Discarding sabot for guide and method for attachment of such sabots

a technology which is applied in the field of guiding sabots and sabots, can solve problems such as problems such as compliance, and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

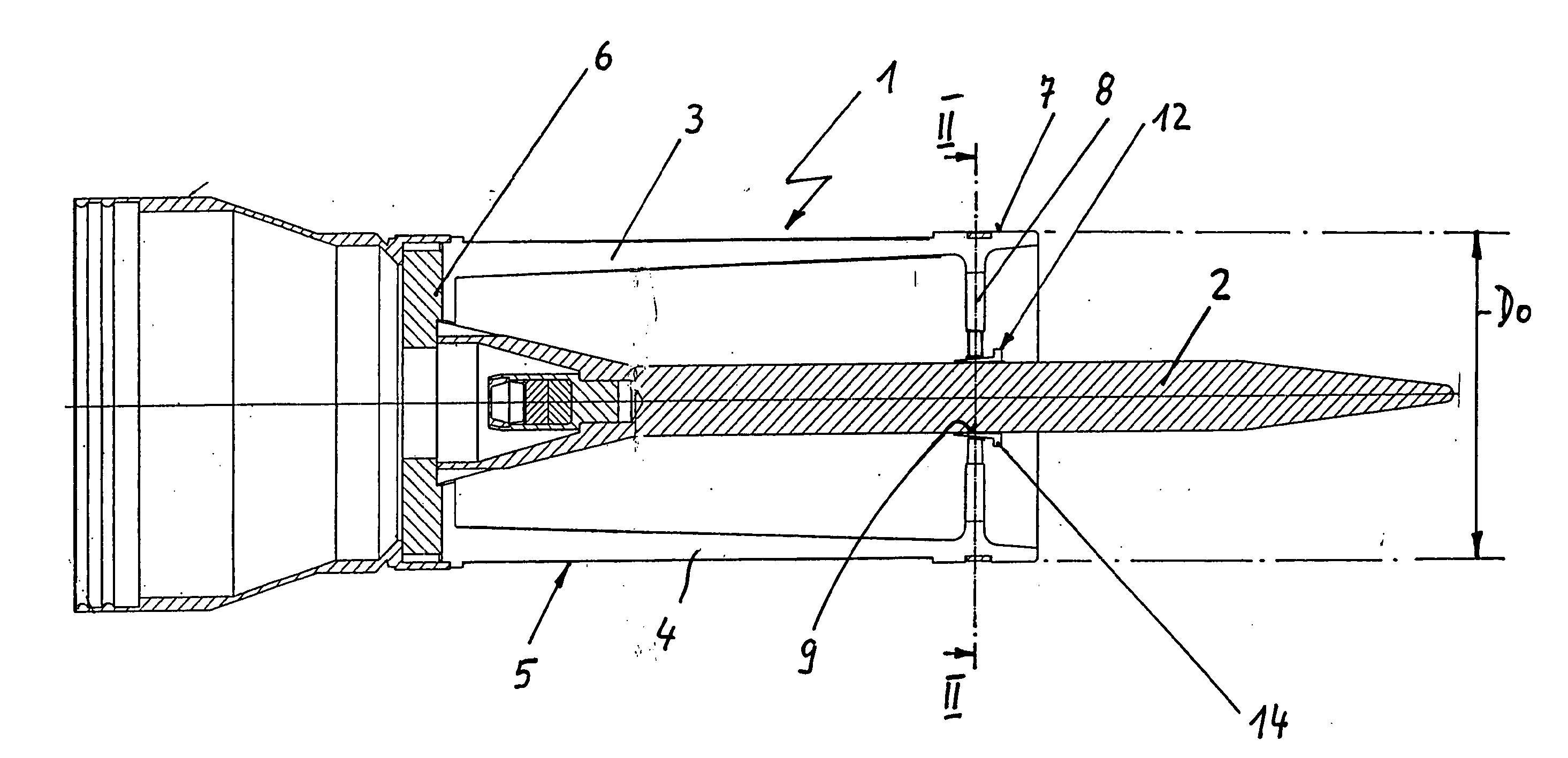

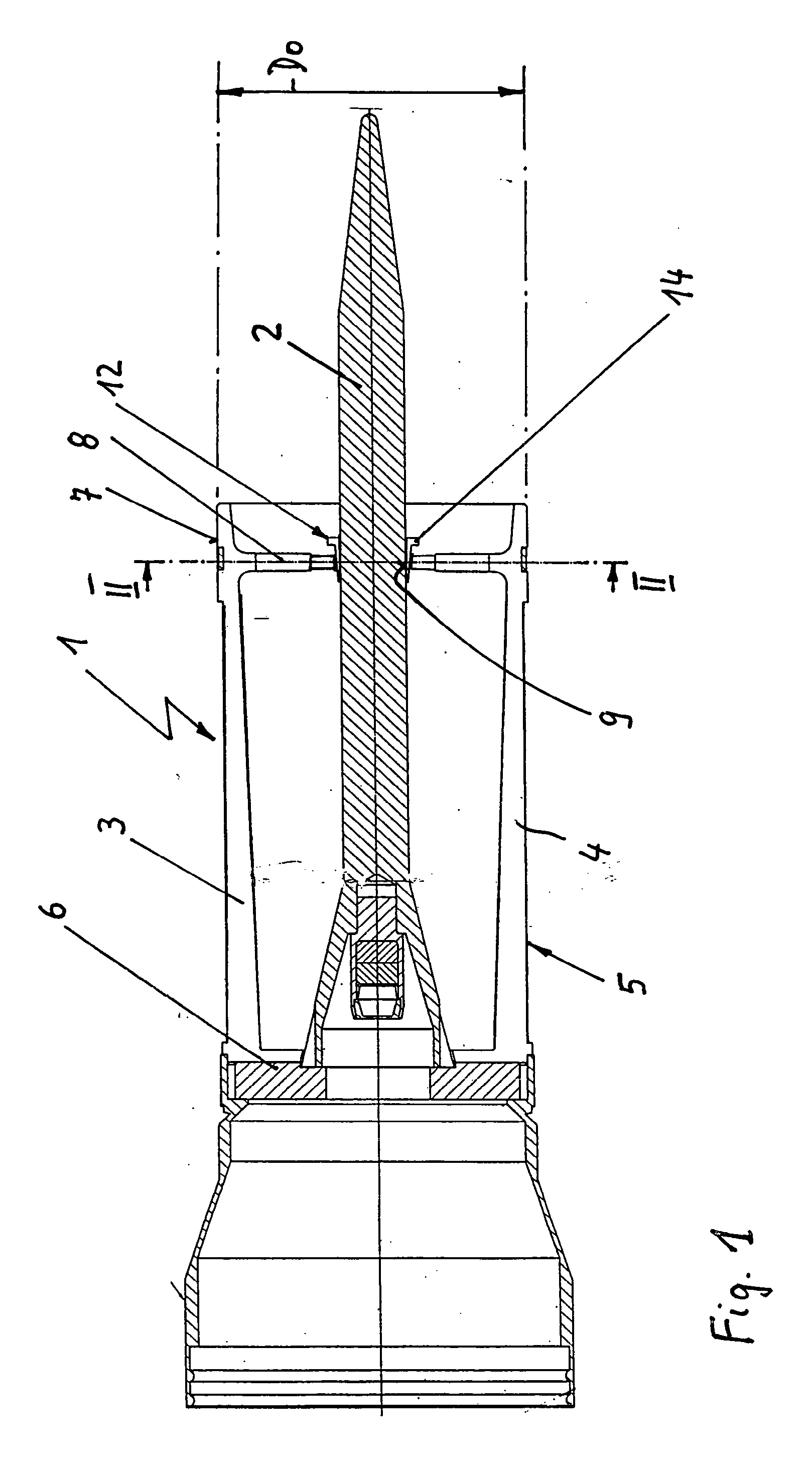

[0027]In FIGS. 1 and 4, 1 denotes a discarding-sabot projectile which, for example, is a 120 mm tank projectile that acts as a so-called discarding sabot (alternatively, however, it could also be a discarding sabot). The sabot projectile 1 has a sub-caliber projectile body 2, and an essentially hollow-cylindrical guide sabot 5, which comprises two half-shells (guide sabot segments) 3, 4. A drive disk (pusher plate) 6 is provided in the rear area in the guide sabot 5, and the projectile body 2 is supported on it at the rear.

