Metal melting system and metal melting process with annular hot gas insulation layer

A technology of thermal insulation layer and hot gas layer, applied in metal smelting equipment and technology, metal melting system and metal melting technology field, can solve the problems of reducing the quality excellent rate, increasing production cost, reducing production efficiency, etc., so as to improve melting efficiency and isolate Heat dissipation and crack reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

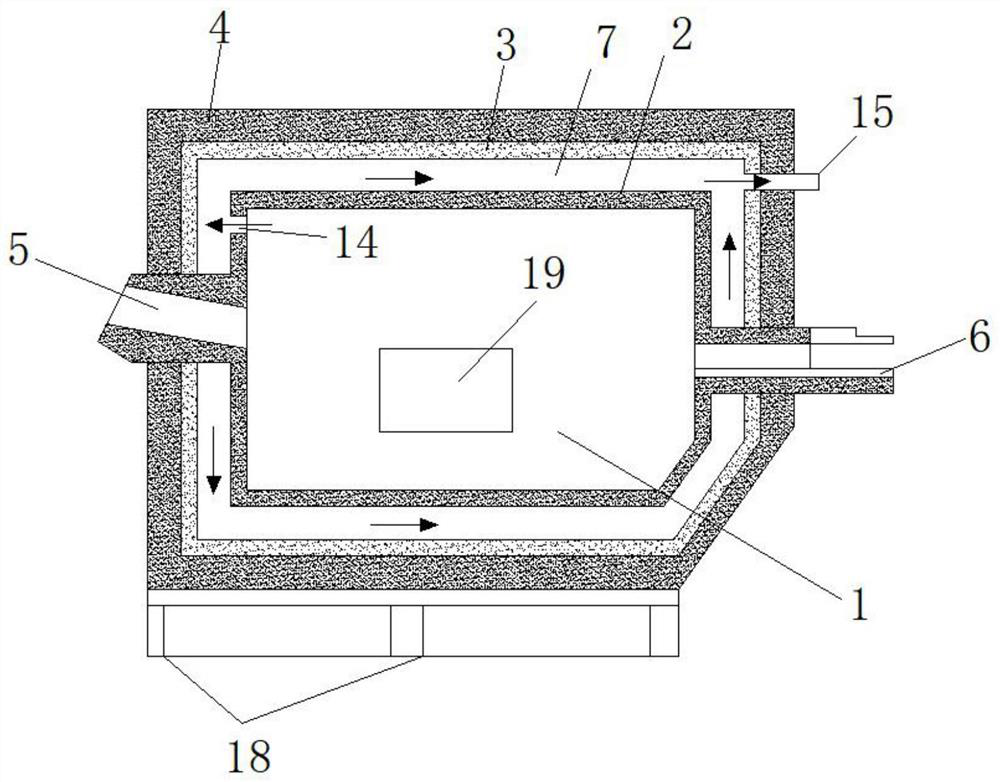

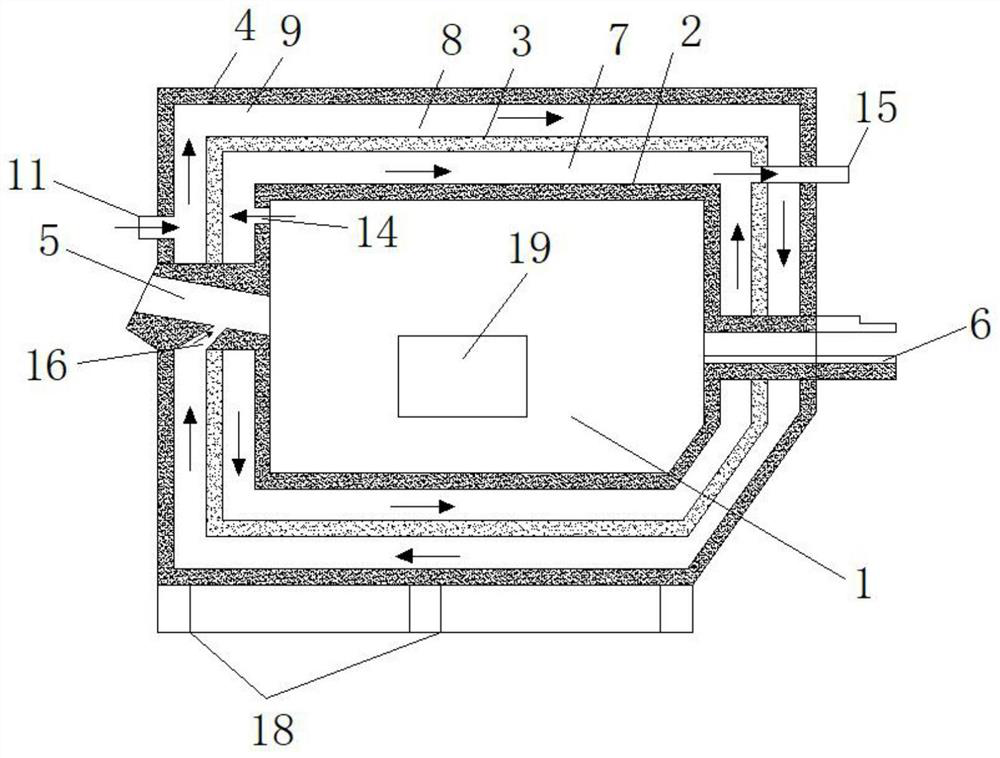

[0062] Such as figure 1 As shown, a metal melting system with an annular hot gas insulation layer, the system includes a melting furnace chamber 1, a furnace lining 2, an insulation layer 3, a furnace shell layer 4, a combustion device 5, a liquid outlet 6 and a feeding port 19. The cavity formed by the inner wall of the furnace lining 2 is the melting furnace cavity 1 . The outside of the furnace lining 2 is provided with an insulation layer 3 , and the outside of the insulation layer 3 is provided with a furnace shell 4 . The combustion device 5 passes through the furnace shell layer 4 , the insulation layer 3 , and the furnace lining 2 in sequence, and then communicates with the melting chamber 1 . The other side of the melting chamber 1 opposite to the combustion device 5 is provided with a liquid outlet 6 , and the liquid outlet 6 passes through the furnace lining 2 , the insulation layer 3 , and the furnace shell layer 4 sequentially and then communicates with the outsi...

Embodiment 2

[0064] Example 1 is repeated, except that the furnace lining 2 is integrally casted with refractory castables.

Embodiment 3

[0066] Repeat Example 2, the inner wall of the furnace lining 2 is painted with ZS-522 high temperature resistant self-cleaning non-stick coating (metal slag adhesion coating).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com