Automatic grease dispensing monitoring and alarm system

a technology of automatic grease dispensing and alarm system, which is applied in the direction of lubricant level maintenance, signal processing, lubrication indication devices, etc., can solve the problems of difficulty in accurately checking the amount of lubricating grease in an enclosed lubrication point, difficulty in controlling the amount of lubricating grease dispensing for each lubricating point or estimating the supply, and maintenance of lubricating points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

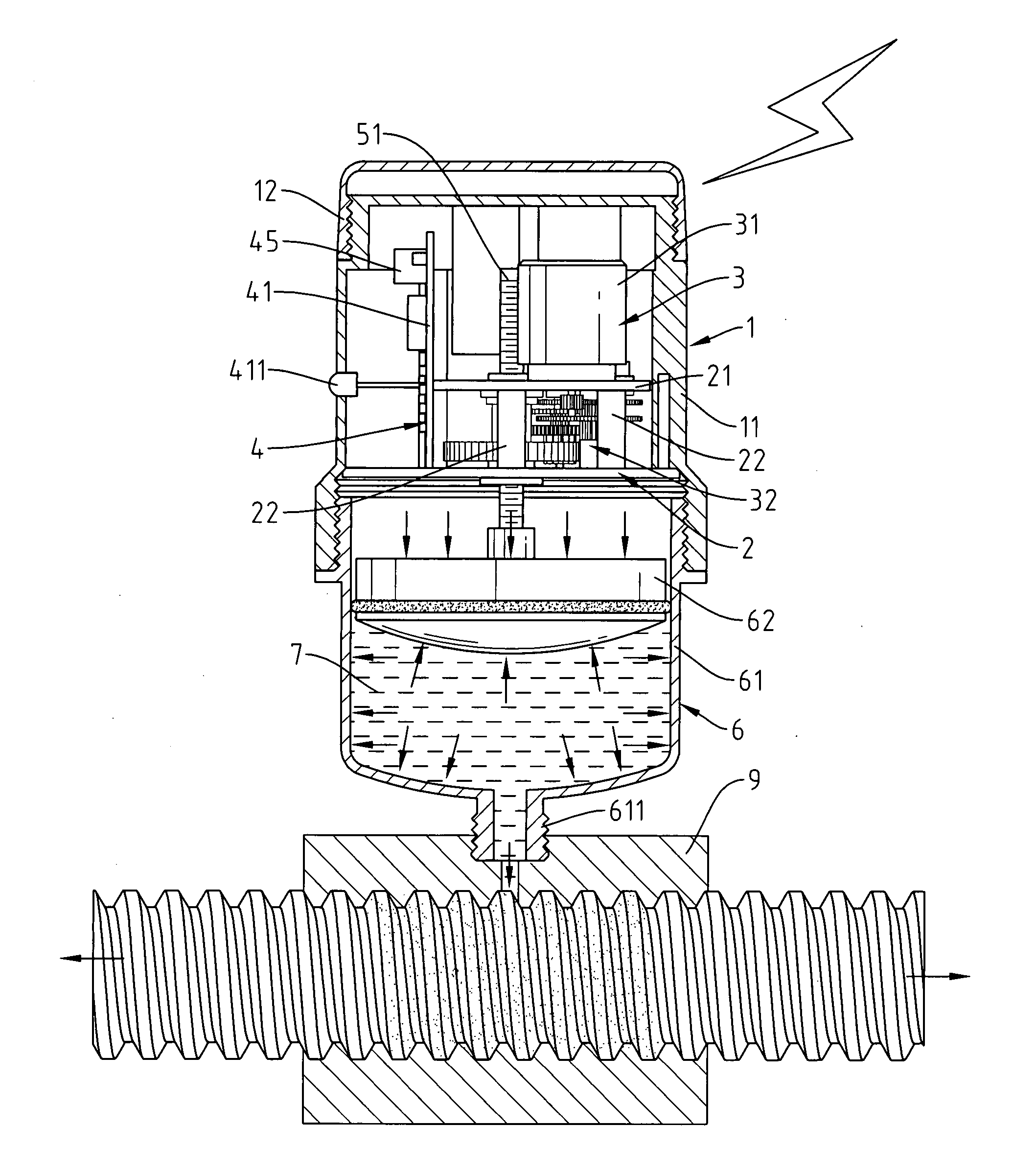

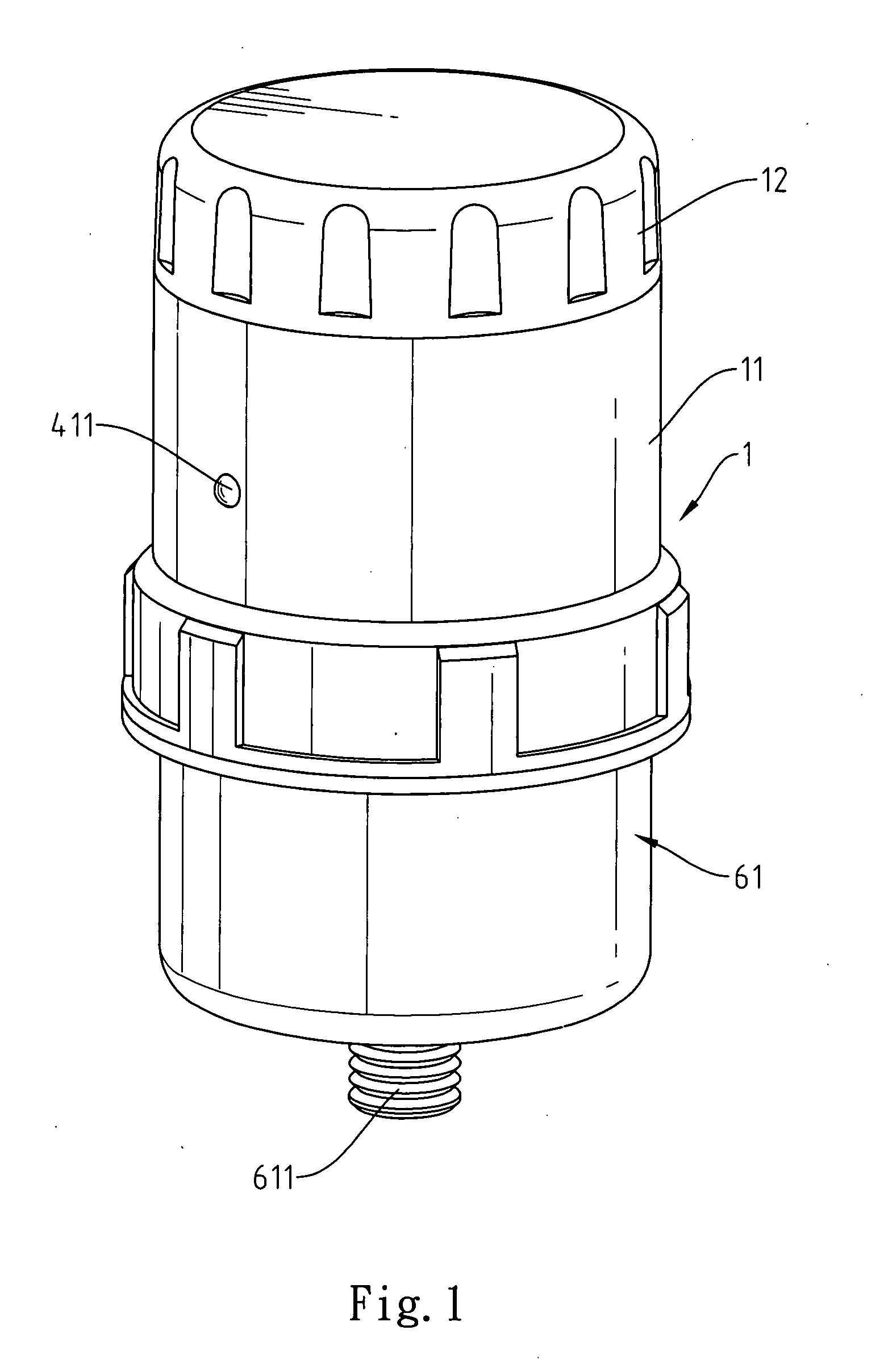

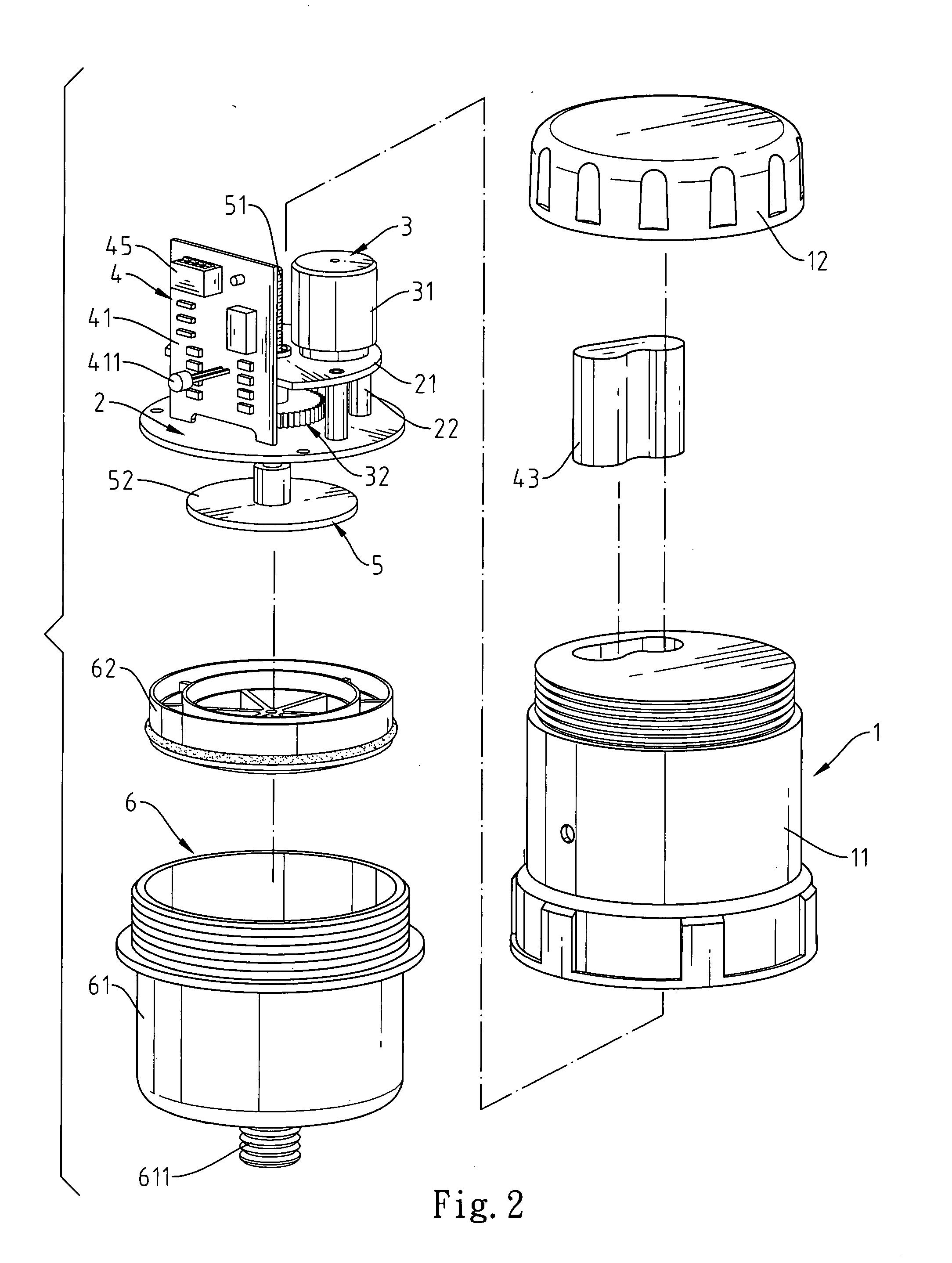

[0023]Referring to FIGS. 1-3, an automatic grease dispenser in accordance with the present invention is shown comprised of a housing 1, a holder frame 2, a driving mechanism 3, a control unit 4, a propelling device 5, and a grease container 6. The bottom side of the body 11 of the housing 1 is an open side. The top side of the body 11 is configured to accommodate a battery 43 of the control unit 4. Further, a top cap 12 is threaded onto the top side of the body 11 to hold down the battery 43.

[0024]The holder frame 2 is fixedly mounted in the body 11 of the housing 1 to block the grease container 6 from parts disposed at the top side of the holder frame 2, comprising a plurality of upright supports 22, a top mount 21 affixed to the upright supports 22 at the top.

[0025]The driving mechanism 3 comprises a motor 31 fixedly mounted on the top mount 21, a speed reducing gear set 32 installed in the holder frame 2 below the top mount 21 and surrounded by the upright supports 22 and coupled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com