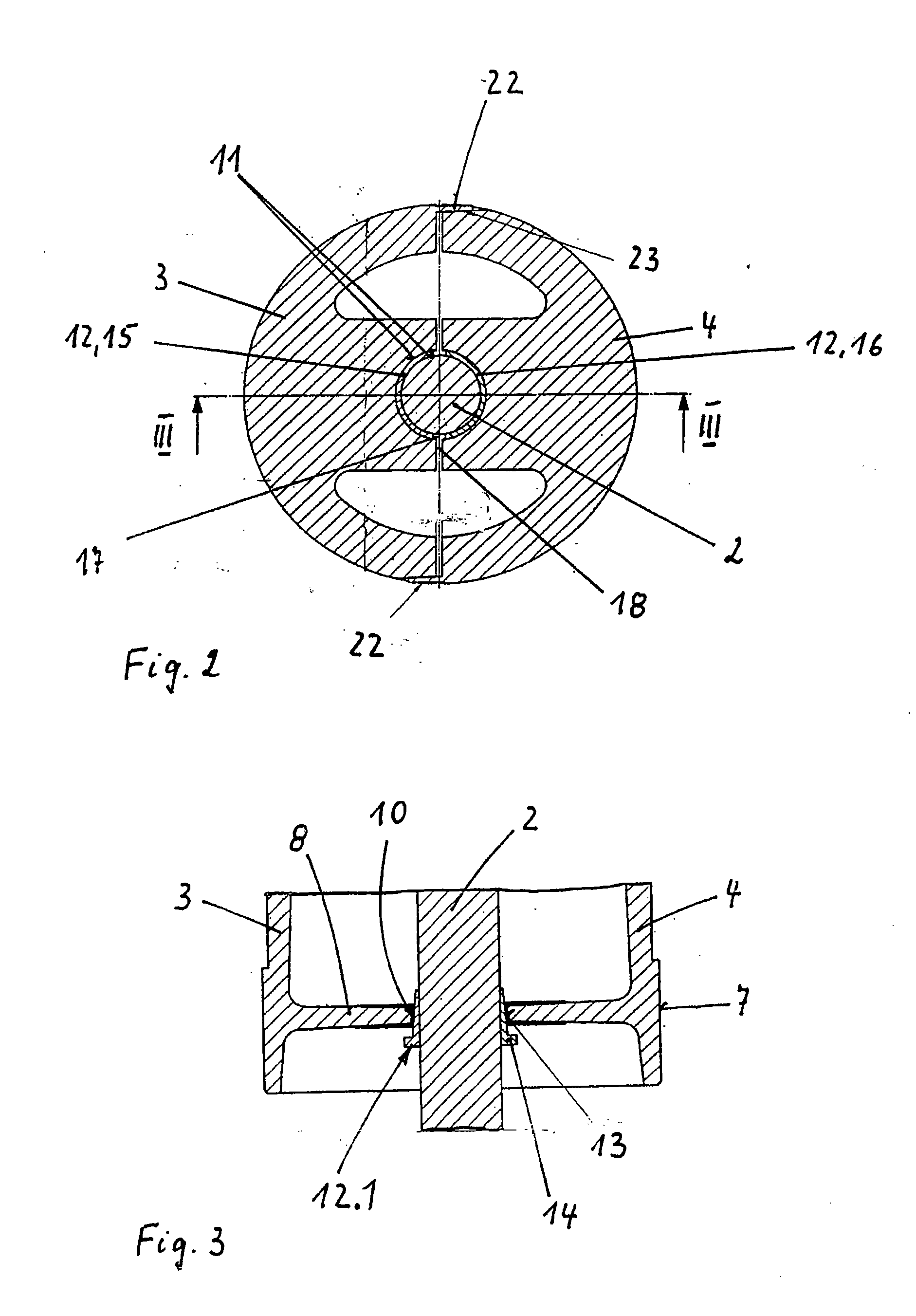

[0028]The guide sabot 5 is composed, for example, of plastic and, in its front area has a circumferential guide area 7, which projects on the outside, for support on the barrel inner wall of a weapon barrel, which is not illustrated. A (segmented) supporting wall 8 is also provided in the front area of the guide sabot 5, wherein the supporting wall 8 extends radially inward and has a central opening 9 through which the projectile body 2 is passed.

[0029]There is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com