Method for producing a screw foundation

a production method and screw technology, applied in the field of screw foundation production methods, can solve the problems of high production complexity, weak durability and strength, and achieve the effects of low internal stress, high loading capacity of the screw foundation, and efficient and precise procedural sequen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005]It is therefore the object of the present invention to provide a method for producing a screw foundation which enables a simple production process while minimising weaknesses.

[0006]This object is achieved according to the invention by a method for producing a screw foundation according to claim 1. Particularly advantageous further developments of the invention are specified in the dependent claims.

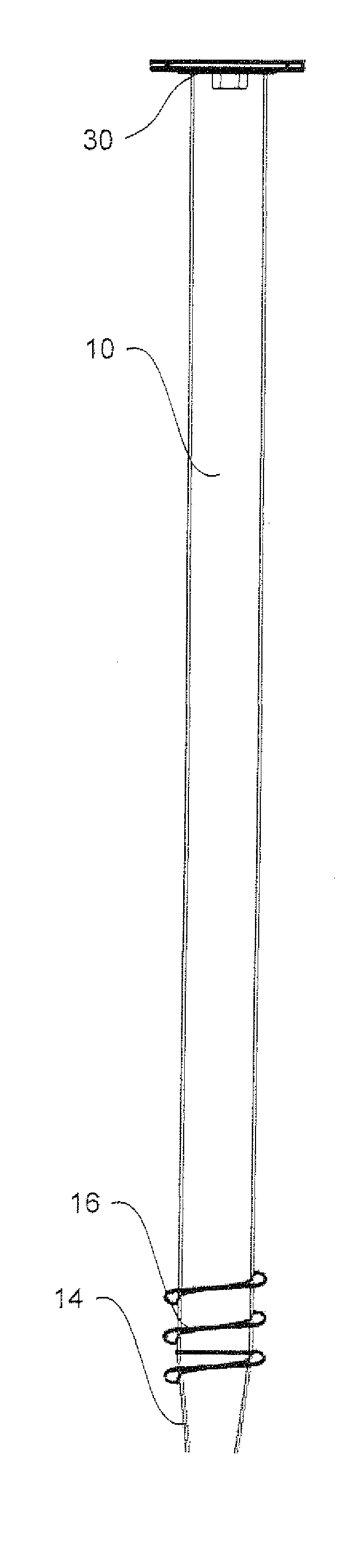

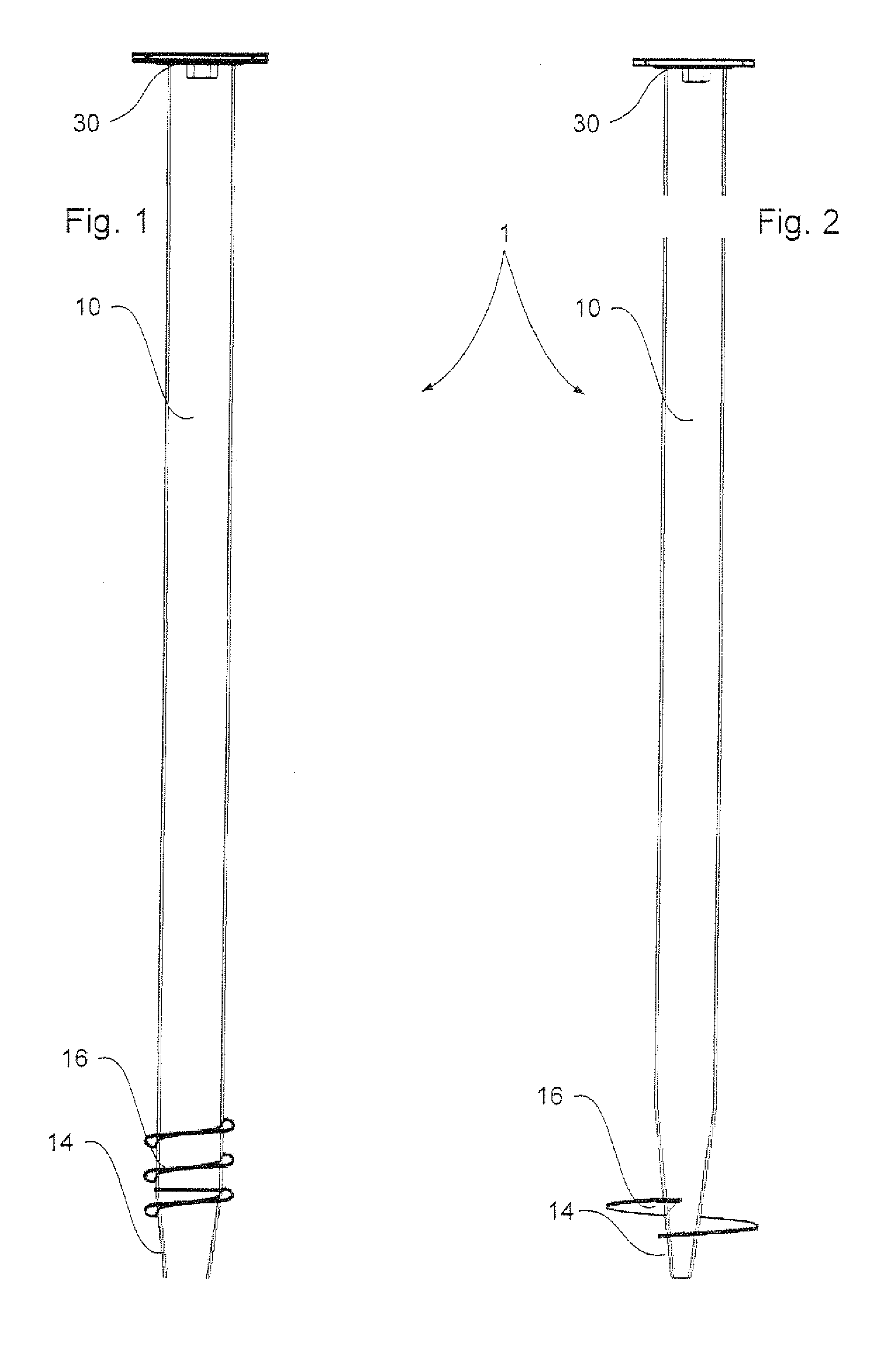

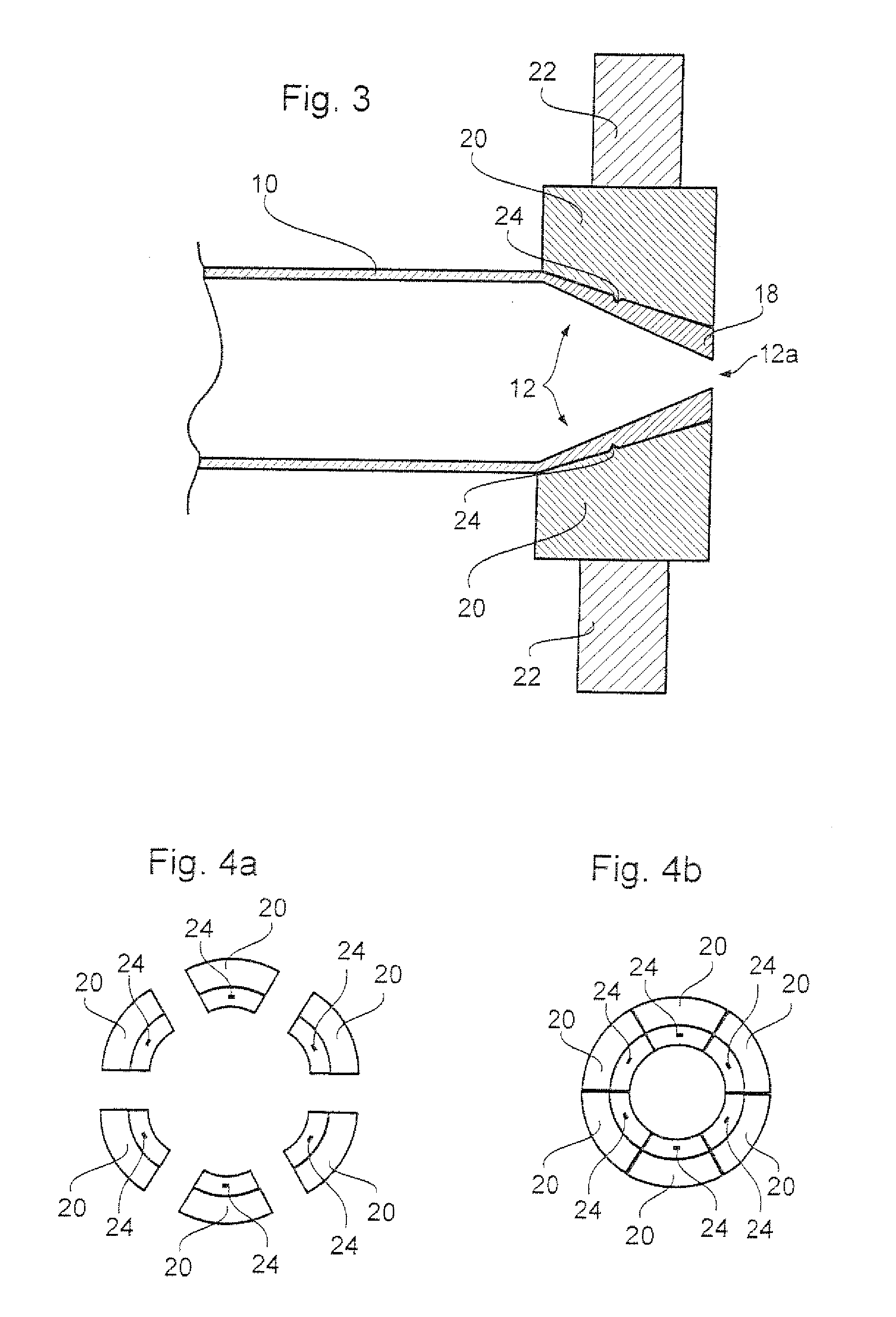

[0007]The idea forming the basis of the invention is, with a method for producing a screw foundation, to reduce the number of procedural steps directly affecting the later screw foundation such that not only is a simplified procedural sequence produced, but at the same time also a reduced number of interfaces and so of weak points. Against this background the method according to the invention comprises the following steps:[0008]providing a tubular starting material with a required length,[0009]laying a free end of the tubular starting material between at least two shaped elements,[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| durability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com