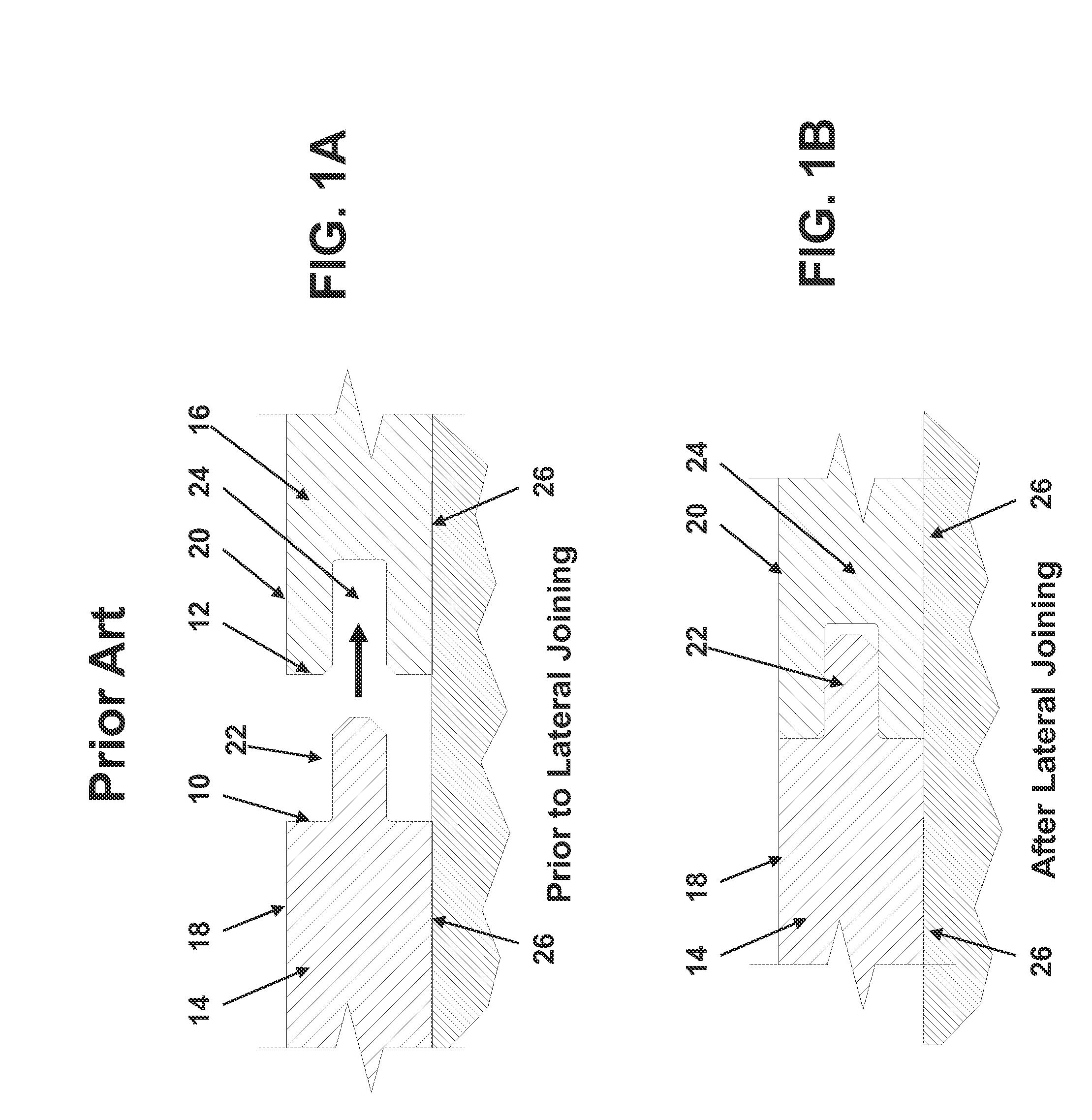

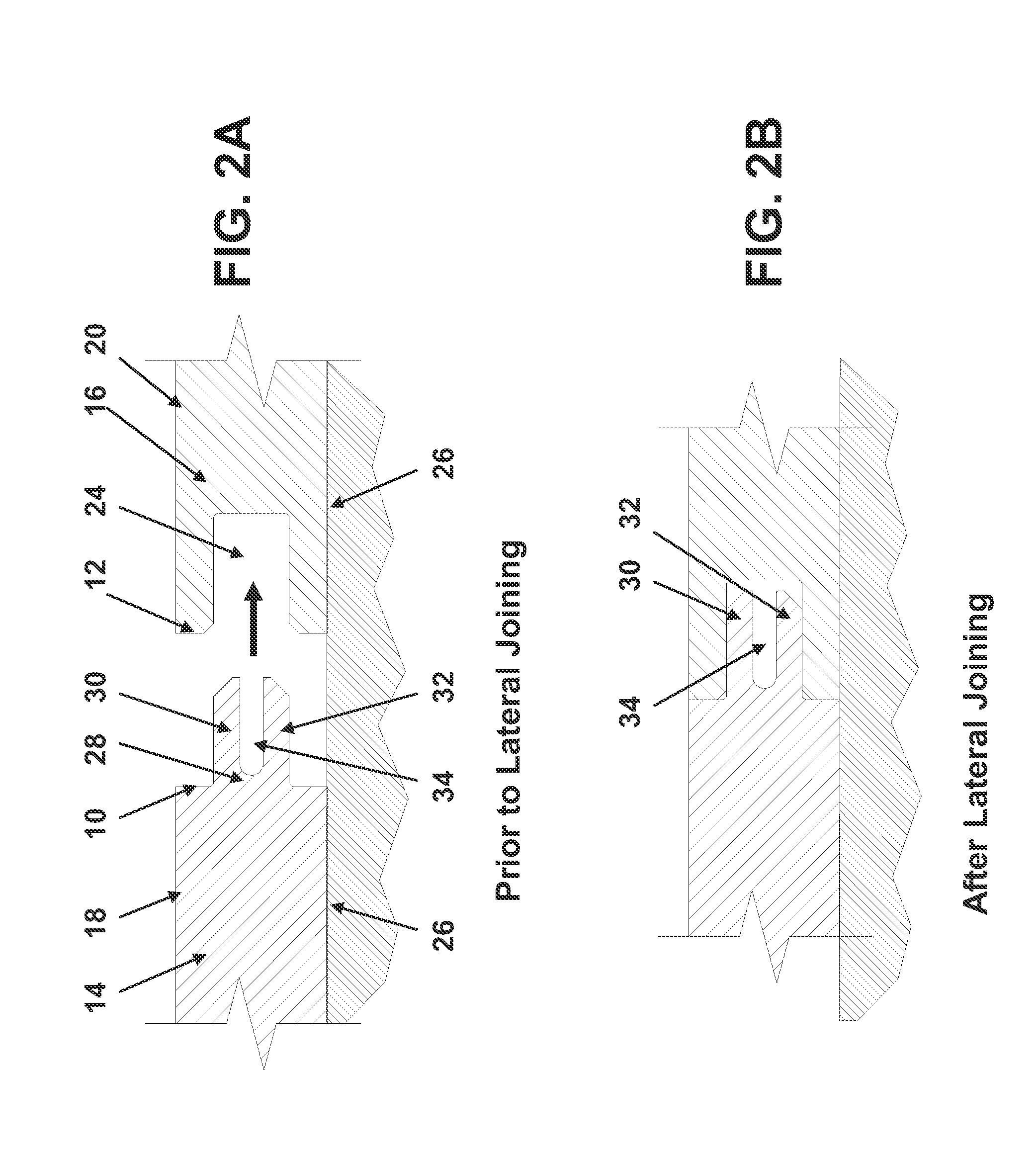

[0057]Referring to FIGS. 1A and 1B, there are shown side views of a prior art tongue and groove joint prior to and after being joined together with lateral insertion. Typically, the adjacent edges 10, 12 of building panels 14, 16 must be held in good alignment normal to the panel faces 18, 20, e.g., in floating laminate flooring, so that the assembled panels appear to form a contiguous flat front or top surface. This alignment and holding is typically achieved by means of a tongue 22 and groove 24 joint. In many cases the holding feature of the tongue to its groove is accomplished solely by friction between the tongue and groove surfaces, while in other instances the holding action can be augmented with the use of adhesives or by shaping the tongue and its mating groove to provide a mechanical locking feature.

[0058]The panels used in flooring typically have two relatively flat surfaces: the upper surface 18, 20, which is the surface typically walked on, and a lower surface 26, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| structures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com