Method for producing sterile cryogenic liquid

a cryogenic liquid and cryogenic liquid technology, applied in the direction of lighting and heating apparatus, filtration, solidification, etc., can solve the problems of difficult pre-sterilization of the system, complicated piping and valves, etc., and achieve the effect of rapid sterilization with steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The present invention provides for optimizing the discharge rate of a sterile cryogenic fluid from a sterile cryogenic fluid production process by determining the optimum discharge orifice size based upon a predetermined flow rate and pressure of the sterile cryogenic fluid.

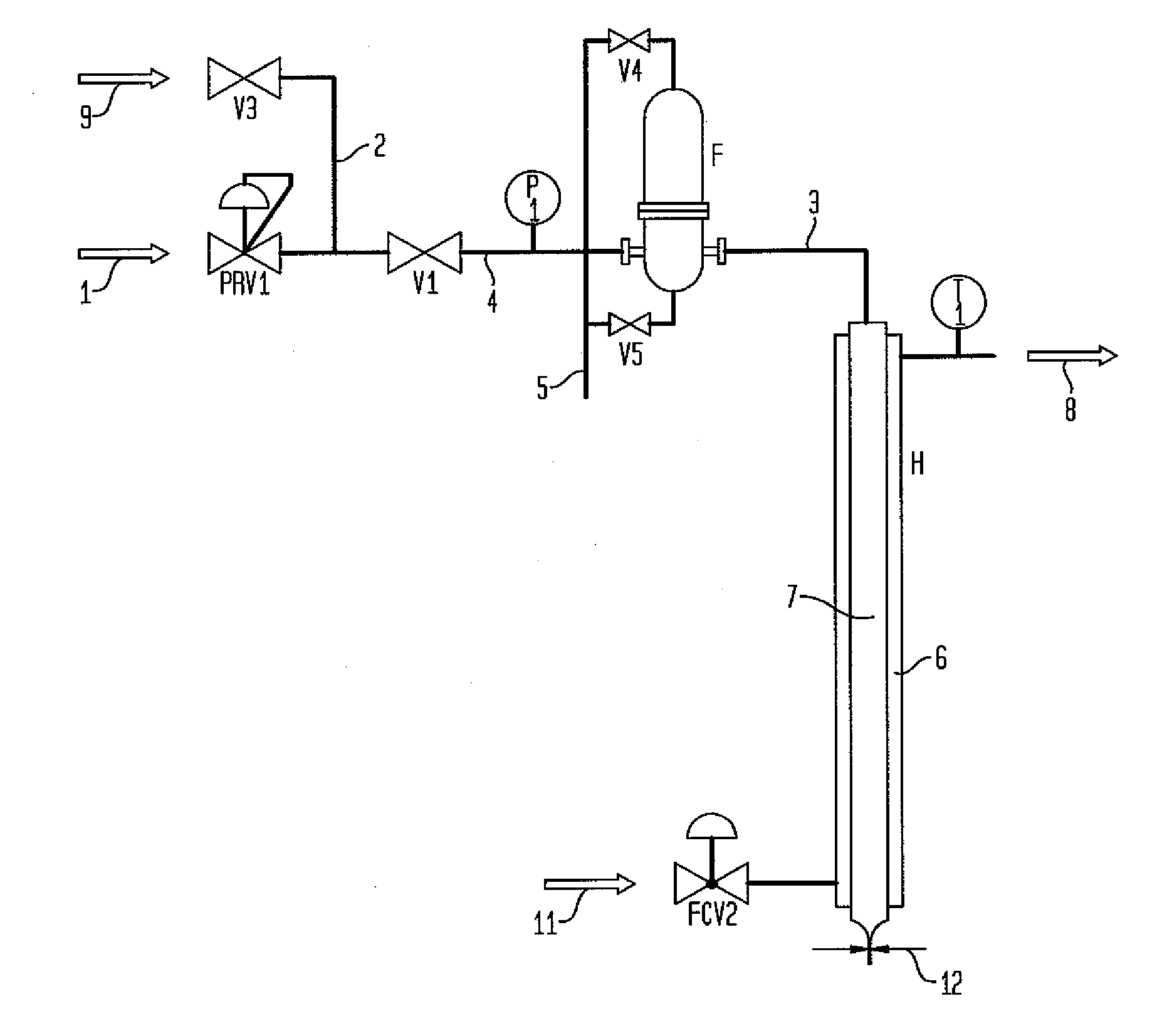

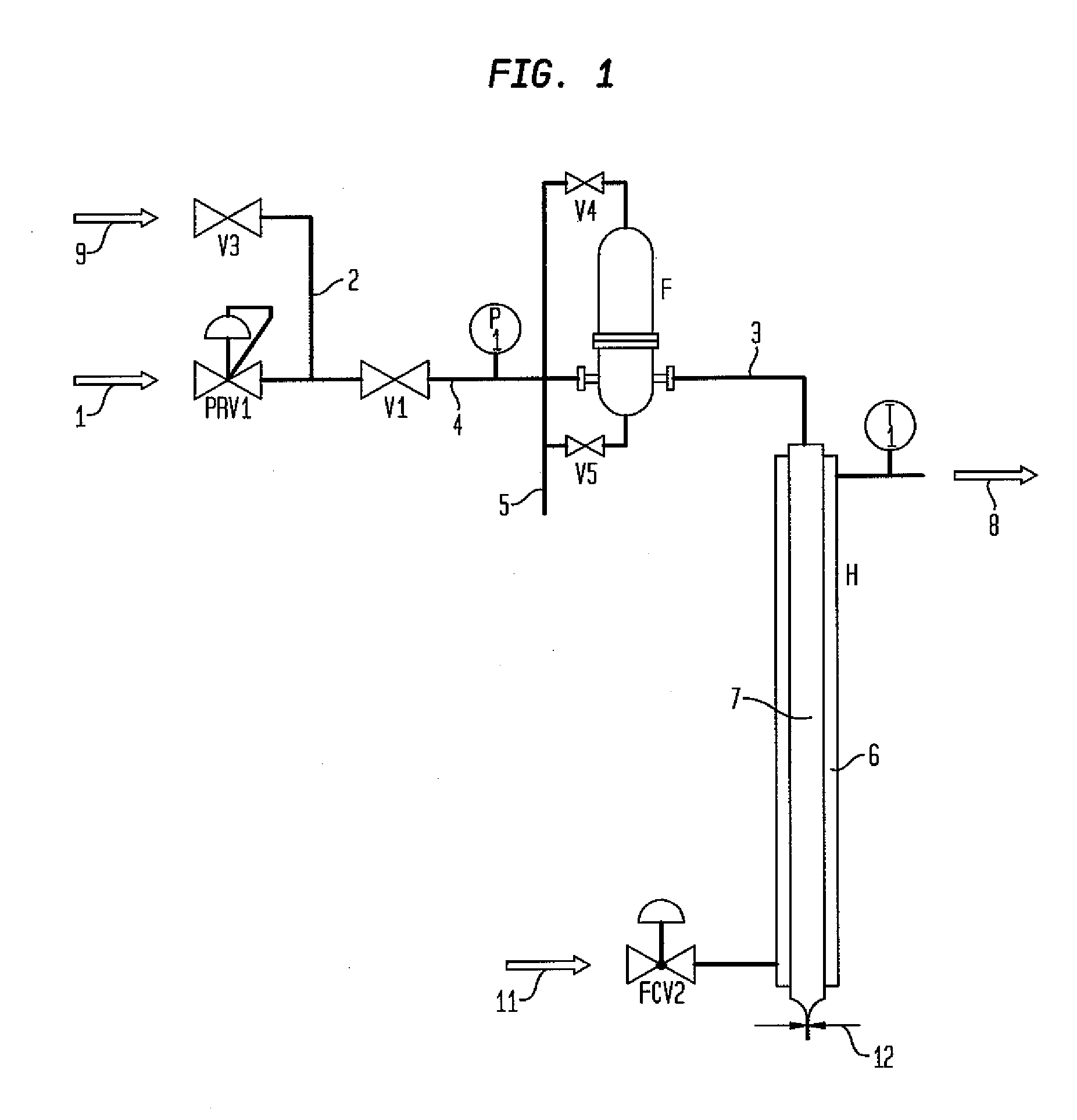

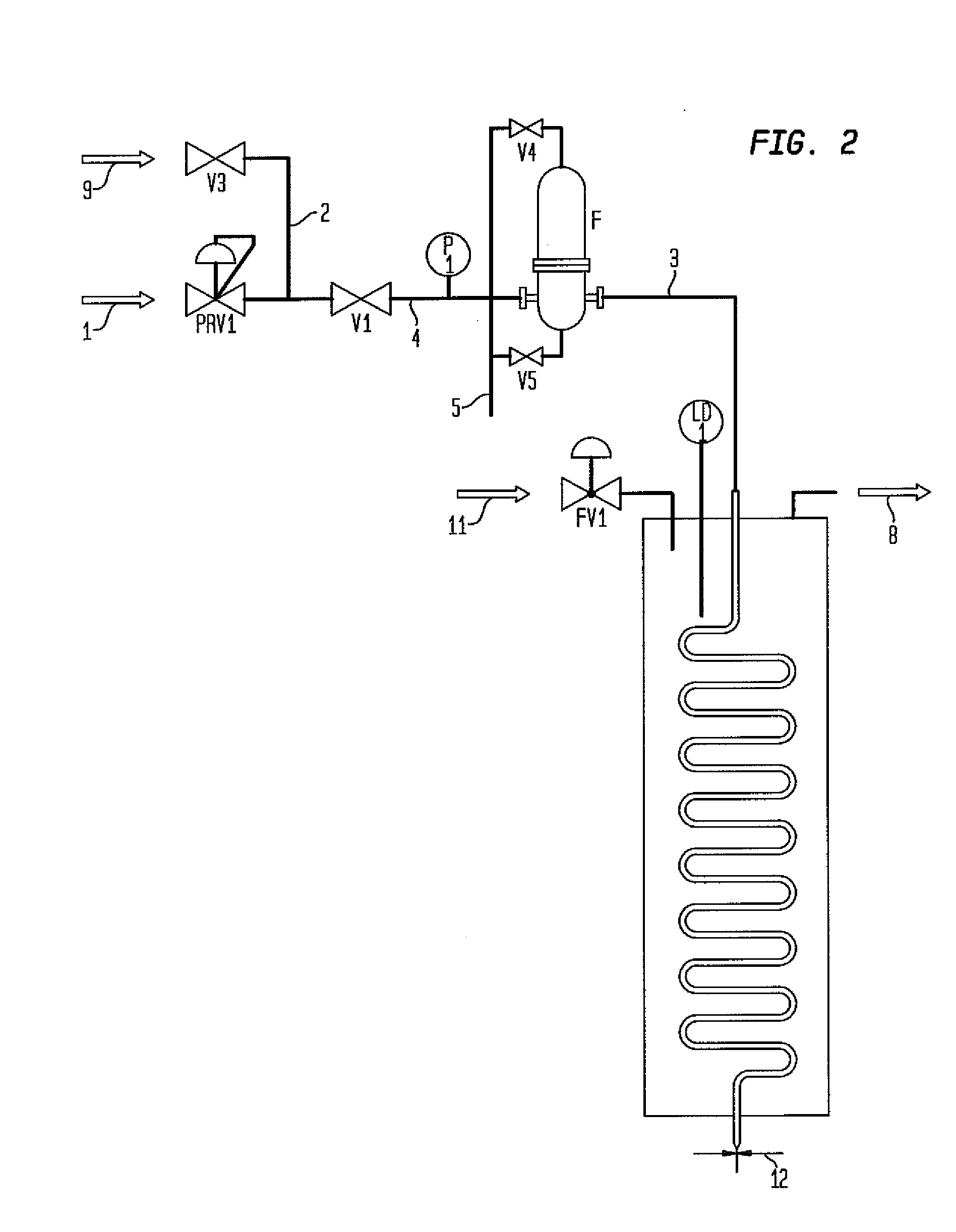

[0015]The method of the present invention is illustrated using a specific example. FIG. 1 provides a simple arrangement where the object is to produce a flow of sterile liquid nitrogen for delivery at atmospheric pressure. Normal gaseous nitrogen 1 at a predetermined pressure is fed through valve PRV1 to a standard sterilizing filter to produce a sterile nitrogen gas stream 3. This sterile nitrogen gas stream is then fed through a simple tube in tube heat exchanger H where it is liquefied 7 through indirect heat exchange with a liquid nitrogen cooling stream 6 which is at close to atmospheric pressure. The key element of the present invention is the smooth orifice 12 that is placed at the discharge of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com