Carrier for a shaving device, comprising pairs of a cutting element and a hair lifting element

a shaving device and hair lifting technology, applied in the direction of metal working devices, etc., can solve the problem of reducing the effectiveness of the hair lifting process even further, and achieve the effect of optimizing the functioning of the hair lifting element and the cutting elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

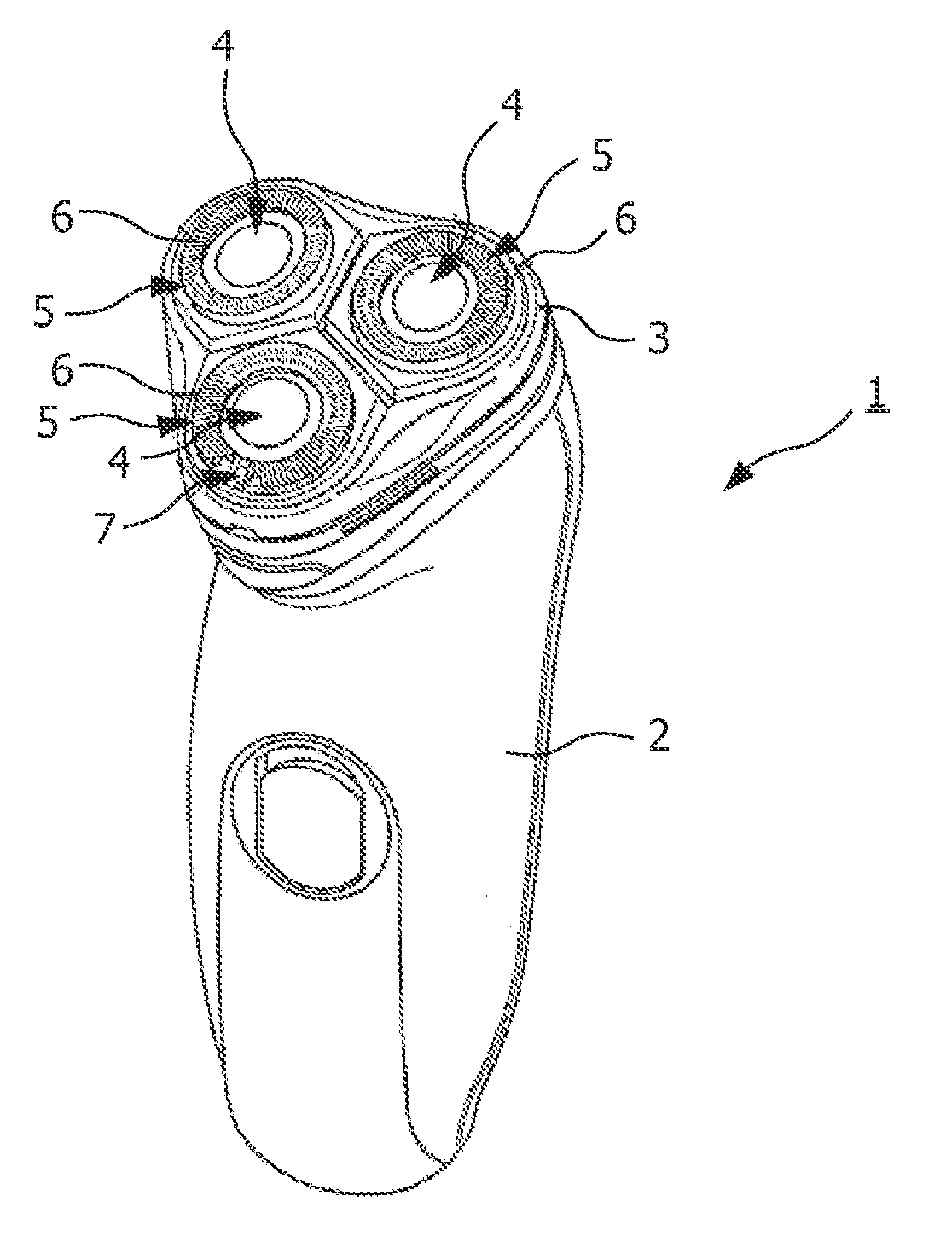

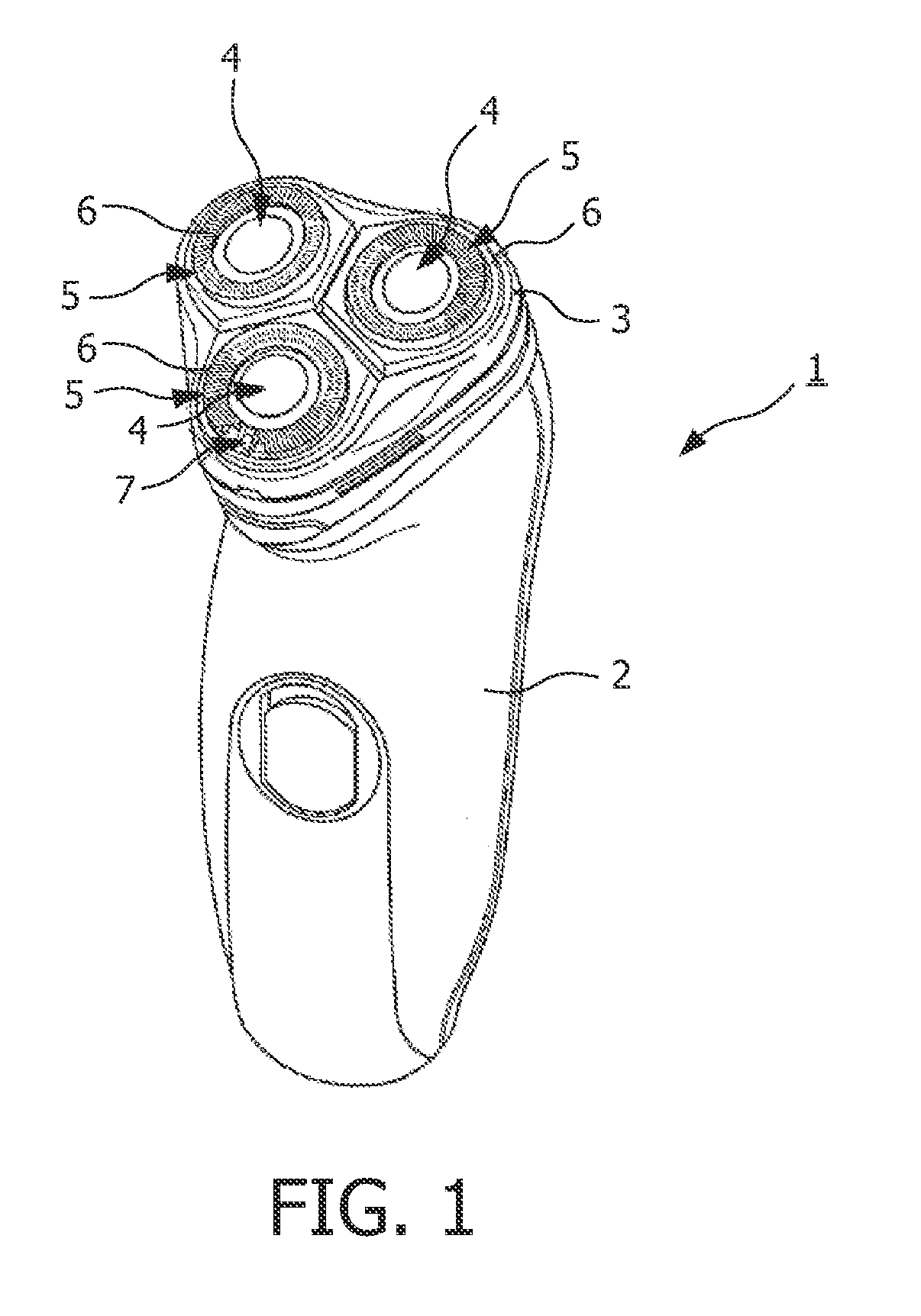

Image

Examples

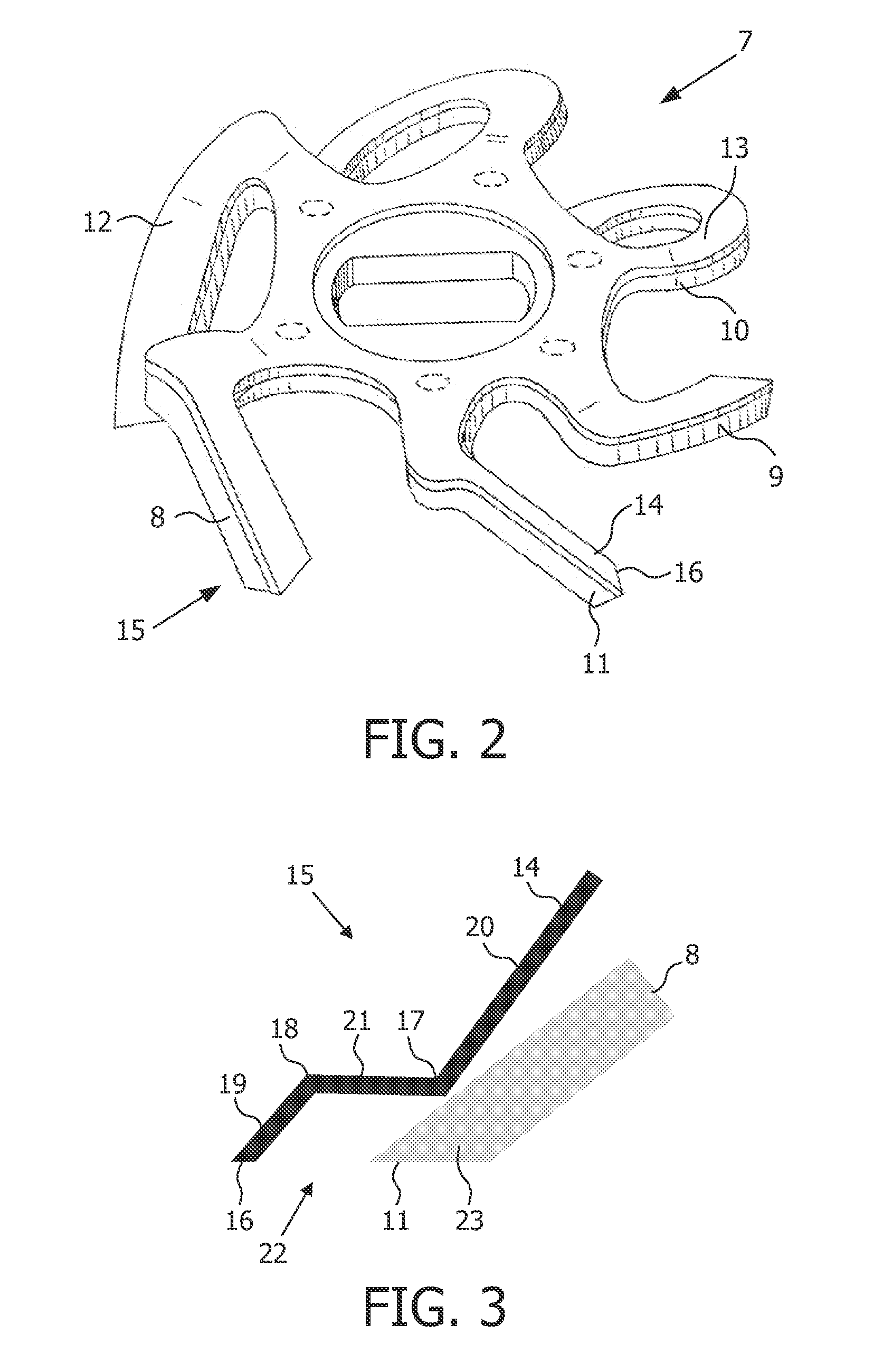

first embodiment

[0038]In principle, a shaving action can also be performed with the use of carriers 7 which are only equipped with cutting elements 8, wherein the hair lifting elements 14 are omitted. However, applying the hair lifting elements 14 leads to much better shaving results, as the hairs may