Coated powder particles

a technology of powder particles and cyclopropene compound, which is applied in the direction of food preservation, pest control, plant growth regulators, etc., can solve the problems of unfavorable plant or plant parts contact, undesirable amounts of cyclopropene compound to be released into the atmosphere, and the cyclopropene compound to release too quickly from the encapsulation complex,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

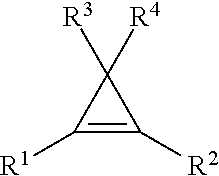

Image

Examples

example 1

[0082]Comparative Formulation CF11 was a comparative formulation, made using powder AP1 and other ingredients but no FC50. The concentration of 1-MCP in Comparative Formulation CF11 was 1% by weight, based on the weight of CF11. 0.06 gram of CF11 and 10 ml of SOL1 (to give a solution in which the concentration of 1-MCP was 50 mg per liter of solution.) were added to a 250 ml bottle. The release of 1-MCP was measured using procedure P2.

[0083]Formulation F12 was made as follows. Coated Powder was made using AP1 (10% by weight) and stearic acid (90% by weight) in Procedure P1. 0.2 gram of the coated powder was added to a 250 ml bottle containing 10 ml of SOL1. The amount of AP1 was chosen to yield a solution having approximately 50 mg of 1-MCP per liter of solution. The release of 1-MCP was measured using procedure P2.

[0084]Results were as follows:

CF11F12time (min)% 1-MPC releasedtime (min)% 1-MCP released3.5413176.55162610601033157015402076254625784053308660574093906350961206960100166...

example 2

Effect of Particle Size

[0085]Formulation F21 was made as follows. Coated Powder was made using AP1 (10% by weight) and WX1 (90% by weight) in Procedure P1, using conditions adjusted to yield coated powder with median particle diameter of 30 micrometers. The coated powder (0.14 gram) was added to a 250 ml bottle containing 10 ml of SOL1. The amount of AP1 was chosen to yield a formulation having approximately 50 mg of 1-MCP per liter of formulation.

[0086]Formulation F22 was made identically to F21, except that the conditions in Procedure P1 were chosen to yield coated powder with median particle diameter of 60 micrometers.

[0087]The formulations were tested by Procedure P2. Results were as follows:

F21 (30 micrometers)F22 (60 micrometerstime (min)% 1-MPC releasedtime (min)% 1-MCP released1020109303230166044602212053120301955919538120077120067

[0088]Formulation F22 had slower release of 1-MCP than Formulation F21.

example 3

Headspace in a Commercial Spray Tank

[0089]Tests were conducted using the tank of a Hardi™ ES-50 commercial sprayer. The capacity of the tank was 191 liter (50 gallon).

[0090]Comparative Formulation CF31 was identical to CF11. CF31 was added to 191 liters of tap water in the tank. Concentration of 1-MCP in the tank was 25 mg / liter.

[0091]Formulation F32 was made as follows. Coated Powder was made using AP1 (10% by weight), WX1 (89.5% by weight), and DP1 (0.5% DP1), using Procedure P1. The powder blend was made as follows: Coated powder was blended with 1.9% (by weight based on the weight of powder blend) SLS (powder) and 4.8% SS2 (by weight based on the weight of powder blend). 191 liter of tap water containing 0.025% SS1, by volume based on the volume of the tap water, was added to the tank. Then some of the water was removed and used to form a slurry with Formulation F32, and the slurry was then added to the remaining water in the tank, with agitation. Concentration of 1-MCP in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com