be cut off at a level which is closer to the skin. The present invention is especially applicable in the field of carriers 7 having at least one pair 15 of a cutting element 8 and a hair lifting element 14, and will now be explained on the basis of FIGS. 3-8. In FIG. 3, a pair 15 of a cutting element 8 and a hair lifting element 14 according to the present invention is diagrammatically shown. In this embodiment, the hair lifting element 14 has a bent shape, wherein two bending lines 17, 18 are present in the hair lifting element 14, which extend across a width of the hair lifting element 14, substantially parallel to the outer edge 16. On the basis of the presence of the two bending lines 17, 18, thre...

second embodiment

[0046]The hair lifting element 14 does not necessarily need to be the element 8, 14 that is provided with bending lines 17, 18. In a second embodiment as shown in FIG. 5, the cutting element 8 has a bent appearance, whereas the hair lifting element 14 has a straight appearance. It is also possible that both elements 8, 14 are provided with two bending lines 17, 18, 26, 27, wherein, in a general sense, the shape of one of the elements 8, 14 is a mirror shape of another of the elements 8, 14. This possibility is shown in FIG. 6.

[0047]In the second embodiment as shown in FIG. 5, a connecting portion 28 of the cutting element 8 has an orientation that is substantially the same as an orientation of the hair lifting element 14. In this way, it is achieved that gliding contact of the hair lifting element 14 to the cutting element 8 is realized over a relatively large area. Nevertheless, an alternative to this configuration is also possible within the scope of the present invention, as can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com